Can Additive Manufacturing become a powerful humanitarian technology?

Learn how 3D printing is revolutionizing disaster relief!

Billions of dollars are spent on relief logistics every year to get supplies from origin to disaster destinations. Relief supplies can take several weeks and often months to make their way to a disaster zone.

Field Ready, formed in 2014, is using 3D printing technology to change the way humanitarian aid is delivered. 3D printing allows them to create low cost solutions for health and sanitation to provide relief cheaper and faster exactly where it is needed.

Field Ready deploys teams to disaster zones to understand local needs to manufacture medical supplies, mechanical parts and other relief supplies. They focus on producing relatively simple objects, such as clips that close plastic sheets for shower stalls, replacement pump parts. Many of these items are small but they can account for a sizeable portion of goods brought into emergency and can be critical for effective use of other products. By virtually moving supply chains to the field, Field Ready is able to provide solutions that respond to local contexts with local materials.

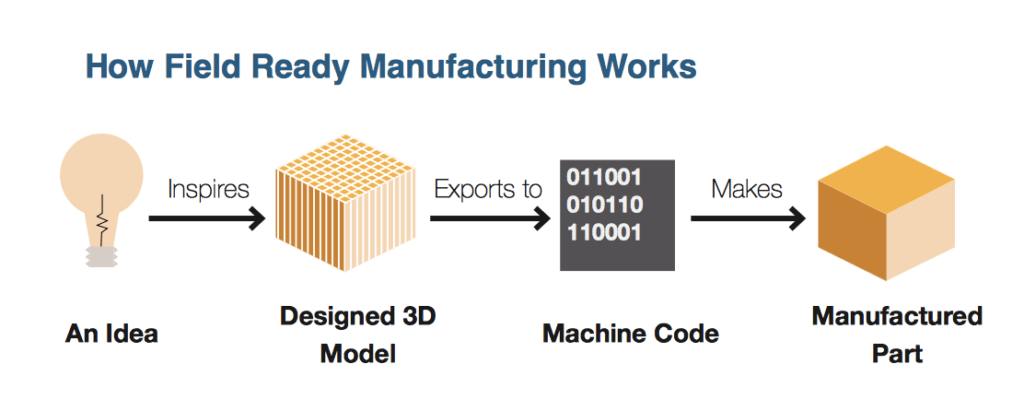

In situations when consumer needs are highly varied, 3D printing can be very advantageous in producing customized products based on actual demand, reducing waste. Faster production cycle enables them to proto-type multiple designs quickly. By the use of 3D printers and easy to share/ transport design files, Field Ready is able to fabricate and manufacture relief supplies within days at the disaster location, reducing logistic costs significantly. They can produce parts with minimal input material, further reading waste and input costs.

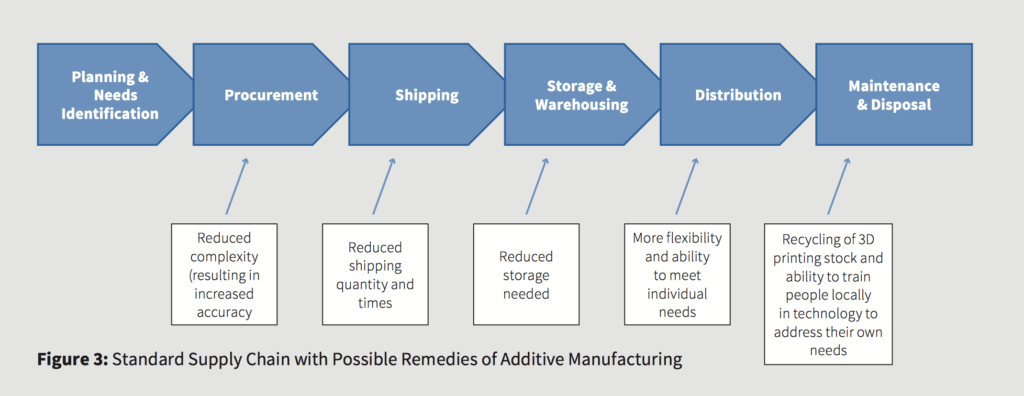

AM manufacturing shows a number of benefits including flexibility and adaptability due to the manufacturer’s proximity to the consumer and an ability to fine tune objects following the production of a prototype. Exhibit 1 shows a common framework for supply chains. 3D printing allows improvements, efficiencies and shortcuts at every phase, reducing time, space requirements with greater flexibility.

“It’s not about producing millions of things, it’s about producing the right thing so you can get whole things back online again” says Dara Dotz, co-founder of Field Ready.

