Under Armour and Additive Manufacturing

In the ever-changing athletic footwear landscape, harnessing the power of cutting-edge technology has become critical to brand success and survival. The American sports footwear and apparel company, Under Armour (UA), founded in 1996 by Chairman and CEO, Kevin Plank, has competed on a global stage with some of the largest athletic footwear companies, such as Nike, Adidas, Puma, and New Balance [1]. With sales growth slowing, up only 3% YoY from 2016, compared to 22% YoY from 2015, Under Armour has turned to additive manufacturing (AM) and 3D printing to create innovative products, pushing the boundaries of technology within athletic footwear [2]. As athletes try to gain any edge over their competition, AM could create the incremental benefits these consumers are looking for.

In November of 2017, UA partnered with Electro Optical Systems (EOS), a major player in the space of AM, to advance the use of 3D printing in commercial operations [3]. With this strategic alliance, Under Armour is faced with several questions that other firms must also confront when dealing with the industrialization of AM.

In November of 2017, UA partnered with Electro Optical Systems (EOS), a major player in the space of AM, to advance the use of 3D printing in commercial operations [3]. With this strategic alliance, Under Armour is faced with several questions that other firms must also confront when dealing with the industrialization of AM.

- Should this technology be deployed to enable enhanced product customization for consumers (i.e., mass customization) or to lower standardization costs by making supply chains more efficient?

- Will AM become an operating efficiency used in mass production or is it best used during the prototyping phase within research and development?

- Is 3D printing a technology that can organically merge within a company’s business model or does this technology prompt firms to reconsider how to bring products to market?

These are a few of the questions Under Armour and its competitors are having to ask as AM becomes more practical and cost-effective.

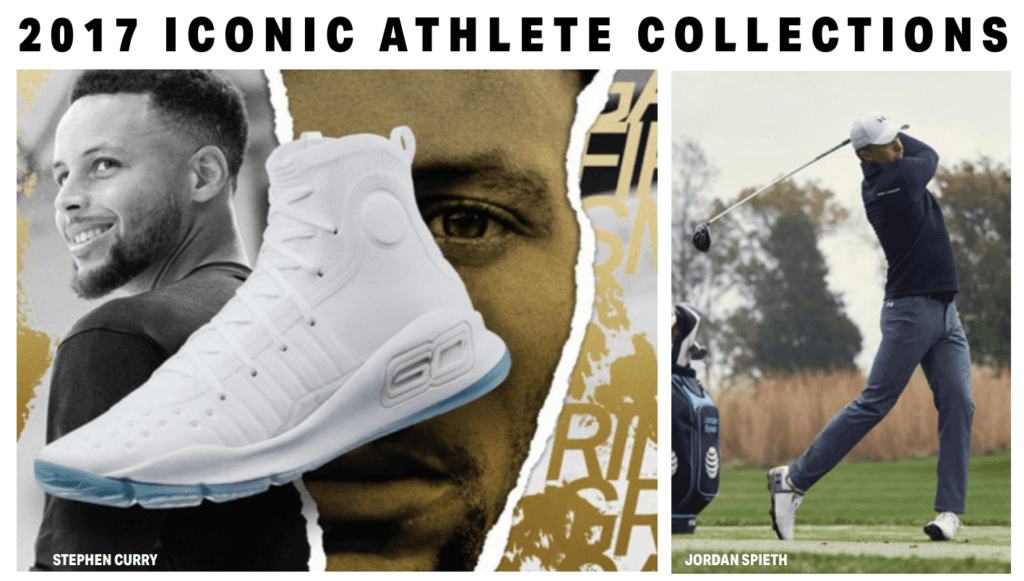

Product development will play another factor when considering the utility of 3D printing for footwear. AM will allow product development teams to become more iterative through its testing phase, but it also allows manufacturing companies to become more service oriented in nature. For example, through the use of lasers and heat to manipulate the mechanical properties of polymers, it only takes a few minutes to produce a midsole for an athletic sneaker using AM [4]. As UA sponsors top athletes such as Stephen Curry, Tom Brady, Jordan Spieth, and Bryce Harper, 3D printing can limit the processing time between prototyping iterations of a sponsored athlete’s shoe, reducing the time it takes to go to market. As these sponsored athletes provide feedback on various prototypes tested during the trial phase, product managers can become more effective and efficient with each adjustment made [5].

In addition, 3D printing can dramatically change the buying experience for customers. Imagine walking into an Under Armour store and having a machine virtually scan a 3D replica of your foot, not only identifying your foot size, but also your pressure points, stride, and stability. After being measured, the customer would have the ability to customize her shoe and have it in her hands within a couple of days given the ability to tailor shoes to each individual with AM.

