Printing cities: AECOM’s challenge to disrupt the stagnant industry

While 3D-printing technology has not yet prevailed in large-scale applications, AECOM is making a strategic move to disrupt the construction industry.

The first disruption in over 160 years

In 1849, Joseph Monier, a French gardener, invented reinforced concrete, concrete in which steel is embedded to resist forces, for the use of his concrete basins.1 The disruptive technology was immediately applied to floors, arches, and bridges, creating the foundation of modern construction.2 However, over the past 160 years, the construction industry has not undergone another major transformation.

As a result, the construction industry has registered disappointing efficiency gains, and its growth in labor productivity continues to lag far behind that of other industries.3 Concrete has to be poured on site, and it takes time for materials to settle. The entire process is still extremely labor-intensive.

The development of 3D printing, adding layers of a structural material instead of pouring concrete into a mold, is expected to make a disruptive impact to this over-a-century stagnation. AECOM, a fully integrated infrastructure firm, headquartered in California, has taken initiatives to launch architecture into a new era. “From recycling plastic waste into building material to reducing costs in obtaining modular building components during construction, the benefits of 3D printing could have major potential to disrupt the industry,” noted Michael S. Burke, a chairman and CEO of AECOM.4

The background

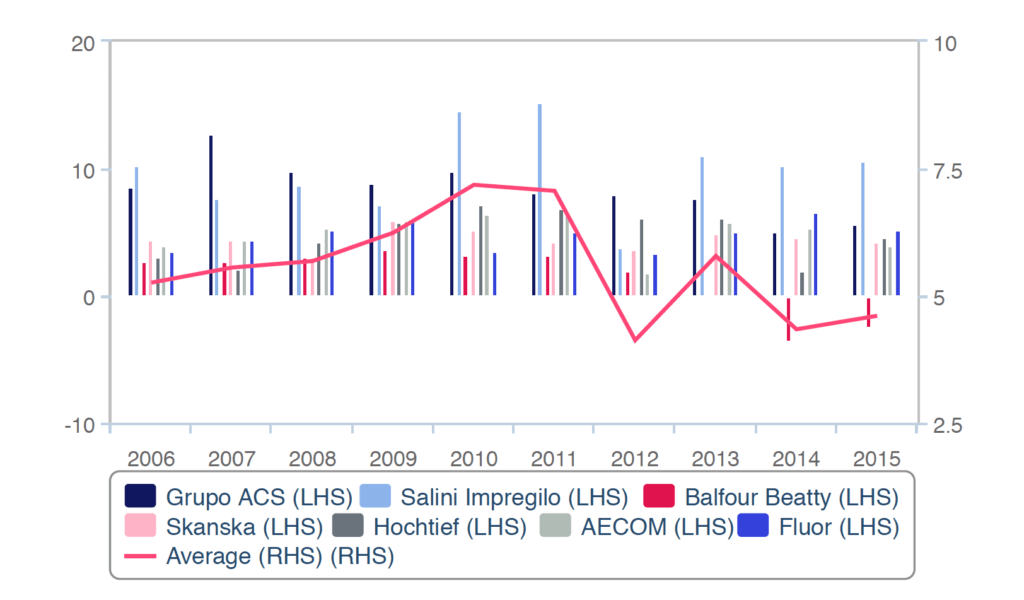

The lack of innovation has created fierce competition and has put enormous margin pressure on construction firms (see Figure 1). 3D printing technology enables companies to improve productivity by cutting labor costs through automated manufacturing process, together with reducing the amount of waste. Although additive manufacturing has been applied to a wide range of sectors, including the aerospace and automotive sectors, the application in the construction industry is still at an early stage. Several issues persist: (1) resolution problems (large-scale printing often produces rough results), (2) speed (big printing remains slow), and (3) high costs. Therefore, 3D printing has been mostly applied to low-volume, high-value parts.5

Figure 1: Select US and European Construction Firms’ EBITDA Margin (%)

Source: BMI Research6

AECOM’s track record

AECOM has been working with additive construction since 2011. The company focused on applying 3D printing for prefabricated construction, where pieces of buildings are made in factories before being shipped to a construction site. This application enabled the company to construct a series of cells for multiple prisons in the U.S. and various components for hospital rooms in Ohio.7 By 3-D printing jail cells out of concrete, AECOM can precisely place openings for plumbing and other fixtures, which is key to keeping the cells secure. 8

