Taking Jeans from Blue to Green: How Levi Strauss is Reducing its Water Consumption

A pair of jeans – from its days as a cotton seed to its drop-off at Goodwill – can use nearly 3,800 liters of water. Can the Levi Strauss Water<Less process help reduce this consumption?

You probably already know that you could save a lot of water (up to ten gallons!) if you just shortened your shower by two minutes.[i] But did you know that your choice of denim could also have an effect on water consumption? One pair of jeans – starting from its days as a cotton seed to its drop-off at Goodwill – can consume nearly 3,800 liters of water[ii]. However, iconic jeans brand Levi Strauss is working to lower this number with its Water<LessTM process. Launched in 2011, Water<LessTM reduces water consumption in three main ways: cotton production, jeans manufacturing, and consumer care.

Cotton Production

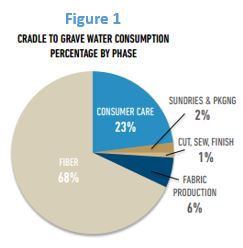

Levi Strauss conducted a “lifecycle assessment” of its classic 501® jeans and found that more than two-thirds of a pair of jeans’ lifetime water consumption is due to the fiber[iii], or cotton production process (see Figure 1). Cotton is a water-intensive crop, and climate change and water scarcity are likely to strain the global production of cotton.[iv] Therefore, Levi Strauss helped establish the Better Cotton Initiative (BCI) to change how cotton is grown, both decreasing the environmental impact and improving labor standards and economic livelihoods for farmers. Using practices like drip irrigation, BCI farmers utilize up to 18% less water than their peers. In 2015, Levi Strauss sourced 12% of its cotton from BCI.[v]

Jeans Manufacturing

While an average pair of Levi’s requires 42 liters of water during the finishing process to achieve the proper “worn-in” look, Water<LessTM jeans require far less; some styles only need 1.5 liters, relying heavily on rocks to do the smoothing.[vi] When combined with water recycling and other water consumption savings in the process, this means that making a pair of Water<LessTM jeans uses up to 96% less water than a typical pair of jeans.[vii] Since 2011, Water<LessTM has reduced water consumption in the manufacturing process by more than 1 billion liters[viii] while creating over 75 million products.[ix]

Consumer Care

Given the typical lifetime and washing & drying frequency of a pair of jeans, consumers are responsible for the next greatest share of water consumption after cotton production. Hence, Levi’s created product care tags encouraging consumers to “wash less, wash in cold, line dry, and donate when no longer needed.”[x] In addition, the company has famously recommended that customers stick their jeans in the freezer to kill germs in lieu of tossing them in the washing machine. Although the latter idea has been contested[xi], both practices will reduce the consumer’s water footprint.

What’s next?

Customers seem to like the Water<LessTM idea: in 2011, Levi Strauss claimed that its jeans marketed as less water-intensive sold better than their similarly priced but more traditional counterparts.[xii] Levi Strauss is pleased as well and intends to make 80% of Levi’s products using the Water<LessTM process by 2020, up from almost 25% today.[xiii]

Levi Strauss certainly deserves credit for designing an innovative process to conserve water during the jeans manufacturing process, and for encouraging more water conservation both upstream and downstream. However, the fact remains that it is fundamentally a jeans company, and selling as many jeans as possible is in its best interest. If the Water<LessTM products are functionally similar to Levi’s traditional products, do customers really have an incentive to treat them differently? Levi’s may say they want customers to wash their jeans less frequently, but doing so would reduce the wear and tear, thereby lengthening the replacement time and hurting Levi’s sales. In order to better align incentives, perhaps Levi Strauss could spend some time exploring innovations in stain- and smell-resistant denim. Such features could both allow Levi Strauss to charge a premium for their higher quality product and put customers more at ease over skipping their weekly laundry cycle to save some water.