Field Ready uses easy set-up, raw materials available in the local community to produce simple supplies. Their approach involves making and testing designs closely with the people who will use them, reducing the risk that too much is invested in an inappropriate design. In early 2017, Field Ready identified a broken suction pump in Gorkha, Nepal that would have taken weeks and hundreds of dollars in parts and procurement time to replace using the original part shipped from another city. Within an hour of arriving at the site, Field Ready’s team had measured, designed and printed a replacement connector piece. The print cost under a dollar in materials and took 45 minutes to design and print.

Additive manufacturing’ biggest challenge lies in sourcing trained engineers to design solutions needed in the field. In the short term, Field Ready is evaluating and improving skills for 3D printing – establishing design rules and creating design libraries to allow designers to share design files easily. Field Ready is using digital technologies to share open source designs and readily accessible manufacturing techniques.

Additionally, Field Ready is leveraging local manufacturers’ expertise to design parts. For example, while working in Nepal, Field Ready worked with a small local business to design cook stoves using 3D printing. Field Ready partners with local manufacturing to reduce the cost of global supply chains used in relief and also helps improve economic activity in the local economy.

While 3D Printing in remote areas can often be a good fit for shortcutting supply chains and speeding up access, it has limitations when it comes to creating high volume parts. 3D printing is presently too slow to print a large number of parts, which are typically needed in humanitarian settings. 3D printing is useful for producing replacement parts, but currently it does not have the capability to supersede the quantity of production that is achievable in a traditional supply chain.

Medium to long term challenges include applying this technology to produce massive construction items to help with shelter and clothing production to further improve post-disaster rehabilitation. Field Ready should investigate the resources that will be needed to design and manufacture complex products.

Field Ready should develop training guide to educate local people to use 3D printers. With local operators and design files sent from engineers, Field Ready can reduce the need and cost of having engineers deployed to disaster zones for long periods of time. Field Ready should empower local organizations and develop teams on the ground for long term use of 3D printing.

Like any new technology, itremains to be seen how feasible and cost-effective it is to ship 3D printers to a disaster-hit area.Can 3D printing stretch beyond simply serving immediate relief needs? (800 words)

Exhibit 1: Standard Supply Chain with Addictive Manufacturing Benefits

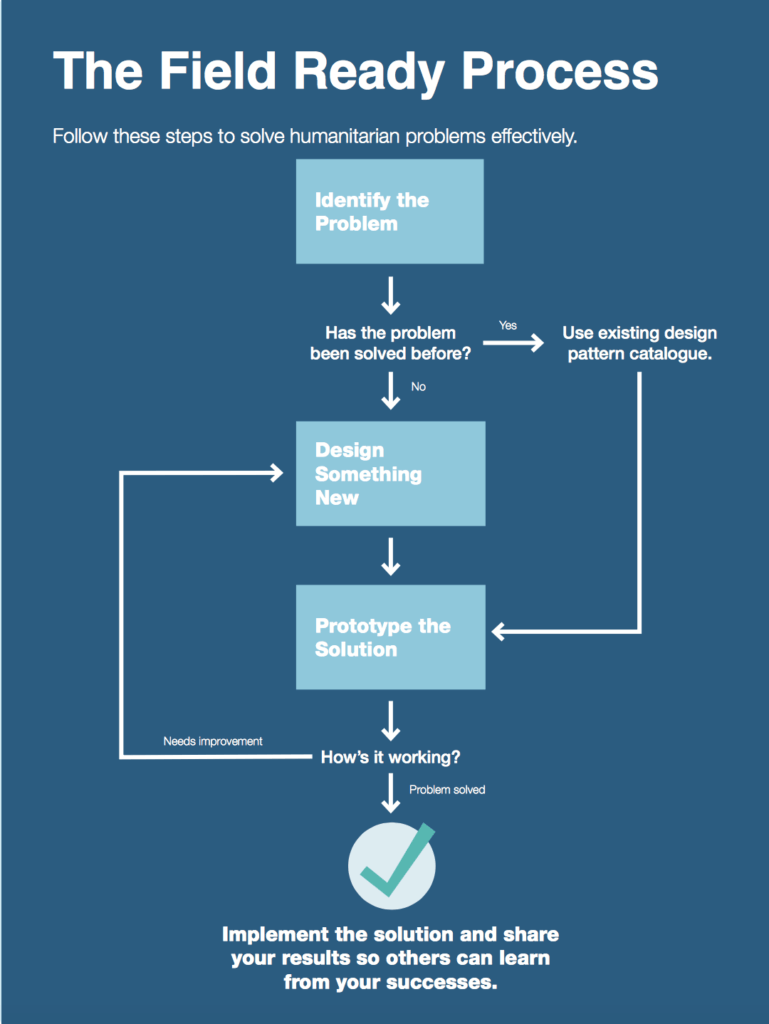

Exhibit 2: Field Ready Process

Sources:

