Printing Ideas: Innovating Ford’s Product Development Cycle through Additive Manufacturing

How additive manufacturing (3D Printing) has become ingrained in Ford's product development cycle through rapid prototyping.

Additive manufacturing or 3D printing within the automotive industry has been heralded as a revolutionary technology for original equipment manufacturers’ (OEMs) supply chains and vehicle design.[1][2] Whether OEMs believe 3D printing is ushering in the “third industrial revolution”[1] by eliminating long complex supply chains and opening the door to mass customization over mass production;[2] or that additive manufacturing is a complimentary tool capable of reducing design and development cycles through rapid prototyping and faster design iteration,[3][4] the adoption of 3D printing into an organization is not a light switch event and will take time to prepare for and benefit from.[4]

How Additive Manufacturing is Impacting the Automotive Industry

Additive manufacturing in the automotive industry has been around since the 1990s focusing on rapid prototyping parts during the development cycle.[5] With improvements in cost, materials, printing processes, and printer size,[1][5][6] the adoption within automotive companies has grown rapidly. A decade ago, Ford Motor Company produced only 4,000 prototype parts utilizing 3D printing. This number has exploded to over 100,000 prototypes annually with 3D printing becoming a crucial part of Ford’s development cycle.[7]

With the wide spread adoption of 3D printing, Ford has been able to greatly reduce the time and improve flexibility within its design and development processes. Ellen Lee, Ford’s additive manufacturing research technical leader, estimates the time required to produce prototype parts has reduced by one-tenth due to 3D printing.[7] Traditionally, prototyping would require the design, fabrication, and manufacturing of a single part to be tested and validated.[7] This process traditionally could take half-a-year and cost $500,000 to produce a single design; with 3D printing this process takes days and cost $1,000.[8] In addition, 3D printing removes the need for machine tooling to produce the initial part. Iterative designs also do not require the costly and timely tooling. This allows multiple designs to be fabricated and tested in parallel and within days of the initial design which traditionally takes half a year for a single iteration of part.[7]

How Ford is Approaching Additive Manufacturing

Building an organization with the expertise to build and analyze vehicles which utilize 3D printed parts is not a light switch event. Organizations must prepare their engineering design and materials functions for 3D printing. Component designs and material properties will be dependent on printing processes. Organizations must hire employees to handle the new challenges that arise from additive manufacturing.[4] To prepare for future innovations in additive manufacturing, Ford has been increasing the use of additive manufacturing within its product development cycle. 3D printing has become a crucial piece of Ford’s product development.[7]

Next Steps

With the automotive industry focusing on the next generation of fuel efficient and electric vehicles, additive manufacturing may play a role in reducing vehicle weight and improving fuel economy or battery range.[9] Ford should consider the role additive manufacturing can play in weight reduction, fuel economy, or battery range of a vehicle.

The hype behind 3D printing promises a supply chain revolution and movement away from large national factories.[2] Similar to Ford’s decade long progression in adopting additive manufacturing in its development cycle, Ford could start experimenting with 3D printing in its service organizations. While 3D printing struggles to replace current mass production processes, 3D printing may serve smaller volume vehicles such as older vehicles still on the road today. Ford could introduce 3D printed replacement parts, enabling Ford to develop the expertise it needs for a future supply chain revolution.

In Closing

Ford is poised to transform its development cycle by utilizing additive manufacturing which has reduced development time and increased design flexibility. This transformation is no small feat as the automotive is ingrained with historic knowledge and design. Looking forward, how will Ford further incorporate this new technology and processes into its old wealth of knowledge and products?

(791 Words)

Works Cited

- W.J. Lim, K.Q. Le, Q. Lu, and C.H. Wong. An overview of 3-d printing in manufacturing, aerospace, and automotive industries. IEEE Potentials 35, no. 4 (2016): 18–22.

- Richard A. D’Aveni. 3D Printing will Change the World. Harvard Business Review 91, no. 3 (March 2013): 34.

- Holwef. The limits of 3D printing. Harvard Business Review Digital Articles (June 23, 2015).

- B. Roca et al., Getting past the hype about 3-D printing. MIT Sloan Management Review 58, no. 3 (Spring 2017): 57–62.

