Will your next running shoe be 3D-printed?

Imagine walking into a store, scanning your foot, and receiving a custom tailored running shoe on the same day. Under Armour is turning this vision into reality by leveraging 3D-printing to disrupt the 100-year old cut-and-make footwear manufacturing model.

CONTEXT

Before we take a look at how Under Armour is reinventing its supply chain by adopting digital technologies, it’s important to note a few facts –

- In even the most advanced footwear manufacturing facility, ~150-200 people touch a pair of shoes as it moves down the production line [1]

- On average, a running shoe is manufactured using 55 different pieces [2]

- In the traditional manufacturing model, it takes about 12-14 months to move from ideation to full production for running shoes [1]

The apparel and footwear industry has not seen much innovation around its manufacturing processes in the last century. However, the emergence and adoption of technologies such as 3D-printing, scanning, and imaging are changing the way Nike, Adidas, New Balance, and Under Armour design shoes. These technologies are essentially disrupting the footwear design and production process by enabling customization and reducing lead times and time in transit. [3]

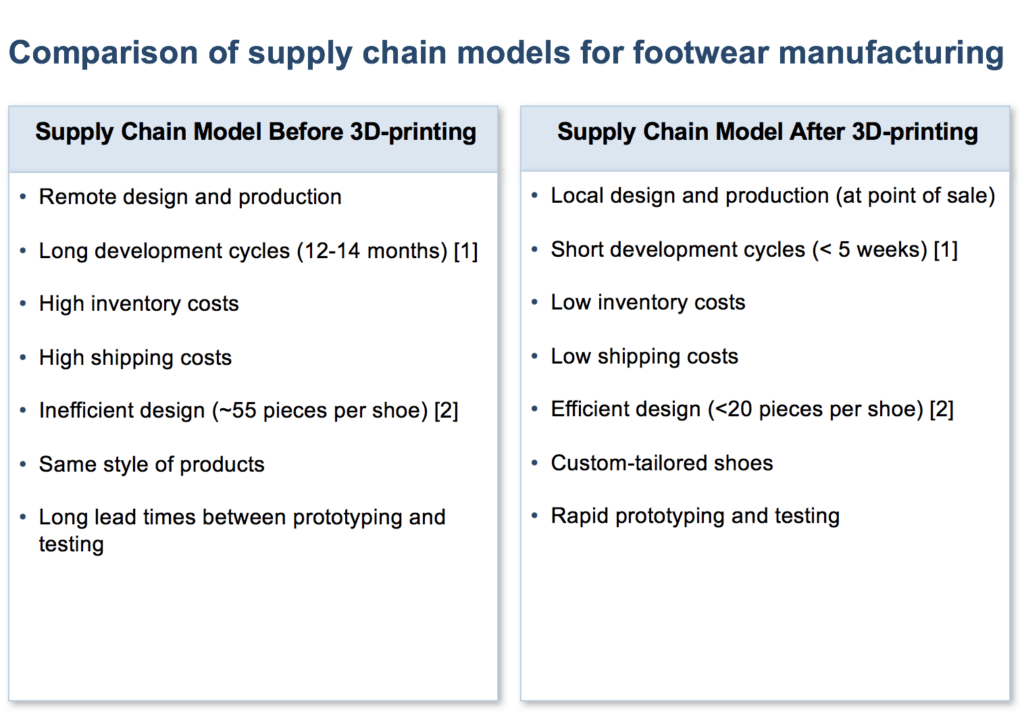

Figure 1 below provides a snapshot of the supply chain model before and after the introduction of 3D-printing.

Figure 1 – How 3D-Printing is disrupting footwear manufacturing

OPERATING MODEL CHANGES

Previous model

Prior to 2015, Under Armour’s footwear and apparel were produced by 29 different manufacturers across 14 countries, with 65% of products made in China, Jordan, Vietnam, and Indonesia. [4] With rising labor and energy costs in China and other developing markets, complications with international shipping, and significant advancements in manufacturing technology (e.g., robotics, automation, 3D-printing), Under Armour began to reevaluate the 100-year old manufacturing model.

New model

“To develop and discover ways to use advanced manufacturing processes to make products on a smaller scale in local markets while improving products’ performance.” [4]

To achieve the above goal, Under Armour launched the “local-for-local” manufacturing model, helping manufacture products closer to the markets where they are sold.

How is Under Armour implementing this new model?

Earlier this year, Under Armour unveiled the UA Lighthouse, its new center for manufacturing and design innovation in Baltimore. The center will focus on developing cutting-edge manufacturing processes and leveraging advanced technologies to design high-quality products locally with minimal amounts of raw materials.