[799 words]

[i] “Take Shorter Showers.” Sustainability@BU, http://www.bu.edu/sustainability/what-you-can-do/ten-sustainable-actions/take-shorter-showers, accessed November 2016.

[ii] Levi Strauss & Co. “The Life Cycle of a Jean: Understanding the environmental impact of a pair of Levi’s® 501® jeans,” http://levistrauss.com/wp-content/uploads/sites/4/2015/03/Full-LCA-Results-Deck-FINAL.pdf, accessed November 2016.

[iii] Levi Strauss & Co. “The Life Cycle of a Jean: Understanding the environmental impact of a pair of Levi’s® 501® jeans,” http://levistrauss.com/wp-content/uploads/sites/4/2015/03/Full-LCA-Results-Deck-FINAL.pdf, accessed November 2016.

[iv] WWF. “Sustainable Agriculture: Cotton,” https://www.worldwildlife.org/industries/cotton, accessed November 2016.

[v] Levi Strauss & Co. “Sustainability: Planet,” http://www.levistrauss.com/sustainability/planet/#water, accessed November 2016.

[vi] Leslie Kaufman, “Stone-Washed Blue Jeans (Minus the Washed),” New York Times, November 1, 2011, http://www.nytimes.com/2011/11/02/science/earth/levi-strauss-tries-to-minimize-water-use.html, accessed November 2016.

[vii] Levi’s. “The lifecycle of Levi’s® jeans,” http://store.levi.com/waterless/index.html, accessed November 2016.

[viii] Levi Strauss & Co. “Sustainability: Products,” http://www.levistrauss.com/sustainability/products/waterless, accessed November 2016.

[ix] Levi’s. “Made of Progress”, http://www.levi.com/US/en_US/madeofprogress#process, accessed November 2016.

[x] Levi Strauss & Co. “Sustainability: Planet,” http://www.levistrauss.com/sustainability/planet/#water, accessed November 2016.

[xi] Sarah Zielinski, “The Myth of the Frozen Jeans,” Smithsonian Magazine, November 7, 2011, http://www.smithsonianmag.com/science-nature/the-myth-of-the-frozen-jeans-129092730/?no-ist, accessed November 2016.

[xii] Leslie Kaufman, “Stone-Washed Blue Jeans (Minus the Washed),” New York Times, November 1, 2011, http://www.nytimes.com/2011/11/02/science/earth/levi-strauss-tries-to-minimize-water-use.html, accessed November 2016.

[xiii] Levi Strauss & Co. “Sustainability: Products,” http://www.levistrauss.com/sustainability/products/waterless, accessed November 2016.

TD21,

This was an interesting take on jeans – a very tangible and specific product that we regularly use. I definitely agree with your view that Levi Strauss deserves credit for designing a process that reduces water consumption at the manufacturing level. You also do a great job of going beyond production to describe the impact consumers have on water consumption during the product’s lifespan through regular washing. I agree with your view that promoting less washing is generally in conflict with Levi’s business goals, as less wear and tear would result in longer replacement times.

However, I would like to push back on the action-plan you have proposed as I don’t necessarily think it resolves the tension between longer replacement times and fewer consequent sales. You mention how “in order to better align incentives, perhaps Levi Strauss could spend some time exploring innovations in stain- and smell-resistant denim. Such features could both allow Levi Strauss to charge a premium for their higher quality product and put customers more at ease over skipping their weekly laundry cycle to save some water.” What is stopping Levi’s from charging a higher price for environmentally friendly goods in the first place? Recent reports suggest that consumers are willing to pay extra for a product from a company known for being environmentally friendly as opposed to other purchasing drivers. [1] What makes you believe that customers would pay more for “stain- and smell-resistant” denim? Additionally, this would presumably reduce washing even more, further exacerbating the tension between sustainability and sales goals.

