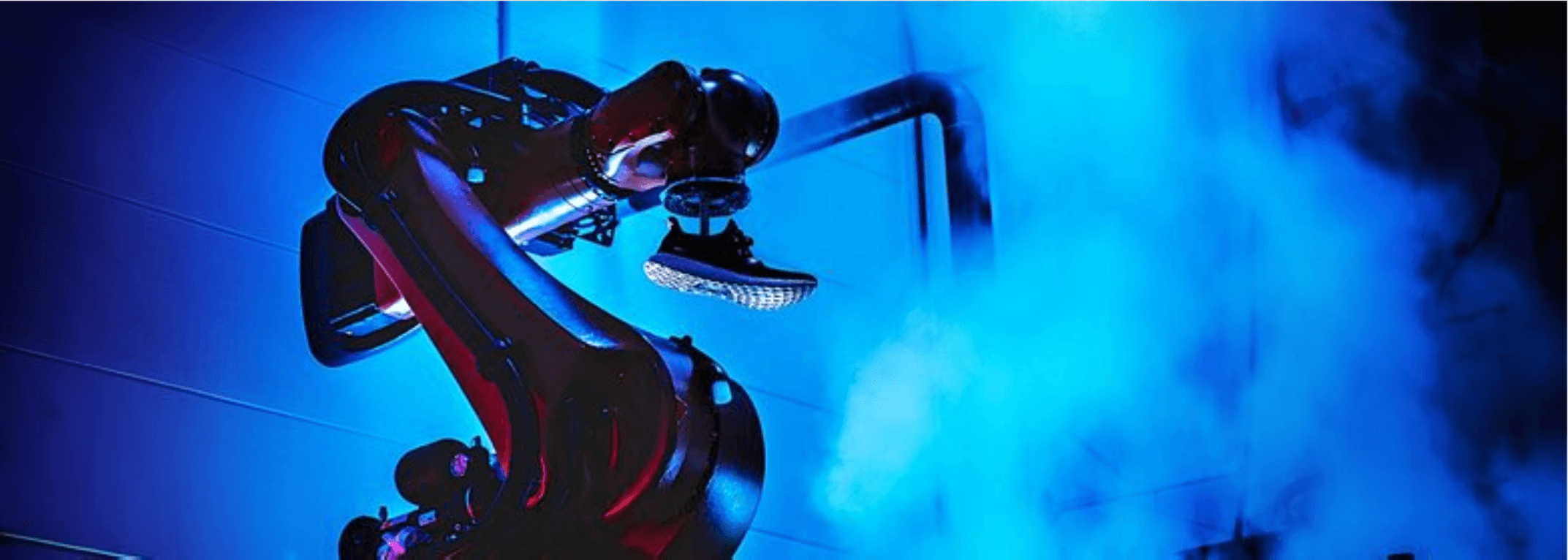

Adidas SpeedFactory: “Shoe”rtening Its Supply Chain with 3D Printing

Is the promise of 3D printing finally becoming an operational reality? Here's how Adidas is using 3D Printing to re-imagine its supply chain.

In today’s consumer-centric world of fast fashion and high performance, quickly adapting to changing preferences lies at the core of Darwinian survival. Companies that provide customized goods must enhance supply chain methodologies to allow for a faster go-to market strategy, thereby reducing lag-time between customer orders and delivery. Failure to do so would result in consumer demand moving in an unsynchronized manner with a firm’s production, thereby making it difficult to maintain or grow market share or even incur large capital expenditures for production, given the delay between investment and harvesting phases. A key question for managers is: How can companies become first-movers in how they supply highly customized goods to customers in the age of digitization?

At Adidas, management has embraced 3D printing as a means to shorten its supply chain and better match supply and demand, while providing superior durability and athletic performance. While 3D printing offers many benefits to Adidas in lowering R&D expense, accelerating its prototyping phase and providing higher quality trainers, such as those with “honeycomb” nano-structure shock absorption technology [1], this essay focuses primarily on benefits from post-design supply chain optimization.

In 2015, Adidas management introduced its SpeedFactory project, piloted in Ansbach Germany, which set to create several 3D-printing, automated production sites in various cities around the world to locally address its customers’ needs [2]. In the short and medium term, Adidas hopes to tackle its traditional supply chain by harnessing the following principles:

- Just-in-Time (JIT) Production & Flexibility: By shifting the site of manufacturing closer to consumers and through JIT 3D printing with tiny white plastic beads [3], Adidas can manufacture without incurring large delays. Thus it can avoid large finished goods inventories of trainers that may quickly go out of style. Furthermore, the generic nature of the white beads as a production input allows its multi-purpose use across several shoe styles, thereby also reducing the raw material inventory. Adidas is set to begin production in 2017, eventually producing 500,000 shoes a year. [4]

- Lower Shipping Costs: Traditionally, different parts of the trainer were manufactured in different areas, then assembled and shipped to the consumer. A recent article states, “An order to replenish an existing, in-demand design…can take two or three months to reach shelves, unless the shoes travel not in a shipping container but a huge cost in the hold of an aircraft.” [4] By producing closer to the consumer through 3D printing with generic inputs, Adidas can avoid large shipping costs between various points in its supply chain. It will likely only incur the shipping cost for raw materials, since highest percentage of the shoe’s final production would occur at a local SpeedFactory site.

