Taking a Bite out of Apple: Fighting the Tides of Isolationism

Apple operates one of the most complex supply chains globally and epitomizes the power of globalization – and its pitfalls. Can the re-emerging forces of isolationism derail Apple's success?

On the back of each Apple device, embossed into the pristinely machined surface are the words: “Designed by Apple in California. Assembled in China”. These two deceptively simple sentences shroud the fact that Apple operates one of the most complex supply chains in the world. Today, sporting a market capitalization of nearly $1 trillion[1], the biggest threat Apple faces is arguably not competition from Samsung or Google, but instead is the potent force of isolationism that has emerged both domestically and abroad.

A Bad Apple?

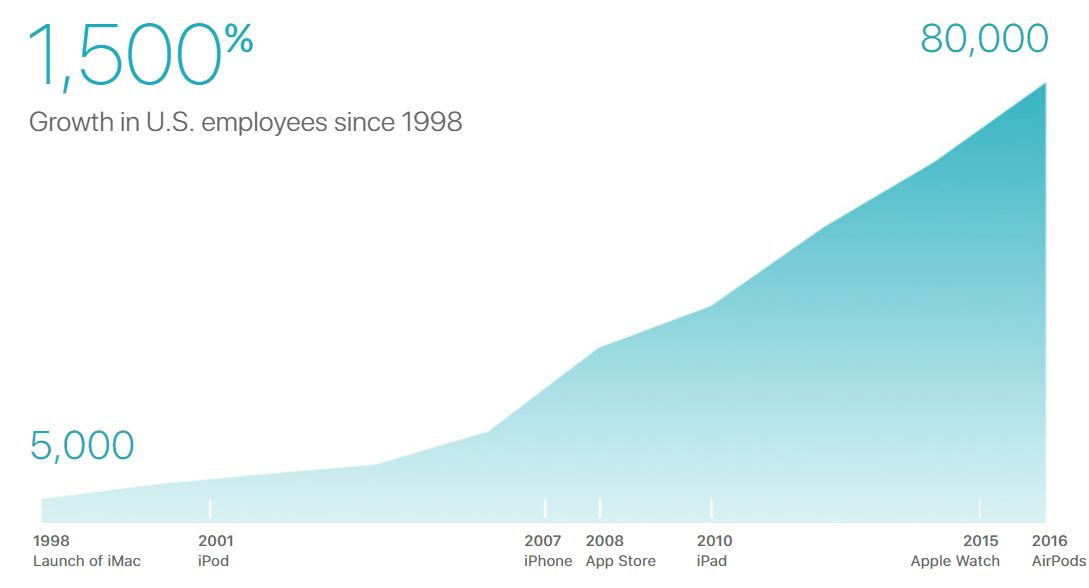

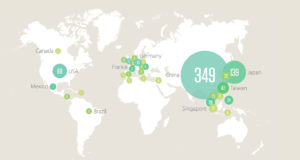

During the 2016 Presidential campaign, Apple became the public whipping boy for globalization. Then-candidate Trump declared, “We’re going to get Apple to start building their damn computers and things in this country instead of other countries”[2]. Trump has a point. The seamlessly assembled iPhone is in reality the amalgamation of components from over 750 suppliers originating from more than 10 countries[3]. The core components that constitute an iPhone are manufactured abroad – displays and batteries from South Korea (ironically, both from Samsung), processors from South Korea (Samsung) and Taiwan (TSMC), cameras from Japan (Sony), all assembled in China (Foxconn)[4]. According to a list of suppliers published by Apple, only 11% Apple’s suppliers were based in the US, while 88% were in Asia[5]. Furthermore, while Apple directly employed approximately 80,000 US employees, a New York Times report estimated that over 700,000 people worked for Apple indirectly in its outsourced Asian supply chain[6]. The behemoth that is Apple’s supply chain rests firmly upon the bedrock of globalization – and isolationist trade policies threaten to unravel it all.