Strategic move

To accelerate the move in the short terms, in May 2017, AECOM signed a Memorandum of Understanding with a Chinese 3D printing company, WinSun. This agreement allowed AECOM and Winsun to pursue opportunities together for the next three years in order to deliver the benefits of 3D printing of buildings and their components to clients around the globe.9

AECOM is seeing potential collaborative project opportunities for clients in the Middle East with Winsun, which is one of the leading companies in the 3D printing industry, applying the technology for construction of full-scale buildings. WinSun’s technique involves extruding layers of concrete on top of one another, and the company recently announced it will lease concrete 3D printers to Saudi Arabia.10

In Middle East, AECOM is now embracing the challenge to fully manufacturing architecture, through building long-term relationships with the governments and construction companies with advanced technologies. The region is taking a lead to introduce the technology to build its cities. For example, Dubai Future Foundation announced that it “has launched the ‘Dubai 3D Printing Strategy’, a unique global initiative that aims to exploit technology for the service of humanity and promote the status of the UAE and Dubai as a leading hub of 3D printing technology by the year 2030.”11

The way forward

To ensure the leading position, AECOM should engage in two strategies.

(1) Acquire clients and projects in emerging markets (in the short terms)

Developing regions in Asia and Africa are expected to account for most of the world’s new urbanization in the coming decades.12 Besides the Middle East, which already took a strong initiative to build cities with 3D printing, AECOM should seek for the demand from these markets and communicate with both the government and investors.

(2) Invest in talent (in the medium terms)

Although the design process of architecture has been mostly digitalized, the design for the 3D printing construction requires different expertise.13 Because the technology is still new to the industry, there are not many experts who are able to create effective designs to improve productivity. AECOM should invest in developing such talents, which will become its key competitive advantage.

The construction industry is finally expecting a disruptive change. However, the industry is generally highly regulated by building codes. Will governments approve the new construction method, considering the existing regulations on safety and fire prevention? The wider application requires incremental changes in multiple fields.

(Word Count: 798)

Endnotes

0 Featured image: Corey Clarke, “AECOM Forms Agreement with WinSun To Use 3D Printing In Construction”, 3D Printing Industry, May 18, 1017, https://3dprintingindustry.com/news/aecom-forms-agreement-winsun-use-3d-printing-construction-113608/, accessed November 2018.

1 Encyclopedia Britannica, “Reinforced Concrete”, https://www.britannica.com/technology/reinforced-concrete, accessed November 2018.

2 Encyclopedia Britannica, “Joseph Monier”, https://www.britannica.com/biography/Joseph-Monier, accessed November 2018.

3 Excerpted from BCG, Philipp Gerbert , Santiago Castagnino , Christoph Rothballer , Andreas Renz , and Rainer Filitz,

“The Transformative Power of Building Information Modeling”, https://www.bcg.com/publications/2016/engineered-products-infrastructure-digital-transformative-power-building-information-modeling.aspx, accessed November 2018.

4 Excerpted from AECOM, Michael S. Burke, “Drones, virtual/mixed reality and 3D printing are the future of construction”, https://www.aecom.com/blog/drones-virtualmixed-reality-and-3d-printing-are-the-future-of-construction/, accessed November 2018.

5 World Economic Forum, “Shaping the Future of Construction: A Breakthrough in Mindset and Technology”, May 2016.

6 BMI Research, “Construction Disruption: Building Technologies In Focus“, August 2017, p.14.

7 Michael Molitch-Hou, “Additive Construction: From the 3D-Printed House to the 3D-Printed High-Rise”, engineering.com, May 31, 2018, https://www.engineering.com/3DPrinting/3DPrintingArticles/ArticleID/17038/Additive-Construction-From-the-3D-Printed-House-to-the-3D-Printed-High-Rise.aspx, accessed November 2018.

8 Christopher Mims, “3-D Printed Buildings Are a Tech Twist on Ancient Construction Techniques”, Wall Street Journal, April 1, 2018.

9 “AECOM signs Memorandum of Understanding with Winsun to collaborate on 3D printing for building design and construction”, PR Newswire Asia; New York, May 18, 2017.

