Will Fortive Ride the Wave of the New Industrial Revolution?

“Indeed, many S&P 500 companies wish they had developed their internet strategy earlier. Those that did now have an advantage. Five years from now, we will be saying the same about AI strategy.” – Andrew Ng, HBR, Nov 2016.

“Indeed, many S&P 500 companies wish they had developed their internet strategy earlier. Those that did now have an advantage. Five years from now, we will be saying the same about AI strategy.”

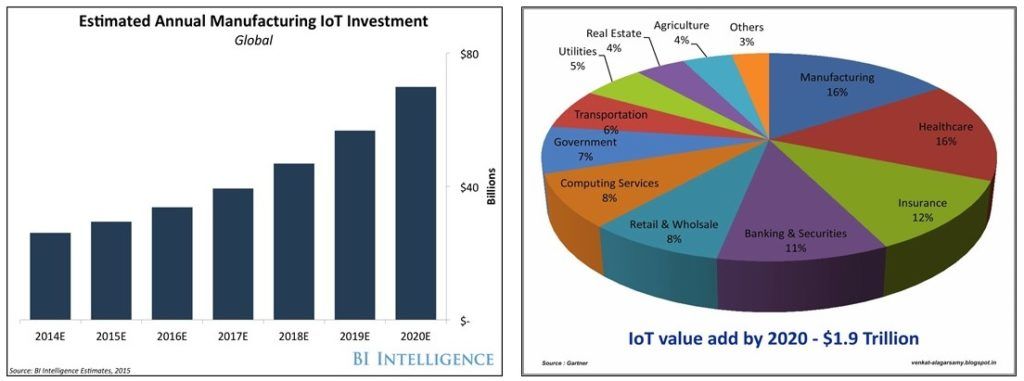

Andrew Ng offers this valuable insight in a compelling HBR article this month [1]. This insight could prove particularly powerful to manufacturing companies. Think of all the possible effects if a factory knew how to measure, store, and analyze the right data! For a company to implement AI, however, it needs to have the right tools in place – a ‘smart’ factory is essential. Companies have already started moving towards creating digitized factories connecting to the Internet of Things (IoT) [2], and companies such as Fortive have positioned themselves remarkably well to take advantage of this shift in practice [3][4].

Largely a producer of manufacturing equipment, Fortive, a Danaher spin-off, prides itself on producing cutting-edge equipment to help businesses create smarter factories that are part of the IoT ecosystem. Its business strategy takes advantage of its expertise in producing sensing and measuring equipment (existing business segment) to create smart industrial equipment [3], thus enabling its customers to monitor and record various forms of data on the cloud. Generally, industrial equipment have longer lifetimes, while the lifetime of sensors, controllers and related software are much shorter [5][6]. So, by selling their industrial customers equipment that is bundled with such sensors and software, Fortive has created a useful avenue of staying connected to the customer throughout the lifetime of its industrial equipment products. If Fortive can transform their customer relationships into partnerships, it can gain access to customers’ production data and use it to ride the new wave about to hit mainstream manufacturing – artificial intelligence. Below are some areas where AI-driven product offerings by Fortive could add value to the customer:

- Predicting demand

Imagine a management team trying to predict demand of DSLR cameras in the situation that Christmas is in two months, a new marketing campaign is about to be launched, but the local economy has been less than prime. Given a large amount of prior demand data in different situations, it is much faster for algorithms to predict future demand than it is for humans to do so by sifting through so much information. Such predictive capabilities could no doubt be immensely beneficial to manufacturing businesses.

- Scheduling production

When a factory starts manufacturing a new product, AI can help them decide how production should be scheduled, given the historical inefficiencies that the plant has experienced with prior new products.

- Analysis of production parameters

Most companies monitor various parameters during a production run that are known to affect product quality. Often times, however, plants do not understand all the parameters that affect quality – external factors such as humidity in the plant or the pH of incoming city water are good examples of overlooked factors. Being able to monitor, record, and analyze these parameters and being able to link them back to the quality of the produced good can help employees understand how to better control the process, leading to better overall quality.

- Defect monitoring:

Speaking of quality, defect monitoring is another aspect where smart machines can lead to great change. For many production lines, it is hard for the human operator to spot defects until the entire production run is over, while sometimes, defects are difficult to spot with the human eye even after production is complete. With the right data, machines can be taught what a defect means for a specific product, and can monitor the progress of materials through the process to detect even minute defects in real-time as well as the point of origin of such defects.