Apple iPhone suppliers by country (2013)

Source: Apple 2013 Supplier Report

Planting a Seed for the Future

Following the election of Trump, Apple CEO Tim Cook took steps to address criticisms directed towards his company. As an immediate step, Apple created a “Job Creation” website that highlighted its job creation track-record[7]. Apple claimed that it has created upwards of 2 million domestic jobs through a combination of Apple direct employees, workers employed by US suppliers, as well as jobs attributable to the “App Store” ecosystem[8]. During the same month, Apple announced that it had established a $1 billion fund that will be invested in US companies that promote advanced manufacturing jobs in the U.S[9]. While $1 billion represents a relatively de minimis commitment by Apple (Apple has $250 billion+ of cash)[10], Apple’s commitment nonetheless represents a tacit acknowledgement that corporations do indeed have a social obligation to weigh actions that maximize profits for shareholders against the potential social impacts those decisions may have.

Apple Direct Employees (1998 – 2016)

Source: Apple Jobs Website

In addition to short-term initiatives, Apple’s management team has also taken steps towards exploring long-term solutions to hedge against potential isolationist policies. In late 2016, Apple reportedly asked two of its largest suppliers, Foxconn and Pegatron, to investigate the possibility of moving iPhone manufacturing and assembly operations to the US[11]. While the ultimate outcome of the feasibility study remains unknown, in July 2017 Foxconn unveiled plans to build a $10 billion LCD display manufacturing facility in Wisconsin that is expected to employ up to 13,000 workers[12]. While these LCD displays are not intended for Apple, Foxconn’s announcement may nonetheless temper the political pressure on Apple, which happens to be Foxconn’s largest customer.

Bridging the Skills Gap

In 2012, Steve Jobs proclaimed that iPhones could never be manufactured in the US – not only because production costs are higher, but also because Apple executives believed that there is a lack of sufficient skilled labor in the US[13]. According to a 2017 World Economic Forum report, nearly one-third of jobs in 2020 will require skills that are not commonly taught today, leading to a widening of the “skills gap”[14]. As the most valuable company in the world, Apple has both the social responsibility and long-term incentives to help bridge that skill gap through investing in education and vocational training. For instance, Apple can help ensure that children today have access to computers and coding curriculums. Apple is in the unique position of being able to harness its vast resources to ensure that consumers can enjoy the benefits of globalization without leaving behind those who are ill-equipped to adapt to the changing technological landscape.

Too little, too late?

The past two decades been among the most rapid periods of economic growth that have ever taken place, driven by the dual engines of globalization and the digital revolution. During that period, globalization has been unquestioningly embraced as corporations outsourced jobs and maximized profits. But at what, and more importantly, whose expense? Is globalization Pandora’s Box? Can the forces that it has unleashed – both good and bad – ever be controlled? And how should corporations like Apple balance the competing objectives of maximizing shareholder profits against fulfilling their social obligations? Chances are, even Siri will struggle to find the right answers.

Word Count: 799

Footnotes:

[1] Market capitalization of $868 billion as of November 15th, 2007 (Capital IQ)

[2] “Donald Trump’s Fight With Apple Is Risky | Money.” Time, Time, time.com/money/4232235/apple-donald-trump-boycott/.

[3] “Apple Supplier Report: 88% Are in Asia, 44% in China, 11% in America.” VentureBeat, 17 Feb. 2013, venturebeat.com/2013/02/17/apple-supplier-report-88-are-in-asia-44-in-china-11-are-in-america/.

[4] Ibid.

[5] Ibid.

[6] Bradsher, Charles Duhigg and Keith. “Apple, America and a Squeezed Middle Class.” The New York Times, The New York Times, 21 Jan. 2012, www.nytimes.com/2012/01/22/business/apple-america-and-a-squeezed-middle-class.html?pagewanted=all.

[7] https://www.apple.com/job-creation/

[8] Ibid.

[9] Nellis, Stephen. “Apple to Create $1 Billion U.S. Advanced Manufacturing Fund.” Reuters, 3 May 2017, www.reuters.com/article/us-apple-fund/apple-to-create-1-billion-u-s-advanced-manufacturing-fund-idUSKBN17Z2PI.