- More Efficient D2C Channel: At a local SpeedFactory, Adidas can design and produce its trainer around particular geographic conditions, such heavy-rain [5]. This provides a higher-quality product with more variety, fewer delays, and better responsiveness to local consumer demand. Moreover, trainers can be on the market for a longer selling period given faster production.

In the long-term, Adidas could plan to de-centralize further, shifting to retail stores and other more intimate outlets allowing customers to customize and manufacture at the point of sale.

Recommendation:

Adidas’ supply chain will drastically change given the initiatives it has undertaken. Given the above bottleneck and costs may be greatly reduced, the bottleneck may shift to the design phase, thereby creating a need to reduce or parallel process various design phase elements.

- Complement Data Analytics with Existing 3D Printing Technology: Using data analytics to discern particular trends may accelerate the time it takes to design the product, allow for more versatility in the product that can be printed or spot problems earlier in the supply chain, much like GE spotted in its jet engine components.[6]

- Implant Sensors in Shoes to Discern User Activity: By understanding which designs lead to better performance based on user activity, Adidas can focus on harnessing designs quickly and can do so in parallel with one another.

- Adopt an Efficient Test & Learn Strategy: Adidas can put products out quickly and conduct A/B testing to discern which products are superior. The speed benefit from Adidas’ compressed supply chain can allow for better and faster testing and iteration, which can further set it apart from competitors.

A recent HBR article writes that in 500 days the hearing aid industry was able to convert to 100% 3D manufacturing [7]. Failure to be a first-mover in mainstream production can be hard to recover from. While companies like Adidas, which require a fast time-to-market strategy, are embracing 3D printing, two aspects still linger. Can 3D printing become truly scalable and mass market for Adidas? Additionally, how will Adidas’ supply chain cope with cybersecurity and hacking threats?

(791 words)

[1] Katherine Bourzac, “3-D-Printed Sneakers, Tailored to Your Foot” April 7, 2017, MIT Technology Review, https://www.technologyreview.com/s/604058/3-d-printed-sneakers-tailored-to-your-foot/, accessed November 12, 2017.

[2] Adidas, “From Robots To Your Home: Adidas’ First SpeedFactory Lands in Germany” December 9, 2015, http://news.adidas.com/us/Latest-News/-From-Robots-To-Your-Home–adidas–First-Speedfactory-Lands-In-Germany/s/f4d890b6-e38d-4a32-b20d-ebc9683972ec, accessed November 12, 2017.

[3] Richard Weiss, “Adidas Brings the Fast Shoe Revolution One Step Closer” October 5, 2017, Bloomberg Businessweek, https://www.bloomberg.com/news/articles/2017-10-05/adidas-brings-the-fast-shoe-revolution-one-step-closer, accessed November 12, 2017.

[4] The Economist, “Adidas’s high-tech factory brings production back to Germany: Making trainers with robots and 3D printers” January 14, 2017, https://www.economist.com/news/business/21714394-making-trainers-robots-and-3d-printers-adidass-high-tech-factory-brings-production-back, accessed November 12, 2017.

[5] Stephanie Pandolph, “Adidas uses Speedfactory to localize shoe designs” October 9, 2017, Business Insider, http://www.businessinsider.com/adidas-uses-speedfactory-to-localize-shoe-designs-2017-10, accessed November 12, 2017.

[6] Tomas Kellner, “Big Data Meets 3-D Printing: Big Data to Monitor Laser-Printed Jet Engine Parts” June 4, 2013, General Electric, https://www.ge.com/reports/post/77209216443/big-data-meets-3-d-printing-big-data-to-monitor/, accessed November 12, 2017.

[7] Richard D’Aveni, “The 3-D Printing Revolution” May 2015, Harvard Business Review,

https://hbr.org/2015/05/the-3-d-printing-revolution, accessed November 12, 2017.

[8] Feature Image: Adidas, “FutureCraft.4D” http://www.adidas.com/us/futurecraft, accessed November 15, 2017.

I really enjoyed reading this, TOMsupplychain! I too have questions about the scalability of 3D printing for Adidas. In particular, if Adidas were to move towards 3D printing at the point of sale, as the article mentions, what are the training implications? Assuming that there would be a designated individual or team at each store who would learn how to operate this machine, I’d imagine the learning curve to be incredibly complex for a store employee. Second, with the amount of turnover that occurs in this environment, I’d question whether or not the on-site training is even worth it. Third, the investment cost (and accompanying security costs) to hold one of these machines in a store would be significant.