The question that I would ask myself is whether there is a ceiling regarding potential price increases given Levi’s customer promise of providing high quality, affordable jeans. If so, what alternative solutions could you find that might decrease the misalignment in incentives you describe? Maybe Levi’s could consider selling special washing products for their jeans to provide an additional revenue stream? Other options might revolve around having incentive programs in which you can donate old jeans to be recycled in exchange for a discount on new jeans to incentivize higher turnover? I think that this is a particularly tough example because Levi’s jeans don’t tend to go out of fashion as they have a rather traditional style. Another idea might be to explore product lines that are more “fashionable” and more likely to be recycled after a few years. Here, you potentially could take market-share away from more fast-fashion companies that don’t have sustainable production if consumers really do care about purchasing from eco-friendly firms.

[1] Nielsen, “The Sustainability Imperative: New Insights on Consumer Expectations”, October 2015

Thanks, Maria! I agree that Levi Strauss could charge a higher price. My concern is that it could be challenging for them to raise the price of these jeans now that they are already on the market, as customers are likely to be sensitive to such an increase if they are already accustomed to paying a certain price for that product. However, if they were to add features or somehow innovate on the first iteration of the Water<Less products, perhaps they could charge a higher price without much disruption. Stain- and smell-resistance are just a few potential features that could be added (as stains and smells are common reasons for more frequent washes, according to the Levi Strauss CEO) but there are certainly other options!

Agree with you that Levi’s has taken a big step toward introducing sustainability in its supply chain. A couple of thoughts on things they could do differently. First, I think that promising to make 80% of jeans in Water<Less program by 2025 is a pretty generous goal. I think that it can be fairly challenging for companies to come up with innovative ways to introduce sustainability into their supply chain. However, once they have an idea, I don't believe it should be that hard to scale. I think the 2025 goal signals Levi's fear of reduced financial performance with the onset of the sustainable jeans program (since their business thrives on consumerism). Second, I wonder if the quality of the jeans would be at all compromised with this program. If so, it could induce consumers to wash their jeans more frequently, partially offsetting the impact of the Water<Less program – I disagree with the point that anti-smell or -stain jeans are a viable option because I just don't think that consumers can get comfortable with that. I think Maria's point above about a recycling program is interesting – it is something that is used in the shoe industry (particularly running shoes because they have a short lifetime). However, the challenge with these is that that element of the supply chain is now out of the company's hands and they are reliant on the consumer to be willing to take on the burden to recycle the jeans in store (and receive a discount). I think that Levi's could absolutely charge more for their sustainable jeans – conscious consumers are typically willing to pay more and this would relieve the financial burden of the program a bit and make it more appealing to the Levi's.

I like this post a lot TD21, since I have some experience in the garment industry. My former employer produced all the labels that go into these Levis jeans, from the white label with the washing instructions to the brown patch that goes in the back of the jeans on the belt area. One of the main quality tests that Levis (our customer) did to our labels was washing tests, where they would put our labels sewed to the jeans through many washing cycles to see how many cycles the ink resisted before getting washed out. In order to have this performance on our labels we had to develop an special kind of ink that was solvent based which could potentially be harmful to the environment. If Levis was suddenly able to reduce their criteria on number of wash cycles that our inks needed to resist, we would definitely look for more environmentally friendly inks which could ultimately have a positive effect on the environment as well and could be offered at an even better price.

I really liked how you defined the responsibility of Levis as not just what happens inside the four walls of their production plant, but also what happens upstream and downstream their supply chain process. I think that going forward they could definitely profit from collaborating with their current suppliers to see where exactly they might be also having a negative impact on the environment and work with them to solve the issues.

Thanks for sharing, it is exciting that Levi’s has taking a leadership role in making a jean which requires 96% less water. I had no idea it took nearly 3,800 liters of water to produce a normal pair of jeans. While Levi’s has made some production technology enhancements, I found the Levi’s Water<Less strategy has more of a marketing campaign. Based on their website, I felt that the company was promoting sustainability through engaging their end consumer in effective marketing campaigns. Now that Levi's has created the Water<Less production process, it seems to be just pushing the onus of conservation and sustainability to the end consumer. Shouldn't Levi's be trying to invest in more R&D efforts to further reduce its water footprint? Do you agree that Levi's Water<Less has evolved into a marketing platform and that the company has stalled its efforts to further improve the environmental efficiencies of their supply chain and production operations?