[10] Apple Inc. (NYSE: AAPL) September 2017 Annual Report

[11] Wu, Debby. “Apple Could Make IPhones in US in Future: Sources.” Nikkei Asian Review, 18 Nov. 2016, asia.nikkei.com/Business/AC/Apple-could-make-iPhones-in-US-in-future-sources.

[12] Mickle, Tripp. “Foxconn to Build $10 Billion Factory in U.S.” Wall Street Journal, 26 July 2017, www.wsj.com/articles/apple-supplier-foxconn-to-build-10-billion-factory-in-u-s-1501102903.

[13] Bradsher, Charles Duhigg and Keith. “Apple, America and a Squeezed Middle Class.” The New York Times, The New York Times, 21 Jan. 2012, www.nytimes.com/2012/01/22/business/apple-america-and-a-squeezed-middle-class.html?pagewanted=all.

[14] World Economic Forum. http://reports.weforum.org/future-of-jobs-2016/skills-stability/

This is a really critical issue that you have touched on – not just for advanced economies, but for developing economies alike. Given the slew of new industries that have given rise to new skillsets that employers are looking for, economies need to find ways to develop talent internally, especially under a paradigm of isolationism. I agree that Apple cannot sit back idly and wait for the education systems to reform to compensate for the new skillsets. However, I am worried about a world in which Apple runs education. Not only does this give them a monopolistic competitive edge over new generations compared to their competitors, but it also gives Apple control over the ideas that entire generations are founded on. Corporations like Apple should definitely not be competing in classrooms while attempting to develop crucial skillsets. Thus, I think the government needs to play an important role here in forming partnerships with corporations like Apple so that all players can work together towards the goal of skills development. The competitors have to put their “business” outside the classroom in order for our society to raise an unbiased youth.

https://d3.harvard.edu/platform-rctom/submission/taking-a-bite-out-of-apple-fighting-the-tides-of-isolationism/?section=7752&sort=rand

I wanted to thank you, Chris, for making the point that “apple has both the social responsibility and long-term incentives to help bridges that skill gap through investing in education and vocational training. Many of Apple’s competitors understand and accept this responsibility. Dell is a great example of this: through a partnership with Girls Who Code, the company has committed strengthening and expanding after-school programs in computer science education for an estimate 15,000 girls in grade 6-12 across the US through a combination of financial, technical and mentorship support. This serves as a perfect example of what you described which is it is very possible for a company to do good while it does well. What is most jarring is that Apple executives explicitly believe that there is a lack of sufficient skilled labor in the United States. You asked a very powerful question: “at what, and more importantly, whose expense?” Instead of making a decision to improve the landscape, educate people domestically (many of which who will never be given such opportunities) and create jobs in the states, they inconsiderately decided to maximized profits in the short term. I’m not sure companies like Apple will ever change. I believe it is the responsibility of consumers to not buy the products of companies that fail to accept their corporate social responsibilities.

http://www.dell.com/learn/us/en/uscorp1/press-releases/2016-10-11-dell-expands-investment-in-girls-computer-science

Chris, thanks for highlighting a critically important issue for consumers and corporations like Apple alike. I disagree with HBS Rules’ comment above that Apple “inconsiderately decided to maximize profits in the short term” by failing to educate domestic workers. As Shrkatck noted, as a public corporation that answers to its shareholders, it’s really not Apple’s role to invest in domestic education – this, I’d argue, is one of government’s most important functions.

As Chris explained, Apple indirectly employs over 700,000 people through its outsourced Asian supply chain. As an American company, does Apple actually owe more to American workers than it does to workers abroad? And how should Apple weigh the benefits it could provide to American workers by manufacturing more iPhone components domestically against the very real value the company provides to consumers worldwide by making an incredible device available for just a few hundred bucks? I don’t pretend to have the answers to these questions, but I find it a bit simplistic to blame Apple for using globalization to its advantage to make iPhones more affordable for the masses.

This is a very complex topic Chris and I am glad that you selected it because I am sure it will open up for an interesting discussion. In the last few years, we’ve seen how policies have augmented the uncertainty of several industries that leverage international trade to do business while others have reported hundreds if not thousands lost jobs (https://goo.gl/ne8X2y).