This notion of a highly customized shoe industry may not be economically feasible however. Many of the advantages of this technology will most likely result in better supply chain and inventory management. Rather than relying on a wide array of suppliers to fulfill raw material requirements, AM allows companies such as UA to bring processes in-house. Specifically, 3D printing adds the most value when creating “complex parts … that could not be made any other way. [6]” Rather than relying on vendors to support low volume, high complexity materials that lack demand visibility, UA has the opportunity to enhance its supply chain capabilities by judiciously investing to eliminate operational headwinds, while removing overhead and labor costs by spending on machine automation [7].

As Under Armour aggressively attempts to grab global share from its largest competitors, how will it use AM to do so? In the short-term, to become a stakeholder in a transformational AM supply chain, UA must continue to make the proper investments and acquisitions to capture the opportunity of using the technology’s commercial applications. In the long-run, companies that can utilize 3D printing to expand margins by procuring lower cost raw materials will yield the greatest competitive advantages. Though Nike and Adidas seem to be the most obvious threats, is it possible for a startup at the intersection of AM and footwear to reshape the branded sneaker landscape? If so, are these sports apparel brands inevitably destined to be disrupted if they cannot commercialize the use of this groundbreaking technology?

[Word Count: 751]

Sources:

1Baer, Drake, “Here’s how Under Armour grew into a $15 billion athletic-apparel empire”, Business Insider, February 19, 2015, https://www.businessinsider.com/history-of-under-armour-2015-2, accessed November 9, 2018.

2Under Armour, 2017 Annual Report, p. 3, http://investor.underarmour.com/static-files/242095c1-f708-4494-afe5-8b7d25415c4f, accessed November 10, 2018.

3”EOS and Under Armour partner…,” press release, November 29, 2017, on EOS website, https://www.eos.info/press/eos-and-under-armour-partner-to-develop-advanced-scalable-laser-sintering-3d-printing-technology, accessed November 8, 2018

4Brown. Chain reaction: Why AM is about to transform the supply chain. Mechanical Engineering 140, no. 10 (October 2018): 30–35.

5Elie Ofek and Ryan Johnson, “Nike Football: World Cup 2010 South Africa,” HBS No. 9-511-060 (Boston: Harvard Business School Publishing, 2013), p. 3-10.

6Brown. Chain reaction: Why AM is about to transform the supply chain. Mechanical Engineering 140, no. 10 (October 2018): 32.

7Kerns. What’s next for 3D printing? The disruptive technology continues to grow thanks to lower costs and greater accessibility. Machine Design 90, no. 1 (January 2018): 36–42.

Source: Sports apparel market share in the United States as of 2017, via Statista, accessed November 12, 2018.

I’m very concerned if the big athletic footwear manufacturers believe that their only advantage with 3-D printing in footwear is better margins and a faster supply chain. If they aren’t using 3-D printing to stay ahead of the curve when it comes to innovation, then I believe they will fall behind and are ripe for disruption.

I love the picture you painted about walking into a shoe store and they can scan your foot to find your perfect size, pressure points, etc. To me this is the future of footwear. Considering that the orthotics market alone is $900M, 3-D printing for your exact foot seems like a NPV positive play for the major footwear players (https://www.inc.com/tom-foster/profoot-makes-50-million-dollars-a-year-selling-sexy-orthotics.html). I truly believe if they don’t do it, then a start-up will come in and start to claw up market share, similar to what Under Armour did with it’s performance wear.

I think Under Armous is uniquely positioned to exploit this technology, as they have the current supply chain and logistical leverage with suppliers while maintaining the smaller player agility to make disruptive changes in the footwear market. I’m curious regarding the idea you presented of having a custom shoe built to your specifications, specifically I wonder if it is possible to customize only one part of the shoe (ie: sole) with the remaining portions of the shoe standard to size and width as they currently are. This may allow for smaller stores or production facilities locally to print the specified sole and then simply combine it with the remainder of the stock shoe in a small, controlled process.

While I believe the opportunity for a startup to disrupt the industry is clear, the ability of a semi-established brand like Under Armour to limit the impact of the required marketing spend would provide it a huge advantage, and it’s position relative to Nike, Adidas and others provides massive upside to entice them to pursue this.

I find your perspective that 3D printing as a potential powerful game-changer in the footwear industry very interesting, as I do have difficulty reconciling how much of a disruptive force it could be. On one hand, I can see that the innovative part could change the entire industry landscape, especially the point on the concept of “walking into an Under Armour store and having a machine virtually scan a 3D replica of your foot, not only identifying your foot size, but also your pressure points, stride, and stability”. And I do share the same doubt on how feasible this could be from a price-value standpoint (i.e. will that incremental benefit of customization cover the cost, or will technology improve to the point where commercialization is possible). On the other hand, I do think that 3D printing only covers and improve the functional element of a sneaker. When it comes to footwear, there seems to be a lot more emotional aspects in play in the brand, as we saw in the Nike case study where many of the consumers are buying it more for aspiration resonance than the functional aspect. Function ultimately could just be a baseline, and 3D printing could hardly replace the emotional human element of a sneaker design. Much like a vintage watch, even with digitization of the watch industry, many consumers still hanker for the heritage that is tied to the watches. Hence, I’m in two minds about this and would be keen to see how the industry develops.