Specifically, this new innovation center in Baltimore has –

- 3D Design and Body Scanning – Takes volumetric body scans and outputs specifications for designing custom footwear and apparel.

- 3D Printing and Prototyping – Five-axis machining center with fabrication tools that help convert scans and ideas into tangible products.

- Apparel and Footwear Prototyping – Area within the center where designers and engineers will collaborate to design products and processes in ways beyond the traditional cut-and-make methods.

- Apparel and Footwear Pilot Lines – Proving ground for manufacturing processes and concepts to see how they’ll perform in full-scale production environments. [6]

Here’s a video that provides a sneak peek into the UA Lighthouse:

And here’s a video showcasing Under Armour’s first 3D-printed shoe (UA Architech). [5]

Potential impact of Under Armour’s new operating model

Benefits to Under Armour:

- On-demand manufacturing – Imagine walking into an Under Armour store, scanning your foot, and receiving a custom shoe within a few hours. That creates significant customer value, reduces time-to-market by removing intermediaries, eliminates shipping costs, and simplifies inventory management.

- Waste reduction – The new processes and technologies are already helping Under Armour reduce wastage and raw material costs. Their SpeedForm shoe is manufactured using 14 pieces versus the industry average of 55 pieces per running shoe. [2]

- Increased agility – The biggest drawback of the traditional model is that by the time retail stores receive the products (~15 months after ideation), the styles may be out of style. In a recent interview, Randy Harward, Senior VP of Advanced Materials and Manufacturing at Under Armour, said: “You’ll still have some things taking 12 to 14 months, but you’ll have 30 to 50 percent of your product made within three weeks.” [1]

- Creation of local jobs – By deploying the local-for-local manufacturing model, Under Armour is essentially “onshoring” jobs.

Looking to the future, Under Armour will need to take actions to address the following:

- Consumer perception – Large majority of consumers still perceive 3D-printing products to be a hype or marketing gimmick. Under Armour will need to spend a significant amount of time to educate consumers about the performance of 3D-printed shoes and apparel.

- Economies of scale – While 3D-printing significantly compresses the supply chain, the costs of proprietary raw materials (usually sold at high profit margins) are high. Under Armour will need to work with their raw material partners to drive down costs. [8]

- Intellectual property – 3D-printing is expected to grow by 330% between 2012 and 2020 with a 48% adoption rate across manufacturing companies [9]. With such high adoption, anyone with the 3D scan can produce an Under Armour designed shoe.

- Hiring skilled workforce – As new technologies disrupt the traditional cut-and-make model, Under Armour will need to invest in upskilling existing and potential employees by providing training for operating new technologies (3D-scanning, 3D-printing, etc.).

Word Count: 798 words

Sources

[1] Monroe, R. (2016, June 28). Under Armour’s quest to Dethrone Nike and jump-start Baltimore, Bloomberg, http://www.bloomberg.com/features/2016-under-armour-kevin-plank/, accessed November 17, 2016.

[2]Sharrow, R. (2016, June 28). Kevin Plank: Under Armour’s new city garage innovation center will help spur manufacturing, Baltimore Business Journal, http://www.bizjournals.com/baltimore/news/2016/06/28/kevin-plankunder-armours-new-city-garage.html, accessed November 17, 2016.

[3] Schoffer, F. (2016, April 24). The race for the first 3D printed shoe, Venture Beat, http://venturebeat.com/2016/04/24/the-race-for-the-first-3d-printed-shoe/, accessed November 17, 2016.

[4] Mirabella, L. (2015, October 10). Under Armour’s vision for future manufacturing: Make local for local, The Baltimore Sun, http://www.baltimoresun.com/business/bs-bz-under-armour-local-manufacturing-20151010-story.html, accessed November 17, 2016.

[5] The 3D-Printed athletic shoe race and what it means for your retail based supply chain. (2016, April 17), PR Logistics Corp, http://prlogistics.com/the-3d-printed-athletic-shoe-race-and-what-it-means-for-your-retail-based-supply-chain/, accessed November 17, 2016.

[6] Under Armour, Inc. (2016, June 28). Under Armour opens UA Lighthouse manufacturing and design leadership center in the brand’s hometown of Baltimore (NYSE: UA), http://www.uabiz.com/releasedetail.cfm?ReleaseID=977392, accessed November 17, 2016.

[7] Ogus, S. (2016, July 19). Inside under Armour’s efforts to innovate apparel manufacturing and energize the city of Baltimore. Forbes, http://www.forbes.com/sites/simonogus/2016/07/19/inside-under-armours-efforts-to-innovate-apparel-manufacturing-and-energize-the-city-of-baltimore/#38616ca150cb, accessed November 17, 2016.

