Adidas: Eliminating prototyping and seeking personalization

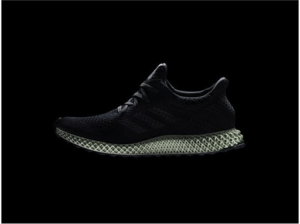

Adidas is using a unique 3D printing technology to explore the world of custom-crafted midsoles designed to enhance performance in running footwear by ensuring comfort and cushioning while maintaining stability and support.

Marrying the qualities of hand crafting and prototyping with the limitless potential of new manufacturing technologies. Futurecraft is stripped back – fast, raw and real – it is our approach to design”

-Paul Gaudio, Global Creative Director of Adidas [1]

3D printing applications have exploded across many different industries and the sports retail industry is no exception. With players such as Adidas, Nike, and New Balance all working to incorporate additive manufacturing into their platforms, will these brands be able to deliver the next level in performance footwear?

The Present Problem

In an industry where performance is critical and the difference between win and lose can be determined in milliseconds, Adidas set off to make the ultimate running shoe for all. [2] The focus – the midsole – which is crucial to the stability, support, and comfort of player’s foot but was limited by a difficult multi-step production process. Midsoles manufacturing required injection and compression molding and relied on assembly through a labor-intensive process. [3] As Adidas sought to provide the best performing shoes for its athletes, they believed 3D printing presented an opportunity to transform this inflexible manufacturing process.

In October 2015, Adidas introduced Futurecraft 3D, featuring a 3D printed midsole, which began the company’s journey to marry technology and process innovation. In April 2017, Adidas released Futurecraft 4D, the next version in the Futurecraft series, presenting high performance footwear featuring midsoles crafted with Digital Light Synthesis (DLS). DLS, a technology pioneered by 3D printing startup, Carbon, uses light and oxygen alongside programmable liquid resins to generate durable polymeric products. [2]

In October 2015, Adidas introduced Futurecraft 3D, featuring a 3D printed midsole, which began the company’s journey to marry technology and process innovation. In April 2017, Adidas released Futurecraft 4D, the next version in the Futurecraft series, presenting high performance footwear featuring midsoles crafted with Digital Light Synthesis (DLS). DLS, a technology pioneered by 3D printing startup, Carbon, uses light and oxygen alongside programmable liquid resins to generate durable polymeric products. [2]

With DLS, Adidas significantly reduced time to market for its products and print previously impossible designs using software. Contrary to the traditional product development process of design,prototyping, tooling, and production, the Adidas-Carbon team could iterate through redesign quickly using the same process and materials as production, thus eliminating the prototyping phase altogether. For example, the Adidas team was able to release Futurecraft 4D only 11 months after partnering with Carbon, a process that typically took 15 to 18 months from design to arrival in stores. [4] Through Carbon’s DLS technology, the midsoles could be printed with zero support material, eliminating the conventional 3D printing post manual steps to remove support and reducing raw material costs. [5]

The Future “Crafted”

Adidas is looking to address the consumer demand for customization and to create a truly bespoke shoe to meet the demand of every kind of athlete. Innovation around the shoe is not enough – Adidas is looking to revolutionize the customer experience – imagine walking into an adidas store, running briefly on a treadmill, and instantly getting a 3D-printed running shoe catered to your footprint. [1] From a production standpoint, the company could shift into more “on-demand” just-in-time production and further reduce excess inventory risk.

By the end of this year, Adidas aims to create over 100,000 of Futurecraft 4D and secure enough printers from Carbon to make one million pairs of 3D printed sneakers. [6] As production scales aggressively, there is opportunity for the economies of scale and technological improvements to lead to a price adjustment as production reaches a critical mass. The first 300 pairs of the Futurecraft 4D were released at $300 and sold out immediately; the shoes now trade at healthy premium price around $1000 according to StockX. [4]

Looking forward, Adidas is faced with a few challenges: 1) fierce competition from their rivals who have made similar investments in additive manufacturing, 2) actualization of customer experience and 3) continued innovation and growth. In the short term, Adidas should focus on scaling their production of midsoles without sacrificing quality, and develop other performance-enhancing products that could utilize the DLS technology. Furthermore, Adidas while growing still faces many competitive dynamics (see Exhibit A below) [7] and should continue to invest in its marketing efforts such as athlete sponsorships, consumer education, and digital platform to develop consistent brand loyalty for its products. Adidas already has an exclusive contract with Carbon, solidifying the partnership, and has collaborated with athletes and organizations to garner feedback for its new product. In the medium term, Adidas could look to invest in machine learning technology to help further optimize the features that determine performance-enhancing shoes. As the company collects data from consumers on running preferences, footprint and sole compatibility, Adidas would have the ability to precisely address the needs around movement, stability, support, and durability across all of its sports lines. As Adidas continues to invest in this new technology, how will they differentiate themselves from their competition and how should they think about integrating their e-commerce platform with their vision for the future customer experience?

http://www.youtube.com/watch?time_continue=66&v=4loUoDD-ex8

Word Count: 768

Bibliography:

[1] “Adidas Breaks the Mold with 3D-Printed Performance Footwear.” Adidas NEWS STREAM, 7 Oct. 2015, https://news.adidas.com/US/Latest-News/adidas-breaks-the-mold-with-3d-printed-performance-footwear/s/8099a318-f9e7-45d8-9887-42c3dde5e6fd.