I definitely agree that it is part of a marketing campaign, but I actually think Levi Strauss has made steps to innovate and further reduce its water footprint. While some of the jeans in the Water<Less line initially reduced water consumption an average of 28%[1], they have managed to bring that number down significantly to make some jeans requiring 96% less water. It is also trying to reduce its water footprint by sourcing more sustainable and recycled cotton; while it sourced 12% of its cotton from the Better Cotton Initiative (BCI) in 2015, its goal is to use 100% sustainable cotton by 2020[2]. I think many of its efforts to decrease water consumption by engaging suppliers, consumers, and other apparel manufacturers and even spreading awareness among its workers and communities have been great. It has partnered with organizations such as BCI, the National Resources Defense Council, Project WET Foundation, and even developed its own standards and requirements to try to improve these processes (you can read more at the second link below, if you are interested.) But yes, it can certainly do more and invest more R&D into improving its own processes!

[1] Levi's, "Levi's Water<Less Jeans Finishing Process", http://store.levi.com/waterless, accessed November 2016.

[2] Levi Strauss, "Sustainability: Planet", http://levistrauss.com/sustainability/planet/, accessed November 2016.

Very interesting article. It is a great example of how sustainability is a way of life and not just project. I believe it would change the comsumer habits of people if they were aware about the environmental impact of the products they buy.

Reading this article I thought that maybe it would be a nice idea to put on all consumer products a tag with their environmental footprint. For example Levi’s Jeans: 1) 40lt of water 2) 500gr CO2 emissions 3)1.2kg waste disposal 4) 5KWatt energy consumption. In this way we would create awareness and give incentives to companies to be more environmentally friendly.

Being a big fan of fashionable jeans, I remember once Levi’s CEO reportedly said:”Your jeans should never see the inside of a washing machine.” It is interesting that you mentioned:”…doing so would reduce the wear and tear, thereby lengthening the replacement time and hurting Levi’s sales..” Jeans, as casual fashion essentials, may not be replaced only when it’s broken. I remember there were countless times I opened my wardrobe and decided to donate some of my old-love jeans simply because they went out of style –among them were even some really expensive ones; I also remember there were many times I went shopping and decided to buy a couple of new pairs of jeans just because I wanted to collect the new styles, while knowing I already have jeans at home.

So I wouldn’t assert there is a conflicts between pushing sales and urging people to wash their jeans less. I also question the viability of charging a premium for jeans that are stain- and smell- resistant as they may push people to just buy regular-priced jeans. I think the key driver of sales still rests within the design of the jeans, which are essentially fashion essentials.

Thanks for sharing a clear, focused piece on water conservation efforts by Levis. I am intrigued by their innovative Water<Less manufacturing process which seems to be scalable and the 96% less water use is impactful. I also appreciate Levis efforts in looking at the holistic end to end supply chain to drive these efforts. However, there are three areas where Levis needs to do more in my opinion i) First Levis is only sourcing 12% of the cotton from BCI which is negligible to create impact in terms of farmers livelihoods or water conservation. Given cotton production is a highly water intensive process, I would expect Levis to run with the BCI idea and scale it quickly ii) Levis needs to do more to change consumer behaviors by designing marketing campaigns that introduce the lifetime/non-laundering concept possibly leveraging it as a unique selling proposition and iii) Levis can extend environmental impact efforts beyond water conservation to energy efficiency to create a more holistic environmental lifecycle agenda. It can start from direct operations and then extend to the entire value chain possibly engaging consumers with the non laundering concept to drive efficient energy use.