The Drone Buzz: How Kespry Transforms Physical Jobsites into Big Data Sets

What happens when you give a miner, construction worker, and roof inspector a drone?

Have you ever walked past the construction gate circling the soon-to-be Klarman Hall and wondered: what’s really happening on the other side of the fence? A sign on the gate sketches a broad vision of the future building. But how is the project progressing on the ground? What if – from the safety of your laptop – you could log into myHBS, open a link to the Klarman project site, and virtually explore a scaled 3D model of the full grounds, gaining richer and more accurate insight than would be possible by crossing the fence? You could answer:

- Whether every base point of that hole in the ground is at the right depth and levelness to safely begin building;

- If the volume and mass of a new pile of raw material reflects what HBS paid for;

- Whether today’s progress – at every spatial point – matches the plan;

- How many hand tools have been accidentally dropped across the site – oops!

These questions and beyond are what construction, mining, and insurance companies ask and answer through Kespry, a first-mover digitizing drones that turn the physical jobsite into a big data set.

While numerous companies large and small have tried to capitalize on the drone hype with varying success, Kespry is winning customer acquisition in time-old industries previously set in their ways by leveraging the power of digitization.

How exactly does this work? How has Kespry digitized what it does, beyond being a commercial eye in the sky? After all, the hardware just looks like a quadcopter with a camera, right?

No Joysticks: Safety and Efficiency

While Kespry began as a remote-controlled widget, the end user now merely pushes “go” in Kespry’s iPad app to make the drone take off, fly, collect imagery and telemetry, transfer that data to the cloud, and land – all on its own. The app uses simple inputs from the user including flight area and height to algorithmically generate an optimal flight path.[1] Through localized wireless internet and a computer with embedded software on the drone, the app and drone maintain communication to display in-app flight progress and send collected data to the cloud for automated processing.[2]

Behind the software are engineers who have dabbled in flying cars, R&D for BMW’s Connected Cars Group, as well as SpaceX’s first software developers, formerly handpicked by Elon Musk himself.[3]

From Physical Stuff to Actionable Data

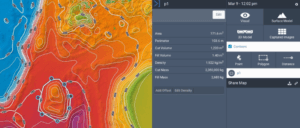

Once flight data is transferred to the “Kespry Cloud,” it is stitched into various virtual, interactive maps (topographical, elevational, 3D view) with millions of mineable data points as well as downloadable files and reports.[4] A jobsite manager can not only pinpoint the latitude, longitude, and altitude of any visible point on the site, but aggregate these points to instantaneously calculate volume and mass of objects; once an object is measured, the Kespry Cloud automatically generates reports for management and sharing.[5]

Source: Kespry, Inc. website: http://kespry.com/products/kespry-cloud

Through a partnership with NVIDIA, Kespry is pioneering the intersection of drones and artificial intelligence with the Jetson TX1, a “deep-learning” chip that enables recognition, classification, and quantification of objects and patterns.[6] The following image depicts how this can be done with large objects; for subtler objects, Kespry is helping insurance giants such as Allstate inspect various types of roof damages and adjust claims.[7]

Source: NVIDIA Company Blog: https://blogs.nvidia.com/blog/2015/11/19/kespry-jetson-tx1/

With an end-to-end digitized solution, Kespry ultimately helps its clients operate more efficiently, cost-effectively, accurately, and safely. For example, a client Whitaker Construction tracked that with Kespry, they can take inventory twice as often, in a quarter of the time, reducing costs by 22%.[8]

What’s Next for Kespry?

Kespry is literally on the up-and-up. With more than $26 million in venture capital raised and $4 million in revenue earned in its first year on the market alone, [9] what could Kespry possibly do next?

Network Effects

As Kespry’s customer use scales, and as each new drone flight captures millions of data points, Kespry could (with customer willingness) aggregate this data to deliver valuable industry insights to clients. If clients were open to contributing aggregated, anonymized data for the purpose of network benefits, clients could use this data benchmark themselves, whether it be material density inputs, how ahead of or behind schedule their projects are compared to industry standard, or use cases others have discovered and gained additional value from.

Other Enterprise Software Integration

Kespry is capturing critical information about assets, operations, and projects for its clients. Kespry’s data is rich, but in a silo. The company should consider integrating, for example, with ERP tools its mining customers may use, or AutoCAD-like programs its construction clients use to seamlessly ship value-adding data between programs that could generate increased customer value and stickiness.

Word Count: 792

[1] Interview with John Jessen, Head of Mobile at Kespry, Inc.

[2] Ibid.

[3] Paul Doersch, “Open Letter from Kespry Founder.” http://kespry.com/careers

[4] Company website. http://kespry.com/products/kespry-cloud

[5] Ibid.

[6] Brian Caulfield, “Kespry Shows How Jetson TX1-Powered Drones Can Keep an Eye on Construction Sites,” November 19, 2015. https://blogs.nvidia.com/blog/2015/11/19/kespry-jetson-tx1/

[7] Jonathan Vanian, “Allstate Just Used Drones to Inspect Homes in Texas,” September 2, 2016. Fortune. http://fortune.com/2016/09/02/allstate-drone-home-inspection-insurance/

[8] Company website. http://www.kespry.com/drone-stockpile-cost-savings/?utm_content=bufferbe783&utm_medium=social&utm_source=twitter.com&utm_campaign=buffer

[9] Ryan Mac, “Enterprise Drone Maker Kespry Closes $16 Million Round With New FAA Regulations In Sight,” June 21, 2016. Forbes. http://www.forbes.com/sites/ryanmac/2016/06/21/enterprise-drone-maker-kespry-closes-16-million-round-with-new-faa-regulations-in-sight/#460708e27ef0

Excellent example of how technology is completely altering how certain businesses operate – in this case the operation being surveying areas. I’d definitely be interested in the continued expansion of drone land surveillance in the private and public sector; for example, it looks like the maps drawn from the drone are quite detailed, picking up small nuances in topography and etc. You hear about those hiking horror stories where someone gets lost in the middle of a mountain and has no way of contacting the outside world, while volunteers scour vast areas for the missing. I can see so much utility in say the National Parks Department having one of these drones running a pre-set flight daily to scan for any anomalies, potentially saving lives.

I love the idea of using robotic technologies to increase efficiency and improve safety at mining sites. During our Cynthia Carroll case, I couldn’t help but wonder why we are still sending humans down into the dangerous mines when we could legitimately reach “zero harm” if we sent small robots down there instead to mine and analyze geology to make sure everything is safe. Thus, Kespry could continue to expand its technology from drones to include “rovers” that would have all of the necessary physical and analytical tools.