The complex supply chain that Apple handles and involves almost a dozen of countries is a reminder that specialized talent and skills are spread all over the world. As such, corporations and countries alike must adapt and evolve at a fast pace or perish in the process. I see how the government is pressuring large multinational corporations to bring back jobs to the country and how new legislations could go against innovation and the companies’ growth.

Apple is without a doubt one of the largest contributors to the US economy and as such is held accountable on many fronts, from sustainability to corporate responsibility and even diversity and inclusion in Tech. However, I strongly believe that the public, in general, should not expect the private sector to do the job that the government is supposed to do using the resources collected from tariffs. Several public figures have pushed for a more diverse workforce in the tech industry but never held accountable the tech titans like Apple or Google (https://goo.gl/QoPLES). In fact, Apple millions of customers in every continent and I even question if it remains an American company to become a globalize enterprise (the reason why they have billions parked in the tax haven such as Dublin in Ireland).

I encourage and applaud Apple internal initiatives to create a more diverse workforce, to propel computer science education in high schools or even to employ as many people as possible in the US while paying fair salaries but I don’t think we should hold this company, or any, accountable for what the government has fallen short to provide or blame the sophisticated and streamlined supply chain in Asia as they never attributed their underdevelopment to foreign companies, instead they evolved and reached a superiority of economies of scale that we positively envy these days.

I totally agree with Mike’s point of view. Apple, as all big corporations, do have to accept the social responsibility, but the question is whether that responsibility is merely to the US or to the entire world. For the last several years, Apple revenues from the US market is actually shrinking relative to other regions – as a matter of fact, China is the one market which was key to Apple’s ever increasing sales and revenues.

The second question is whether Apple can actually sustain the existing count of US-based jobs and all the salaries associated with those if it wasn’t for the high profits generated by the existing ‘low cost’ Asian supply chain. Because otherwise, Apple has to accept lower margins, and I am confident that the consumers are not willing to absorb the higher price tags for the same products if Apple were to change its supply chain. That’s another question which I do not have the answer for either.

Thanks for the post Chris. I can’t help but feel skeptical about companies such as Foxconn opening a manufacturing facility in the U.S. – though there are significant (potentially short term) benefits to the local economies of say Wisconsin, I fear that such moves were motivated by political decisions than business decisions. In the long run, I fear that non-US companies, in order to appease the new administration may build ‘token’ factories across the U.S. but lack the motivation to invest in its people in these facilities. Though an extreme viewpoint, I can’t help but wonder if opening factories is the new form of gift giving.

This is a really interesting debate on the role of social responsibility in a private company. Walmart is an example of a company that, for the last few years, has committed to sourcing a certain amount of products made in the US as part of their effort to boost the US manufacturing industry. Like everyone mentioned, I don’t think there’s a clear cut right answer. There are trade-offs involved with single-mindedly pursuing profit maximization, and there are also trade-offs involved with prioritizing social responsibility at the expense of profit maximization. I agree with Mike above that it’s not the job of private corporations like Apple to solve America’s workforce education problems. While forcing companies to bring jobs back to the US might help the American economy in the short term, it doesn’t address the underlying problems with how America’s workforce is currently being educated that are contributing to the skills gap. That’s ultimately for the government to work on resolving.

Interesting post! I always find the timelines of this extremely interesting, which you’ve touched on in your essay. While Foxcon is potentially building this new facility, how long will it take to build? How long will it take to employ enough people with the skills to do the job or train them? It’s likely not within the timeframe of Trump’s first term, so it would be interesting to see what would happen with Apple and these other companies if they were able to pass isolationist legislation by 2020. Let’s hope Congress continues to be slow or we’ll end up with extremely expensive future iPhones…

Chris, thank you for the post. I may be looking at this from a completely different angle, but in my opinion, isolationism is often originated from the label that the general public places on each company, and in Apple’s case, the fact that Trump (and probably most people in the world) considers Apple to be a U.S. company is one of the root causes of the issues mentioned above.