This was an excellent read! I really liked your description on what it would be like to walk into a UA store and have the company 3D print a custom shoe for you on the spot. Upon further research, it looks like adidas has actually already released models that are utilizing 3D printing: https://techcrunch.com/2017/04/07/adidas-latest-3d-printed-shoe-puts-mass-production-within-sight/. Regarding your question on if the incumbent footwear players will be disrupted by a startup — I think it’s very possible. While clearly players like adidas are moving quickly with respect to 3D printing, I do think its possible for new entrants who focus on the customization aspect of 3D printing to gain traction. As someone who has worn custom orthotics in my running shoes for years, I think customized insoles could be a massive market for UA or other footwear players. Custom orthodics can cost hundreds of dollars, so I think there is a massive product opportunity for footwear players to incorporate this into standard footwear.

Your article is very interesting. It clearly explains the challenges that Under Armour faces in relation to the adoption of additive manufacturing.

In relation to your question regarding how competitors will adopt this technology, I think that most of the important players of the footwear and apparel industry will use additive manufacturing to transform their customer experience. This technology allows for higher customization, and this is essential in a context in which customers demand more personalized items. While some brands are working on the idea of printing cloth at their stores, some start-ups are working on the concept of printing cloth at home (see cited article). [1]

In that context, it is hard to imagine what role companies such as Under Armour will play in the footwear and apparel industry. Will they stick to the concept of selling cloth, or will they change their business models to sell designs for people to print cloth at their homes using 3d printers?

Evidently, additive manufacturing is disrupting the footwear and apparel industry, and companies will have to adapt to an increasingly dynamic environment.

[1] The Future of Fashion Is 3D Printing Clothes at Home, James Tarmy, Bloomberg, April 15th 2016, accessed November 2018, https://www.bloomberg.com/news/articles/2016-04-15/3d-printing-is-poised-to-bring-haute-couture-into-the-home

Great article with thought provoking questions and suggestions.

In terms of the choice between using 3D printing for highly customized experience or to lower supply chain cost, I wonder if both are mutually exclusive at all? To me, the market might exist for highly customized shoes (in a certain segment or certain application or sports) but another market might exist for highly standardized products. To that end, UA should still consider if there’s indeed market for both and how UA can be most competitive.

I also wonder if there’s already a startup trying to disrupt this industry… Is it just a matter of time before we can take scans or our feet using smartphones and sending it to the company to get our highly customized shoes? Or is it indeed that there’s not really a market for such product?

I find the opportunities of additive manufacturing (AM) fascinating, and am enthused by how Under Armour and Adidas are rushing to develop mass market products with AM. However, I question what is the source of value creation for those sports companies; should UA focus on identifying and endorsing promising athletes or deep-dive into how technology (e.g., AM) can deliver better products? From Nike’s case, we have seen that foresight in athlete endorsement can dramatically shape the company outlook and its competitive landscape (e.g., endorsing the Brazil team in 1994, and developing the Air Jordan).

This was an excellent read, thanks for sharing! I think the opportunity for high customization in the shoe industry represents a massive gap in the market and a huge area for growth for UA. Shoes and their comfort play a critical role in our lives. As Harvard professor Tal Ben-Shahar shares in his positive psychology class, one of his researched 14 key points explaining how to be happy in your life includes wearing comfortable shoes and clothes. If UA can find a way to customize shoes in a cost efficient manner and be first to market, I think they’ll be the winners in the space.

I am personally a big 3D printing fan, and I found this article fascinating as it exemplifies how 3D printing is transforming yet another industry. While it is true that 3D printing has the ability to easily create more complex products which otherwise could not be created, what I find especially interesting about the transformation happening in the clothing industry is that it is a double transformation. 1. 3D printing allows to create more complex products 2. (IoT) Internet of Things and wearable electronics are integrating slowly into the fashion world. Given these two transformations which are happening now at the same time with regards to the question: “If so, are these sports apparel brands inevitably destined to be disrupted if they cannot commercialize the use of this groundbreaking technology?” I believe the answer is a strong YES. And the reason is whoever will be innovative early adaptor with these early technologies will basically reap the benefits of two transformations at once. I am personally going to work this winter-break on a startup idea that uses these 2 technologies to create wearable tech in the HBS Startup-bootcamp as I believe this field is very hot and still has enormous potential.