[8] Review, P. (2014, April 16). Beyond the hype: The industrial challenges for 3D printing, Yale Global Online: A Publication of the MacMillan Center, http://yaleglobal.yale.edu/content/beyond-hype-industrial-challenges-3d-printing, accessed November 18, 2016.

[9] Grynol, B. (2013). Disruptive Manufacturing: The effects of 3D printing, https://www2.deloitte.com/content/dam/Deloitte/ca/Documents/insights-and-issues/ca-en-insights-issues-disruptive-manufacturing.pdf, accessed November 18, 2016.

Fascinating – thanks for a great read! This type of innovation is key for elite athletes already benefiting from digitization (e.g. performance tracking via FitBit and Whoop, used by Lebron James), even at a high cost. As you noted, I’m somewhat skeptical of mass adoption, beyond extreme hobbyists and enthusiasts – at what prices can Under Armor offer personalized, 3D-designed and printed items for the mass market? Traditional input pricing and labor in developing countries may be on the rise, but high-margin consummables (I’ve seen 60%+ net profit when looking at 3DP investments on last job) and skilled U.S. local labor easily surpass that. Furthermore, can this job-shop model be sustainable to address an increasing customer demand?

Such a cool article; thanks for writing! One question I have after reading it is how the competitive landscape is likely to change when 3D printing becomes more prevalent in the footwear industry. While Under Armour has built their brand on a perception of high quality, performance grade wear [1], I wonder whether consumers actually care about having a custom Under Armour shoe vs. a no-name custom shoe in the future. Will providing the raw materials for such shoes become a more differentiated industry than the actual manufacturing of the shoe once 3D printing is a commoditized process?

[1] Horne, L. New Product Development in Textiles: Innovation and Production. 24:24, 2012. Google Books. Web.

Thanks, Karan – really enjoyed your post. Fascinating example of how Under Armour is looking to gain greater control over its supply chain. One concern that I’ve got would be around scalability, i.e. how will Under Armour partner with its retail distributors to provide the 3D printing capability? Or is the plan to just start with the offering in Under Armour’s own stores? It will be interesting to see how athletic companies look to differentiate themselves in 3D printing and what the distribution channels will look like.

Karan — awesome post. As a runner who has struggled to find the right shoes over the years, I hope this technology takes hold. I’d be first in line to get my shoes customized. I also think consumer willingness to pay would (or at least should) be quite high. The average runner is advised to trade in their shoes every 300-500 miles. Assuming an average run of 3-5 miles, this equates to 300-500 runs. Imagine the custom shoe had a sticker price of $500, over 5x the price of an average running shoe. At such a cost amortizing the shoe over 300-500 runs would equate to a cost per run of between $1.00 and $1.67. In contrast, a Soul Cycle class is $34 (pre-shoe rental). So even at $500, a custom shoe equates to a cost per work out of 20x-34x less than Soul Cycle. I might just be blind to the appeal of Soul Cycle, but splurging on some dope kicks just seems to be the better deal here.

Karan, this was a very interesting read ! I had heard about 3d printers but did not realize that this technology can be used to actually make running shoes. It does seem like a great idea to get a shoe which is exactly contoured for one’s feet. However, I am a bit skeptical about the costs that are involved. While the value that will be generated for Under Armour is immense, I am not sure how the costs will be passed on to the consumer. Technology innovation in manufacturing processes needs to create value for both customers and manufacturers for optimal benefit. I had a look at the their current collection of shoes and it seems that the price point mentioned by Sam above is much higher than the current prices at which they sell shoes. The soles itself seem to have added a premium to shoe costs [1] Maybe a starting point would be to ascertain how many consumers who bought Under Armour shoes, would actually like a better contoured shoe. This will help in estimating the demand and distribution of costs. The key point might be scalability here. If the costs of producing 3d printed shoes can be brought down to an extent where the premium is not so much for consumers, then we will truly see the athletic footwear market get disrupted.

1. https://www.dezeen.com/2016/03/19/under-armour-3d-printed-architect-trainers-design-sportswear/

This is great! To me, the biggest value-add of this process is that it largely solves the demand planning / inventory management problem. Apparel / shoe companies are constantly working to offload styles/sizes/colors that didn’t sell, which is why Professor Shih’s T.J.Maxx stock is performing so well. If Under Armour could scale made-to-order manufacturing, it would be great for their bottom line and the environment. In response to Jasper’s comment above – I think the best way to roll out this product would be online-only – similar to how Nike offers their customized Nike ID shoes. I think the novelty of custom-printed shoes would be exciting enough that customers would happily wait a couple weeks to receive their orders.

that would be great because they will be able to improve the parts more and test them easily http://www.agirlwhomakes.com