- Inventory management:

Teaching machines to keep track of consumables during production and to automatically send orders to suppliers as stocks run low can help real time inventory management, and can also help suppliers better manage demand. [7]

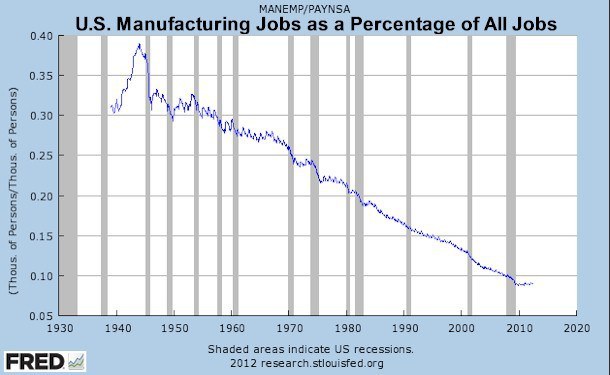

Finally, while the technological capabilities discussed in this post can likely replace only parts of a human job, it is a matter of time before production processes become entirely automated. This will lead to the loss of many blue collar jobs, while economies continue to favor white collar jobs to maintain competitiveness in global markets. However, if we truly regard ourselves as leaders, we will need to find ways to help those who will be affected by such changes. Creating the resources and the culture to help factory workers acquire lucrative skills could be part of the CSR activities undertaken by companies such as Fortive. After all, as we continue to invest in technology to create a better future for us and our neighbors, we must remember to also invest in making sure our neighbors can truly enjoy the increasingly technological future that lays ahead.

(798 words)

Sources:

- Ng, Andrew. “Hiring Your First Chief AI Officer.” Harvard Business Review. N.p., 11 Nov. 2016. Web. 17 Nov. 2016.

- By Markus Löffler and Andreas Tschiesner. “The Internet of Things and the Future of Manufacturing.” McKinsey & Company. N.p., June 2013. Web. 17 Nov. 2016.

- “Extraordinary Teams. Extraordinary Results.” Fortive Homepage |. N.p., n.d. Web. 17 Nov. 2016.

- Danaher 2015 Overview Presentation. N.p., n.d. Web. 17 Nov. 2016.

- Samaha, Lee. “3 Companies Set to Win the Industrial Internet of Things.” The Motley Fool. N.p., 01 Apr. 2016. Web. 17 Nov. 2016.

- Abbink, John. “Danaher’s Spin Off: What Investors Need to Know About Fortive.” The Motley Fool. N.p., 13 Jan. 2016. Web. 17 Nov. 2016.

- “These Factories Are Crunching Production Time with Artificial Intelligence.” Business Insider. Business Insider, Inc, 09 July 2016. Web. 17 Nov. 2016.

-

“Intelligent Approach to Zero-defect Manufacturing – Horizon 2020 – European Commission.” Horizon 2020. N.p., 26 Mar. 2015. Web. 17 Nov. 2016.

-

“China, Robots/Automation and Unemployment.” Econfuture | Robots, AI and Unemployment | Future Economics and Technology. N.p., 21 Aug. 2012. Web. 18 Nov. 2016.

Great write-up with an appropriately titled article! As we drive into the future, current economic growth prospects look less optimistic than those seen in the past century. Consequently, as we transition out of our current long-term debt cycle into a new period of growth, we will increasingly need to rely on productivity improvements to drive progress in our standard of living. Cognitive computing represents a huge leap forward in this area, and it sounds like Fortive will harness this innovative technology to enhance capability within diversified industrials. However, as you mentioned, I am concerned about the impact of such enhancements on the current workforce. I’d like to think that humans and machines will complement each other and that people will take on more of a “problem solving” role as their jobs evolve.[1] The only fear I have is that my vision relies on the assumption that machines do not attain the ability to infer meaning from data and make decisions based on that evaluation. Looking back at our IBM Watson case, this assumption may not necessarily hold. With an ever growing population and shrinking pool of jobs, I hope we find a solution that does not leave our workforce behind.

[1] Antonietta Grasso, “Will Machines Replace Us or Work With Us?”, Wired Online, [https://www.wired.com/insights/2015/01/will-machines-replace-us-or-work-with-us/], accessed November 18, 2016.

DF,

Thanks for the insightful post about AI in manufacturing environments. The shop floor definitely seems to be an appropriate place for AI to play a useful role, given the myriad sources of data and value of quick, data-driven decision making in factory settings. I believe your read of the role AI could play in scheduling to be particularly insightful. In addition to scheduling for new product introductions, I think AI could be extremely helpful in adjusting schedules and staffing levels when factories are presented with changes in demand from customers or changes in supply of workers. For example, if a worker fell ill one day and couldn’t come to work, perhaps the AI system could automatically call in an additional temporary worker, direct him to his work station, and balance the line based on his skill level. That would be amazing!

Thanks again for a thought provoking post!