Supply Chain Sustainability at Intel

"Climate change is no longer some far-off problem; it is happening here, it is happening now." -Barack Obama

Intel believes climate change presents a serious threat and is working to address this concern in the short, medium and long term.

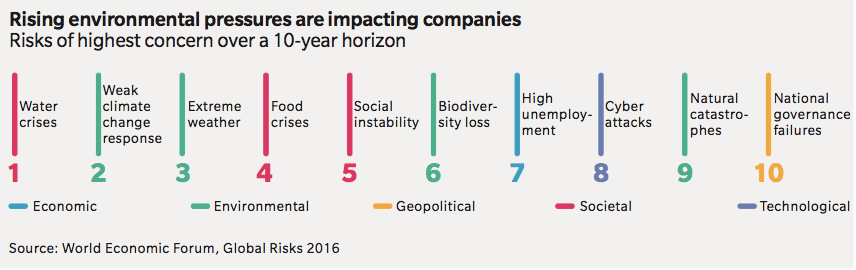

Rising pressures from climate change present an array of strategic and operational risks for companies and their supply chain. According to the World Economic Forum, the environmental risks of highest concern in the next ten years are water shortage, weak climate change response, and extreme weather [1]. In 2016, 40% of filed shareholder resolutions related to environmental and sustainability issues, demonstrating the rising concern of companies related to climate change [2]. In addition to climate-related risks, there is increasing social instability and unemployment. These social trends exasperate the impact of environmental disasters.

Climate change presents unique challenges for companies as decisions made today tie directly to future risks as the impact of climate change is cumulative. Carbon dioxide and other greenhouse gases can stay in the atmosphere for hundreds of years and higher concentrations of these gases lead to increased global temperatures and shifts in weather patterns [3]. However, it is difficult for companies to assess how they should respond to such risks. Two challenges that complicate climate change responses are the sheer magnitude of change required and the inherent “free rider” problem [4]. It is unclear who should help foot the cost the climate change initiatives and if regulatory or market forces should help address the problem.

Intel is a technology company, specializing in semiconductors, with a global footprint and vast supply chain. Semiconductor production requires the use of fluorinated gases, which is frequently targeted in climate change policies and restrictions for its impact on global warming [5]. As such, climate change and supply chain sustainability is a critical risk and concern for Intel. Intel’s management believes global climate change is a serious environmental, economic and social challenge and has set forth efforts and plans to respond accordingly [6]. In the short term, Intel has instituted a Supply Chain Responsibility program, to reduce risks associated with climate change in the supply chain. To support these efforts, Intel has established key performance indicators for environmental sustainability and supply chain responsibility. Metrics include total water withdrawn (billions of gallons), energy use (billion kWh) and greenhouse gas emissions (million metric tonnes of CO2 equivalent).

An additional component of Intel’s efforts is its Program to Accelerate Supplier Sustainability (PASS). PASS includes commitments to compliance, transparency and capability-building. All suppliers are given access to educational resources, including webinars on a range of critical topics. As of 2016, Intel reported participating suppliers represented over 69% of its supply chain spending [7]. As part of PASS, suppliers are asked to participate in a supply chain survey that assesses their climate change risk and opportunities to improve transparency. PASS includes Responsible Mineral Sourcing for Tin, Tantalum, Tungsten and Gold [8]. To ensure these efforts are honestly represented and communicated, Intel completes on-site audits for its 75 top suppliers with assessments on 300 factors. In the next two years, Intel aims to have 90% of its suppliers in PASS meeting advanced expectations. Additional short term goals include 85% “green” Intel ground transportation fleet and continue 100% green power in U.S. operations [9].

In the medium term, management has set corporate goals to further environmental sustainability and supply chain responsibility. Climate change-related goals include [10]:

- Increase alternative energy use for international operations

- Reduce direct greenhouse gas emissions by 10% per unit basis by 2020 from 2010 levels

- Implement an enhanced green chemistry screening and selection process for 100% of new chemical and gases by 2020

- Reduce water use on per unit basis below 2010 level by 2020

In addition, Intel has set a long-term goal to restore 100% of global water use by 2025. To achieve this goal, Intel plans to support local watershed and restore the equivalent amount of water consumed [11].

In evaluating management’s goals in the short and long term, I would recommend management evaluates the overlapping risk profiles of its suppliers. For example, if an earthquake occurred in China, how many suppliers would be impacted by one earthquake? How many suppliers have emergency plans in place to respond to idiosyncratic events and risks? An in-depth analysis of suppliers with similar geographic locations, risks preparedness and percent of total product produced may highlight additional supply chain risks.

A few important questions remain regarding climate change and Intel’s supply chain. As a company, what type of financial and non-financial resources does Intel need to provide to its suppliers to comply with risk mitigation programs? Is the cost of these efforts absorbed by the supplier, Intel, or the customer?