Given the ongoing globalization in every aspect of business, I wonder the concept of placing such label to companies would still make sense. As you and Mohamad mentioned, most of the components are produced in Asia, and later sold in Asia. As for now, Apple is still mostly owned by U.S. person and funds, but with the economic development of rest of the world, it is possible to have the majority owned by non-U.S. shareholders in the future. In that case, we would only call Apple an U.S. company based on where its founded, and where the current HQ is…would these reasoning remain to be logical for Trump to declare such statement, or for Apple to “return” to U.S.?

I believe globalization is an irresistible trend, and Apple will further de-Americanized in the future; it makes me wonder, if concept of isolationism will completely disappear and general public would think it is the common property of the world, or there will be stronger resistance from the isolationists.

Thanks for the insightful post, Chris.

I can’t help but think if the isolationist policies mentioned above will lead to adverse effects on U.S. companies. For example, by demanding iPhones be produced in the U.S., what if the price of an iPhone drastically increases and becomes price noncompetitive with foreign competition? I am afraid these second-order implications are not fully contemplated when discussing “bring jobs back home” agendas and may ultimately cause more harm than good in the long run. Others who have examined this issue found the retail price of an iPhone would jump to around $2,000 if exclusively produced in the U.S. (https://www.marketplace.org/2014/05/20/business/ive-always-wondered/how-much-would-all-american-iphone-cost) and that analysis is a few years old, indicating the price in today’s dollars could even be higher. It will be interesting to see if and how isolationist policies are enacted and the ripple effects on the economy.

Chris – what a great article to highlight the challenges posted not only by isolationism, but also the resulting skills gap. I thought your comment, “As the most valuable company in the world, Apple has both the social responsibility and long-term incentives to help bridge that skill gap through investing in education and vocational training,” was particularly insightful. Do you believe that Apple has this responsibility because it is the most valuable company in the world or because it is arguably one of the biggest contributors to the skills gap? Is any company that contributes to the skills gap responsible for investing in education and vocational training? How much responsibility does the U.S. government bear, and should it be incumbent upon the government to take the lead? I personally believe that this is one of the largest challenges facing the global economy today and that the answers to these questions will determine how successful we are as a society moving forward.

Chris – Thank you for writing such a thoughtful article that has provoked so much thought and discussion. I’ve enjoyed reading everyone’s comments as much as I have enjoyed reading the article so I’m going to use this as an opportunity to add my own thoughts to a couple of people’s comments…

1. Re: George’s comment – I like how you ask how much responsibility does the U.S. government bear in education and vocational training, and should it be incumbent upon the government to take the lead. I would add the question though of how much responsibility the U.S. Federal government bears here, and whether vocational training should be something that is more top of mind for the states (e.g. through community colleges, etc.)

2. Re: Coffee Lover – Very interesting comments! I wonder why we still label companies by their nationalities though even though you suggest it may be an ineffective thing to do. Even though globalization is likely irresistible as you suggest, our continued desire to label by nationality may suggest there is inherent value in having a sense of national identity. What I am bothered by more with respect to Trump’s comments about Apple is why the “Designed in America” label is not enough. Even though iPhones are not produced here for economic reasons, I think the fact that much of the innovation and design is done here is great and something Americans can take pride in.

3. Re: Mike’s comments – I love the way you have asked about who Apple is responsible to, be it American consumers, American workers, or should it even have a greater responsibility to Americans at all. I don’t claim to have answers either, but I don’t think there is enough public dialogue around the benefits of globalization to American consumers (who are also American workers). Perhaps more conversation around this could start to change the tides of isolationism.

Chris, you touch on a great point when you mention the skill gap. On this topic, a provocation: even if we could bring the production of the iPhone to the US without increasing costs that much, is that what’s better for society? Wouldn’t everyone be better off leaving the manual manufacturing work to developing countries that can perform it more efficiently and invest instead in empowering Americans to tackle the higher value-added jobs, particularly in technology?

Chris – I loved reading this, thanks so much for your research. Two items in particular that I found most interesting:

1) That Apple would choose to create a $1B fund to invest in OTHER U.S. companies that invest in manufacturing jobs in the U.S. This frankly seems silly to me. While I understand this is a lower barrier to entry for them in terms of bringing manufacturing jobs to the U.S. as compared to investing in their own infrastructure, I frankly would rather see Apple themselves continue to drive for optimizing domestic opportunities.

