Devon Energy: Big Data Meets Oil & Gas

Devon Energy, an independent US Oil & Gas company, is leveraging data analytics to improve efficiency and lower cost throughout its operations in order to gain a competitive advantage in a commodity business.

Exploration and Production: Devon Energy

The Oil & Gas industry, while inextricably linked to physical equipment and capital expenditures, stands to gain a great deal from greater use of data and analytics. One company at the forefront of this transition is Devon Energy, one America’s largest independent Oil & Gas companies (read: not ExxonMobil, Shell, etc.). Within its Exploration & Production operation, which is responsible for locating petroleum reserves, extracting them, and delivering them to trucks and pipelines for transport and refinement, Devon is relying on data to bring efficiency to what has historically been as much an art as a science.

Devon Well Construction Center (Source: American Oil and Gas Reporter)

Efficiency Through Data

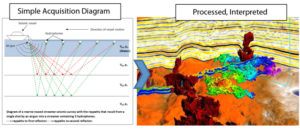

Devon has instituted a number of data-driven initiatives throughout the E&P stages of reserve discovery, drilling, and extraction. On the discovery side, Devon is bringing data analytics to the geological data generated by survey techniques, such as ground-penetrating radar. By comparing survey results with prior data, Devon can more confidently determine the quantity of underground reserves in a given location.[1] It is a job today that is largely driven by scientists and engineers, and still has a great deal of error.[2]

Seismic data acquisition diagram and interpreted 3D model (source: Analytics Magazine)

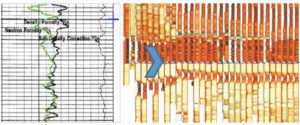

When it comes to drilling wells, Devon is able to use sensors on drill bits and rigs to more accurately track bit locations and progress in real time, allowing for much more accurate and safer drilling, with less equipment breakdowns.[3] And finally, when it comes to extraction, Devon leverages data to perform predictive maintenance on wells,[4] predictive analytics to better decide which non-performing wells should be re-fracked (essentially renewed)[5] and to track the quantity of reserves remaining across its portfolio of more than 100,000 wells.[6]

Raw and processed well imaging data (source: Analytics Magazine)

The result of all this has been huge. Devon has seen a 250% increase in 90-day production volumes since it first began experimenting with data in 2012, the highest in the US on-shore market.[7] Additionally, it has seen its cost per well fall 40% over the same period.[8] While some competitors are also using data, Devon is far ahead of most independent US E&P companies. Bain estimates that only 4% of executives across industries are capable of analytical leadership, and that while some Oil & Gas companies have begun making data investments, many have struggled to effectively implement data-driven techniques.[9]

Challenges, Past and Present

It has been a challenging path for Devon as well. One challenge is related to the nature of the data. Data generation is inherently expensive, as much of it can only be generated during drilling operations. Furthermore, when it comes to geological data, wide variances in locational characteristics and lack of volume make it difficult to generate the requisite data volume necessary to generate meaningful insights.[10] Testing is difficult too, given that it goes along with huge expenses in actual drilling operations, which poses a challenge compared to A/B testing on an online platform with millions of transactions.

There are organizational challenges for Devon as well. The team originally set up to implement this data-driven approach at Devon needed to get buy-in from the engineers whose routines they were affecting. One early comment received was “if it doesn’t help us extract oil and gas from the ground, so what?”[11] The team embraced this criteria and has focused on working closely with engineers and adopting a hypothesis-driven approach to avoid screening data for its own sake. The team is also acutely aware that engineers and scientists have learned to interpret data and signals over years of experience, and it is important that the data capture and support that learning while trying to improve performance at the same time.[12]

Scope is important; the team has implemented IT solutions centered on Hadoop and other technology to streamline data analysis, and to leverage natural language processing and machine learning to pull in new sources of data and improve insight generation.[13]

While the initiative has been successful so far, there are clear challenges on the horizon. One challenge is to continue to increase the ability to test cheaply and generate increasing volumes of relevant data in a scalable manner, especially relevant given the nature of Devon’s operations.[14] At the same time, Devon is operating in a cyclical business tied to commodity prices; cost advantages give them a huge leg up against competition, but Devon must continue to be able to invest across the business cycle. Lastly, as competitors catch up in terms of IT capabilities and sophistication, Devon must continually push to maintain its advantage.

[1] http://www.aogr.com/magazine/cover-story/analytics-dedicated-centers-enable-real-time-optimization-of-devon-energys

[2] http://analytics-magazine.org/how-big-data-is-changing-the-oil-a-gas-industry/

[3] http://www.spe.org/news/article/devon-energy-rises-to-the-top-as-a-data-driven-producer

[4] http://www.rigzone.com/news/oil_gas/a/130590/The_Big_Challenges_of_Big_Data_for_Oil_Gas/?all=HG2

[5] http://www.aogr.com/magazine/cover-story/analytics-dedicated-centers-enable-real-time-optimization-of-devon-energys

[6] http://www.spe.org/news/article/devon-energy-rises-to-the-top-as-a-data-driven-producer

[7] Ibid.

[8] Ibid.

[9] http://www.bain.com/publications/articles/big-data-analytics-in-oil-and-gas.aspx

[10] http://analytics-magazine.org/how-big-data-is-changing-the-oil-a-gas-industry/

[11] http://www.spe.org/news/article/devon-energy-rises-to-the-top-as-a-data-driven-producer

[12] http://www.aogr.com/magazine/cover-story/analytics-dedicated-centers-enable-real-time-optimization-of-devon-energys

[13] http://www.oscar-energy.com/big-data-internet-of-things-transforming-oil-and-gas-operations

[14] http://analytics-magazine.org/how-big-data-is-changing-the-oil-a-gas-industry/

Great post Will. What do you think is the role for service providers here? Should E&P companies develop this capabilities in-house or should the Halliburton’s of the world strive to create more value-added products?