- https://www.fieldready.org

- https://www2.deloitte.com/insights/us/en/deloitte-review/issue-19/3d-printing-for-humanitarian-action.html

- UN office of the Coordination of Humanitarian Affairs Paper “Shrinking the Supply Chain and 3D printing in Humanitarian Response”

- IEEE Paper “Opportunities and Challenges of Distributed Manufacturing for Humanitarian Response”

- “3D printing for Disaster Preparedness – Making Life-saving supplies On-Site, On-Demand, On-Time”. Authors: Srinivas Saripalle, Humanitarian Maker, Co-Founder & VP (Technology), Random Designs CA, Inc., Senior Member-IEEE (Author)

This is a really interesting application of AM which is quite different from what we’ve seen in other commercial applications. I like your recommendation of encouraging Field Ready to develop training programs to empower locals to use 3D printers. This also serves a mutual benefit to them since you’ve highlighted that AM’s biggest challenge lies in finding trained engineers to design solutions. I would love to understand who Field Ready’s investors are and the organization’s relationships with local NGOs/foundations since I think this would help to address your open question of how feasible and cost-effective this solution could be in the long term. I could also envision a world where Field Ready works closely with local governments to leverage existing infrastructure to reach disaster-hit areas cheaply and quickly.

KT —

I really enjoyed your article on how 3D printing is assisting with disaster relief. Thank you for shedding light on a company that is paving the way for providing supplies in disaster-affected areas. I understand the challenge posed in your question, and I think that the major drawback for additive manufacturing is the inability to mass-produce. While customization and development of replacement parts are crucial for disaster relief as well, it would be a significant improvement if supplies could be produced more quickly and efficiently in cases where many supplies are needed. You mentioned educating locals, and I believe that by improving the skills gap with AM, products could be developed much more quickly, helping with the mass production issue. I wonder, also, how to lower the cost of 3D printing and the software associated with it to allow locals to experiment with this technology. Thanks!

Science fiction!! This is incredible.

—

You asked “Can 3D printing stretch beyond simply serving immediate relief need?”, and I wondered “should it?”.

I think that immediate, one-off, needs make a tremendous market. Is there a reason the company to move to mass production if tailor-made solutions bring it enough customers?

Thanks for sharing, this is very interesting and a great use-case for 3-D printing! I agree that investing in local talent to become users of the technology would be very valuable in expanding the company’s reach. One of the prime benefits of additive manufacturing is the fact that in many cases it enables manufacturing to become almost hyper-localized (on a small scale). It will be interesting to see how the Field Ready team tries to scale / help with more humanitarian need for high volumes / large items as your essay states… perhaps they can start out as a more niche offering and then try to build a more robust manufacturing presence either organically or through partnership in a few key locations? Regardless of what they do, this is a great use of additive manufacturing and I’m happy to read about the positive impact made due to this megatrend!

The use of this technology in helping with disaster relief is truly inspiring – thank you for sharing! I wonder if Field Ready can leverage learnings from one disaster relief occasion to implement into other regions that are newly impacted. This may help foster a faster relief system, although I am certain there will always be unique local product needs. I also like the training aspect of the platform as disaster prone areas typically see recurrence of severe events (bangladesh lands eroding away via flooding for example). Via training, the company can ensure the methodology scales over time quicker, although I am not sure if the costs associated with training is a sustainable one for the business.

Very interesting and relevant example of use of additive manufacturing! As you described, 3D printing has great advantages in disaster relief: flexibility around inputs, speed, adaptability around design and waste reduction. The idea of having a vast library of designs developed through open innovation is very helpful — as data accumulates, the necessity to have experts on the ground decreases which makes the project more easily scalable!

KT – what a cool concept! I’m curious how they’ve designed this product to work in emergency situations. For example, does it run without electricity, which I would imagine is a constraint that exists in most emergency response scenarios? How accessible is the real-time transfer of design files in the (presumed) absence of internet immediately after a catastrophe? Or is this product meant to serve communities slightly after the “first responder” scenario?

In any case, it is incredibly interesting and seems to hold a lot of promise for both disaster-struck communities, as well as rural / isolated areas that lack easy access to important goods on a more sustained basis.

This is a great application of AM – and I am curious to see if there is a way to teach specific companies in developing nations a way to design their own AM processes so they are able to grow this technology and integrate it into their own production processes. I am also curious to see how the raw materials for each printed product are sourced and if this is potentially the key bottleneck in this production process (or if it is the technology that slows down production or advancement of this technology).