2) I complete agree with your sentiment that Apple has the responsibility to invest in vocational and educational training, and that they are in a unique position to be a leader in doing so.

Chris, really great post! It’s interesting how after many decades of US companies outsourcing production to developed markets and maintaining an open trade economy the trend seems to be reversing. Coming from a country that has tried very severy isolationism policies in the 1970-80s I believe that this always comes at a high cost. In open and efficient markets production is allocated to those countries who have a cost advantage in the development products or services. Moving production of the iPhone and other Apple products to the US would not only face a performance gap (which I believe can be breached with some effort) but it will very possibly face higher costs.

Producing Apple products while maintaining the same level of quality would imply higher labor costs as well as huge investments to expand production capacity in the US. While in the short term, this can bring money into the US economy, there are several drawbacks. First, Apple (which faces intense competition) would be at a disadvantage with other players like Samsung. Higher costs of production can have a huge impact on what is today the 2nd biggest company in the world (by market cap). If the US government decided to restrict imports, so that Apple wouldn’t have to compete with international players, this would lead to higher consumer prices in the US and potentially similar restrictions for other US companies abroad.

Even if isolationism can indeed bring back manufacturing jobs to the US, its overall impact can be very negative. At the end of the day, someone has to bear the cost of the reduction in efficiency caused by these policies. In 1970-80s in Peru (although policies were much more aggressive than what we are seeing in the US today) this led to a very inefficient manufacturing industry that provided low-quality products at very high prices for consumers. In this case, ultimately consumers ended up bearing the cost of these policies. When the economy was opened up in the 1990s many of these inefficient companies went bankrupt due to international competition. Ultimately more jobs and economic prosperity was generated by focusing on industries in which Peru was competitive. Let’s hope that the wide range of examples of the negative effects of these policies are being taken into account in new legislation.

This is a really insightful article, Chris! The issue of social responsibility vs profitability is complex but I agree with Mohamad’s comment that for an organization of this magnitude that is truly global, social responsibility should transcend the entire world as well.

I can offer the Indian context and example. India is the world’s second largest smartphone market growing at a healthy rate of 20%, but Apple has not been able to capture more than even 3% market share. This is primarily because of very high prices due to India’s protectionism laws that put heavy import duty on iphones and prevented apple from opening retail stores, forcing it to tie with resellers and thus increasing cost-to-serve to Indian market by 15% to 20%. These checks apply to Apple because it doesn’t source or manufacture any parts from India. Even though these might be labeled as protectionist measure, in this case, the role of the government is crucial as it is preventing drainage of wealth from the country specially when the economic and social environment of the nation doesn’t benefit from a foreign company looking to capture the market.

Governments, therefore do have an active responsibility to work with corporates and balance both stakeholder value and social prosperity. From the company’s perspective, if it calls itself a global firm, it needs to adopt a truly global perspective about value creation too.

Chris, Thank you so much for your thoughtful post–as you can see above, it’s really driven some interesting commentary.

I feel particularly torn on the issue that is being debated in the comments–briefly, what obligation Apple has to the US in order to ensure there isn’t a skills gap. While I am 100% for creating a strategy that both creates value for stakeholders/shareholders AND positively impacts social concerns, I think I fall in the camp that this is more of a governmental issue than Apple’s responsibility. The press consistently talks about “job creation” as one of the key tenets of the government’s duty–I think it falls on that entity to provide the opportunities to keep a particular community competitive than it is for the company itself to do that. New, innovative companies create a market for skilled and unskilled labor that communities then respond to and participate in; while I do think Apple should be spending its money thoughtfully in the communities in which it operates, I don’t think it holds the lion’s share of the duty for creating them in certain countries or regions.

Chris, I have to take exception to your contention that a “skills gap” has much, if anything, to do with the state of Apple’s supply chain. The iPhone has only a few major components of any significant value – analog and digital integrated circuits (which must be designed and manufactured), and the screen.