(Word count: 741 words)

[1], [2] Nottingham, Lucy. “Unlock Growth by Integrating Sustainability: How to Overcome the Barrier,” Marsh & McLennan Companies (2016)

[3] Risky Business Project, Risky Business: The Economic Risks of Climate Change in the United States (2014)

[4] Henderson, R. M., et al, Climate Change in 2017: Implications for Business (HBS No. 317-032)

[5], [6] “Global Climate Change Policy Statement”, Intel (2015)

[7], [8], [9], [10] “Intel 2016 Corporate Responsibility Report,” Intel (2017)

[11] Brady, Tom. “Our Commitment to Restore 100% of our Water Use,” Intel (Sept. 19, 2017)

I would argue that an important resource that Intel needs to provide to its suppliers is the ability to gain visibility into their own Tier 1 and Tier 2. When Thailand suffered massive floods in 2011 what most delayed the resumption of production was the lack of OEM visibility into where they had exposure through Tier 2,3 and sometimes 4 suppliers. Without this visibility corrective measures could not be taken and production ground to a halt. In order to reduce this aggregate supply chain fragility, all members require visibility into the participants that they are indirectly exposed to. As a large player in the ecosystem, Intel is well positioned to induce this needed change.

Thanks for this very interesting article!

I think the critical challenge with getting companies to take climate change seriously is the free rider problem you mention. A company like Intel has such a small individual impact on greenhouse gas emissions and overall environmental outcomes, but must incur a high cost (typically) to reduce their impact. What is their incentive to implement programs like the ones you describe?

A cynical answer would be that this is just a PR play. Intel knows that both their customers and shareholders care about climate change, and also likely recognizes that their use of fluorinated gases puts them particularly at risk of being criticized in the media as a bad climate change offender. By enacting and advertising these programs, Intel can control the narrative about whether they as a company are having a positive impact on the environment, and avoid potential criticism from customers and investors.

A less cynical answer would be that there are fundamental business reasons (beyond PR) that make these initiatives sensible for Intel. The PASS initiative in particular could be a good example of this. By getting greater transparency on their suppliers, Intel can better understand which suppliers will be fundamentally threatened by climate change, and be prepared to replace those suppliers if needed.

In all likelihood, their motivations are likely a combination of PR and fundamental business needs. However, regardless of their motivations, it’s great to see a company tackling these important problems.

While I am generally very skeptical of company’s sustainability programs, I am actually less skeptical of Intel than most. The reason for that is their transparency around their stated goals. Their approach follows the SMART principle, which states that goals should be specific, measurable, attainable, realistic and time-bound. These goals seem quite specific and allows customers, suppliers and even competitors to hold them accountable.

Specific goals is a non-financial resource that Intel needed and thankfully did provide to their suppliers. Because it was done in such a public way, suppliers know that Intel is serious about achieving these goals. As such, if they do not partner with Intel to allow them to achieve these goals, it seems credible that they will be willing to change suppliers.

Interesting article, BC. Intel has taken a strong leadership role in addressing its own impact as well as its suppliers’ impact on global climate change. However, two key aspects stood out to me that are worth additional consideration:

1) I agree with Intel’s PASS partnership model between Intel and its suppliers and believe these are critical in ensuring a unified approach towards solving a sustainability issue that will carry through the supply chain. Furthermore, the auditing role is critical as an enforcement mechanism, so both parties can cooperate and don’t operate in “silos” with respect to addressing this issue as well as in creating a measurement system to assess impact. This reminded me of IKEA’s sustainability proposition upstream with its suppliers of certified lumber, where if IKEA works with its suppliers to ensure its criteria are met, they can both work towards sustainability targets. That said, while this investment makes sense for both from a sustainability point, it is harder for me to see the direct and / or immediate positive impact of this on the company’s bottom-line. In other words, why would a shareholder care above and beyond if a customer does not? It is not clear that the customer here, a buyer of its chips, would switch its provider away from Intel in the short-run due to higher usage of flourinated gases (the buyer likely is inelastic in the short-run to the chip they are used to utilizing for the product they are selling). The Intel shareholder would be using profits to further sustainability without reaping direct and immediate business impact. A larger question for society and the government is: Could incentives along the lines of carbon credits trading help provide incentives to create environmental benefit that would impact the bottom line and do so immediately, thereby incentivizing corporates to invest in clean projects and veer away from polluting ones? This would help bridge the social externality present in chip production.

2.) Additionally, a key question of consideration is: What can Intel do further upstream in its energy usage to improve its impact on the environment? For example, Intel has many offices and other infrastructure that are not directly related to the production. Maybe switching to solar panels or other cleaner energy could help offset the emissions they have in chip production. As well, maybe Intel can work with its electricity provider to use more clean energy in its electricity usage in its factory. This would go a step beyond making direct production inputs and processing more sustainable to making it a comprehensive initiative across all organizational elements.