[2] “Adidas Unveils Industry’s First Application Of Digital Light Synthesis with Futurecraft 4D.” Adidas NEWS STREAM, 7 Apr. 2017, https://news.adidas.com/US/Latest-News/adidas-unveils-industry-s-first-application-of-digital-light-synthesis-with-futurecraft-4d/s/87aae92f-35b2-43a0-8b6c-9162581a440d.

[3] “The Perfect Fit: Carbon + Adidas Collaborate to Upend Athletic Footwear.” Carbon, https://www.carbon3d.com/stories/adidas/. Accessed 13 Nov. 2018.

[4] Cheng, Andria. “How Adidas Plans To Bring 3D Printing To The Masses.” Forbes, https://www.forbes.com/sites/andriacheng/2018/05/22/with-adidas-3d-printing-may-finally-see-its-mass-retail-potential/. Accessed 13 Nov. 2018.

[5] “Watch: Adidas’ New 3D-Printed Shoe Can Be Shaped According to Your Feet.” BusinessInsider, https://www.businessinsider.co.za/how-adidas-and-carbon-made-a-3d-printed-shoe-2018-9. Accessed 13 Nov. 2018.

[6] Adidas Annual Report 2017. https://report.adidas-group.com/#5. Accessed 13 Nov. 2018.

[7] “Infographic: Nike’s Still on Top of the Sneaker World.” Statista Infographics, https://www.statista.com/chart/13470/athletic-footwear-sales/. Accessed 13 Nov. 2018.

The market for high performance athletic products, especially running shoes, is incredibly competitive at the moment. With this Adidas and Carbon partnership, Adidas has the advantage to be the first movers in the space of 3D printing. To be competitive, they need to target the right adopters, and that depends on whether they are after the serious runners or more casual all functioning shoe owners. The former group is a brand-loyal performance-driven group who care primarily about quality. If they are going after the latter group, I think Adidas has more room to operate to make this product a statement of novelty, with their campaign focused on the novel, “cool” aspect of the technology.

I’m impressed about how fast the use of 3D printing in this industry is developing. I agree with Anonymous’ perspective on the need to carefully select the target market. However, I wonder whether they can be successful at either with the much higher price point. The shoe buying experience is still focused on trial before commitment. Beyond the innovator consumers who likely see some novelty value, I think it will take time for consumers to trust that a shoe developed for them will have the right fit and comfort when they actually use it for an extended period of time – and the consumers need to be willing to pay a premium for the shoe.

In my view, the challenge for Adidas is to solve this problem of trial-ability. Perhaps this requires significantly reducing the cost of manufacturing so that they can afford product returns or it might be that Adidas need to have trial archetypes and then apply the 3D printing to customize based on consumer feedback to a the trial.

This is a very cool article about the capabilities that Adidas is building. I think bespoke and customized shoes have great market potential given how quickly the initial prototypes sold out. Personally I really like the design of the new shoes and I believe that additive manufacturing is a great enabler for Adidas to quickly roll out new designs and prototypes. The thing I worry about is how Adidas will keep its competitive advantage. Other companies, especially Nike are also working on the 3D printed shoes and it will be difficult for Adidas to stand out unless it launches first.

Awesome article Rebecca! Very interesting to learn about the development of 3D printing within the athletic footwear space (especially topical given the Nike case).

Putting my manufacturing hat on, the lead time reduction is extremely enticing. However, but production cycle time is a difficult limitation. Compression and Injection molding can take literally a few seconds, but most printing operations take minutes, but typically hours. In this case, Adidas would simply request 1,000’s of machines to build 3D printed soles at a reasonable production rate.

Carbon 3D’s printers are also very slow, expensive, and “finicky” – so that is cause for pause.

Curious to get your thoughts: Do people really need or want mass customization? I remember NikeID – building custom shoes, but then before checking out realizing there were others in production that almost fit my criteria specifically. This is especially an important question because economies of scale don’t really exist in 3D printing. Across the industry, yes, costs come down (slowly). But actually the primary benefit of 3D printing is the low setup-time, despite the super long cycle times. Overall fascinating article – thanks!