Most of the integrated circuits are designed by American semiconductor engineers such as Qualcomm, Intel, Broadcom, and Apple’s internal design team. America is certainly not lacking premier design talent — in fact, a wave of consolidation has reduced headcount. Most IC manufacturing (by dollar value) is performed in the United States, Taiwan (by TSMC), and in Israel (at Intel’s fab there). While TSMC has seen growth of its market share, its success has not been driven by lack of talent at US competitors but by relatively low wages and innovative operating models.

Similarly, the success Korean firms have seen in LCD and OLED manufacturing has not resulted from winning a war on talent, but by investment in R&D and manufacturing scale, and the ability of the Korean conglomerates to suffer very low margins in the space.

So what do global partners in Apple’s supply chain do? Low skill, low value-add, labor-intensive assembly operations.

Ultimately, I see Steve Jobs’s complaint as an essentially baseless excuse, and not a serious criticism of our skill pipeline.

Great Article Chris. Clearly there are a number of obvious benefits to globalization (lower costs, ability to leverage country expertise, etc.) but its interesting to consider the longer term impact of exploiting those benefits. In this case, you site a larger gap of expertise development and education as well as domestic job loss. I would personally challenge the notion that it’s a companies responsibility to address these issues entirely, even if they are the largest.

Instead, I see these issues as the one of the major roles of government and regulatory bodies. Outside of the reality of how the US government and corporations influence each other, I would argue that government mandates should work to address the undesirable impacts of globalization in a way that doesn’t necessarily impact the current organizational operations. An example of this might be an education tax on apple that would go to other companies or institutions better aligned to educate America’s youth as opposed to having Apple vertically integrated to a point of ineffectiveness.

Great article, Chris. I had no clue that in three years, people will need skills that are not commonly taught today to get jobs. That’s striking! You are so right that Apple is in this very unique position to help train tomorrow’s workforce just because of the company’s sheer size. I would hope that Apple is willing to be a more responsible citizen of the societies it operates in.

One way to help the negative impacts of globalization is for the governments to step in and relieve some of the tax constraints associated with manufacturing as well as the transportation constraints and costs associated with moving manufactured parts across the U.S.

Secondly, as technology continues to develop, less human interaction will be needed to manufacture these parts. The labor costs will decrease with the use of machines and robots. This will slowly bring the manufacturing processes back into the U.S.

Chris, thank you for opening up such an important debate on the role of private companies through the lens of Apple. I agree with Kamau that many of the issues you have raised are outside of the scope or control of Apple as a private corporation, and they fall under the purview of government or regulatory bodies. One interesting area Apple could consider is intensifying its regulatory efforts, to fully educate the government on the challenges and costs of shifting more operations and employment to the US. Their operations and supply chain are exceptionally complex and reducing the information assymetry might help to align expectations on what levers can be pulled, at what cost.

Thanks Chris, this is a very interesting article. It is very interesting to read about your mentioning of the perceived skills gap in American workers. Based on my experience working and studying in Asia, I know that the Chinese government is heavily funding the training of Chinese engineers and other technical professions at the university level. Chinese universities graduates many multiples of engineers or STEM trained graduates as compared to U.S. universities. Therefore, it is not surprising to me at all that there is a perception that Asia has a much higher available pool of technical talent. If the United States seeks to remain competitive in the technology / manufacturing space, it is vital that the U.S. government similarly invests behind technical training as the Chinese government does.

Chris, thanks for the great article on Apply. I’ve been a loyal customer of Apply since college, and have a collection of almost all the Apply iPhone, iPod, iPad, Macbook and Watch products over the past several years. While I do understand that the Trump government wants Apple to make greater contributions domestically by creating more job opportunities to the U.S. labor force, I think it a mission impossible given the nature of the telecommunications devices industry – to minimize costs and maximize profits it only makes sense for a company to spread its production and supply chain across a number of countries, particularly those in the emerging markets given their lower labor and production costs. Also, there will be more complicated impact from shifting production and shipping back to the US. One question that will inevitably arise is – how will countries like China where lots of iPhone manufacturing and assembly take place respond to the shift? Exiting China would not only mean an elimination of hundreds of jobs to the Chinese labor market, but would also possibly engender actions from the Chinese government such as restrictions on goods imported from the US.