On a separate note, I’m curious how Adidas plans to adjust their inventory levels. The article notes that 3D printing allows for more flexibility and a longer selling period, which are two great benefits of this innovation. However, how will Adidas go about reimagining its inventory investment? How long should products stay on the selling floor for? Will there be too much inventory variety and customization?

Finally, I’m concerned about the quality of the footwear being created from this 3D printer. I’d like to learn more about the pilot and what testing the company did to ensure that the same level of quality and functionality found in other Adidas products is met or exceeded.

Interesting read about how Adidas wants to leverage technology to make “locally produced” footwear and economically viable route. The fact that 3D printing is their technology of choice strikes a different question with me, however: will Adidas (or any other shoe manufacturer for that matter) still produce shoes? 3D printers are, by definition, extremely flexible and have multiple use cases; if Adidas builds or buys 3D printers capable of producing shoes, these machines would probably also be able to produce multiple other plastic-based products. As a result, in case 3D printing really becomes mature, there will probably be a new economy where we can all just go to “3D print shops” to upload a design of our choice and take the final product with us only minutes later. In such scenario, Adidas’ role would be limited to selling “designs” rather than “shoes”, thereby not only solving inventory and supply chain issues, but eliminating them all together.

Thank you for this interesting article, TOMSupplyChain. FD raises an interesting point. I believe there will always be value in a brand and the expertise that a company like Adidas can bring from a design and performance perspective. I think there are a few ways that Adidas will be protected from becoming just a designer rather than a producer of 3D-printed shoes. For starters, Adidas, as a massive global corporation, will likely be able to better capitalize on economies of scale than more localized printing locations. This will allow Adidas to offer shoes at competitive prices. Additionally, Adidas can emphasize its R&D efforts / understanding of sneaker design to offer high levels of customization. Once 3D technology catches up and becomes faster, I could see an opportunity for Adidas to provide 3D printed shoes with midsoles completely customized to an individual consumer’s needs — such as a softer heel for frequent runners. The consumer data Adidas has collected and its expertise in creating performance-driven shoes could provide a competitive edge as they attempt to create individualized, mass market 3D printed shoes.

Interesting to consider how 3d printing can be applied to mass-production. You brought up some great points about flexibility in design, and reduced shipping / time to market. Another advantage is that 3d printing allows for designs that are not possible to produce with conventional injection molding. This can allow for reduced raw material usage and performance improvements through lighter weight designs.

Although it seems cool from a marketing standpoint, I don’t think putting 3D printers in the store makes sense operationally. First, dis-aggregating production will inevitably cause more variability in demand for an individual machine. This will lower machine utilization overall, and high demand for an individual machine could actually lengthen the throughput time for some orders. I also agree that store employees may not be the candidates for operating the machines. I would recommend that Adidas leverage their store employees to take measurements and drive orders for the shoes, but that they maintain centralized production.

One concern is that I don’t expect they will be able to 3D print the entire shoe. If they still need to source the fabric portion of the shoe from overseas, it seems as though the supply chain benefit is greatly reduced. If Adidas can move to a single material for the entire shoe, perhaps they can overcome this, but that design seems to lend itself only to more niche shoe categories. Another concern I have is that low cycle times will lead to low output and drive up costs. The carbon3D printer that Adidas is currently using costs around $40k per month to lease [1]. From past experience, I estimate it would take around 1 hour to produce a pair of shoe soles. Assuming 30 days in a month and running 24 hours a day, this still means that the machine time would make the COGS for the soles alone $55, and that doesn’t count material costs or labor. Although I expect Adidas can negotiate better pricing with carbon3D, and that technology improvements will drive costs down over time, it is still hard to imagine the costs being attractive compared to injection molding. My recommendation is that Adidas focus on specialty applications where they can reap the full benefits of 3D printing and customers are less price sensitive–such as elite running.

[1] http://www.fabbaloo.com/blog/2016/4/6/tallying-up-the-carbons-total-cost-of-ownership

Thank you, TOMsupplychain! This is very interesting. Regarding the reduction of shipping costs related to 3D printing, it is unclear whether the overall cost of 3D printing including shipping costs for raw materials, such as “3D printer ink,” is lower than the total cost of utilizing traditional manufacturing. The more manufacturing locations are scattered, the higher the total shipping costs could be as there is less scale merit in shipping of raw materials. Similarly, utility costs for production could also increase as each manufacturing location cannot utilize as large-scale merit as does a large centralized production facility. On the other hand, I do not think 3D printing would increase the risk related to cybersecurity for Adidas marginally because the manufacturing system would be more scattered and more independent of each other. If one of the printing facilities goes down, Adidas might be able to use other production facilities to cover up production. Even if the 3D printing production uses a centralized system to manage multiple printing facilities, it is difficult to assume the risk increases because the current centralized manufacturing system should have been exposed to the same cybersecurity risk.