10 Corey Clarke, “AECOM Forms Agreement with WinSun To Use 3D Printing In Construction”, 3D Printing Industry, May 18, 1017, https://3dprintingindustry.com/news/aecom-forms-agreement-winsun-use-3d-printing-construction-113608/, accessed November 2018.

11 Dubai Future Foundation, “Dubai 3D Printint Strategy”, https://www.dubaifuture.gov.ae/our-initiatives/dubai-3d-printing-strategy/?mod=article_inline, accessed November 2018.

12 “AECOM signs Memorandum of Understanding with Winsun to collaborate on 3D printing for building design and construction”, PR Newswire Asia; New York, May 18, 2017.

13 Michelle Bangert, “Design for 3D Printing”, applianceDESIGN October 2017, p.29.

Interesting article! I wonder how these new technologies, automating or improving the productivity of labor, are going to affect workers in the future, displacing maybe thousand of works that are not needed anymore. But, at the same time, these technologies enable developing countries to create more and better infrastructure for the same segments of people.

What an interesting article Taito! It’s on a topic very similar to mine so I am thrilled to hear your views as an expert! I have come to a very similar conclusion, that the construction industry is very slow to innovate and that 3D printing might be an amazing way to make it move slightly faster and solve some of the most important operational problems in the sector. You also brought up a very important point I had not thought about before – that regulators play a really important role in construction. I really hope that they will also embrace the change and not become the bottleneck in the innovating process… 🙂

Very interesting article! I knew little about the lack of innovation in the construction industry, so thank you for bringing that insight to light. I think what we may see is construction companies testing 3D printing as a proof-of-concept in countries with more lax regulations. If AECOM is able to successfully and safely build in countries in Asia or Africa where there may be more freedom to innovate – due to minimal regulations – they can later translate that work to more developed nations with stricter laws. Interested to see how this all moves forward! Particularly on the cost front. Infrastructure development, particularly in developing countries, is incredibly dependent on financing. If 3D printing can reduce costs, I think the implications could be huge for those countries.

Great article and overview of how the construction industry is (slowly) changing.

Your comment about “acquiring talents” left me wondering what impact this will have on existing staff. How much money and effort would it take to train engineers and technicians modelling “traditional buildings” to allow them to model “3D printable” buildings. Further, how is this addressed by schools and universities, to adapt to a shift in skill demand?

Also, the construction industry is very regulated by construction codes and buildings are heavily audited/inspected during and after construction. Are codes evolving in light of the new technologies that are emerging?

This is a great article – thanks for sharing. From your article, it definitely seems that the 3-D printing of buildings will revolutionize the construction industry – reducing labor costs, increasing productivity, and as a result, extending the market for homes to millions of homeless people around the globe – it’s incredibly inspiring!

To Julien’s point above, while construction is absolutely a highly-regulated industry, I argue that 3D printing will provide more precision and higher quality in construction. In fact, the Army has recently begun experiments in using 3D printing to “print” barracks and other buildings for forward troops – implying that they are just as safe, durable, and generally cheaper (62% reduction in required materials) than conventional buildings [1].

[1] Troy Carter, TechLink https://techlinkcenter.org/3d-printer-house-army/, accessed November 2018.

Thanks for the awesome article Taito! Truly appreciate your bonafide knowledge in the architecture space.

My question is mostly around which technology is more important: 3D printing or Modular Construction?

In some ways 3D printing is highly inefficient – very easy to setup and customize, but expensive with a long cycle time (production time). In this way, maybe a pre-fabricated approach would be more interesting – where modular components are assembled in a factory setting (super cost efficient) and then finished assembly on site (ideally minimal work here). Overall excellent post!

This is a very interesting article Taito, thanks for sharing! It is really exciting to see how 3D printing can change the construction industry and see how it can bring some interesting architecture design to reality. I believe that this will bring in more energy and excitements to the construction industry in the long run!

I think your comment on their short-term strategy is a very smart move. Emerging markets generally have more flexibility in trying out new techonologies as they are less limited by the “traditional” way. Moreover, they have a stronger incentive to be the “first” one to do something as this will be a good marketing campaign for the city.

As for the regulation, what I have in mind is more about the limitation on the materials that can used in 3D printing, and also how can the 3D printing piece be fit in the overall structure. Safety issue indeed can be a potential threat on how welcoming people are to using 3D printing in construction.