- Global 3D Printing Materials Market in Automotive Transportation, Forecast to 2024. Frost & Sullivan. Industry Research Analysis MD5C. Chemicals, Materials & Foods. (February 2018)

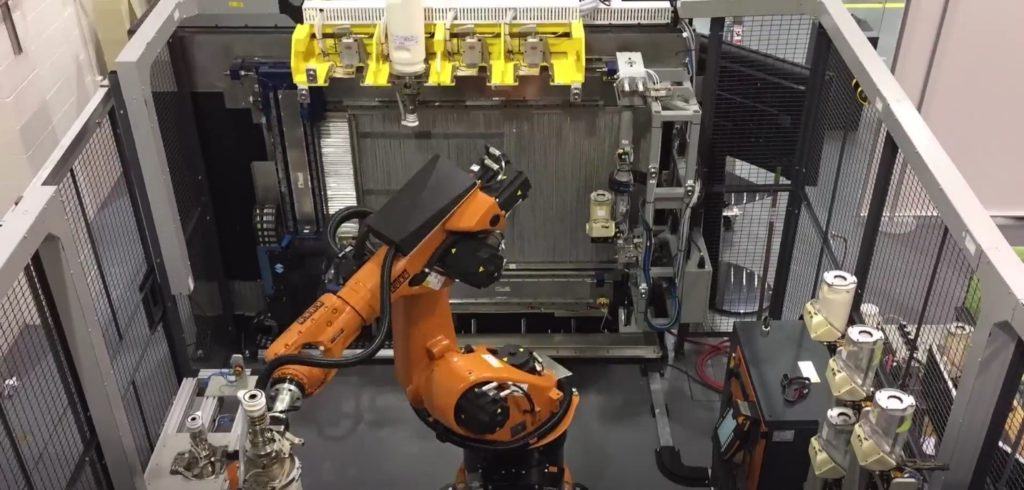

- Sam Abuelsamid. Ford Starts Pilot Testing Stratasys Infinite Build 3d Printer. (March 2017) https://www.forbes.com/sites/samabuelsamid/2017/03/06/ford-starts-pilot-testing-stratasys-infinite-build-3d-printer/#7a606f483710

- Lucas Mearian. 3D printing is now entrenched at Ford. CIO: Framingham (August 2017)

- Roy Raymer. Building in the Automotive Sandbox. Ford Motor Company. (Accessed: November 2018). https://corporate.ford.com/innovation/building-in-the-automotive-sandbox.html

- Rachel England. General Motors is 3D printing parts to make EVs more efficient. (May 2017). https://www.engadget.com/2018/05/03/general-motors-3d-printing-parts-evs-efficient/?ncid=txtlnkusaolp00000616

- Ford Tests Large Scale 3D Printer. Ford Motor Company. Press Release. (March 2017). https://media.ford.com/content/fordmedia/fna/us/en/news/2017/03/06/ford-tests-large-scale-3d-printing.html

Great post! Coming from the automotive industry and having experienced many product development processes, I think that the potential benefits that additive manufacturing can bring to the industry is huge.

I totally agree with you about the cost and time savings in tooling and prototyping. I had probably 20 workshops with vehicle parts designers and engineers to test the marketability of the vehicle design components such as the front bumper. Many times, we complied that we did not have the part to touch and feel and assess its potential in a more customer centric way. The reason was mainly how expensive it was to develop a prototype to just test customer acceptance.

Now many OEMs are shifting efforts and investing heavily in 3D printed parts. However, I am quite concerned about the scalability that this technology has beyond the product development process. Implementing 3D printed technology to produce actual parts to be installed in a vehicle, would require a completely redesign of the production process. For instance, the throughput time of a 3D printed panel is higher than the corresponding of a conventional injection part once the tooling is built.

So I think the potential is promising to the product development phase but in the manufacturing process, there is still work to do for the OEMs to adapt its manufacturing process to the new technology. One possible solutions encountered by startups such as Local Motors is using microfactories, which are a physical operating space, designed for rapid prototyping, modular experimentation, and small-batch manufacturing of products. For example, microfactories can make weather-specific vehicles such as all-wheel-drive for snowy locations using additive manufacturing to rapid adapt to customers demand. But how scalable in terms of volume is that? How many micromanufacturing facilities are needed to compete with an automotive giant?

Thanks for sharing this interesting article. It seems pretty compelling that 3D printing has opened up a world of possibilities around the cheap, fast development of prototypes. However, do you think there may be any risks of moving to a much cheaper/faster additive manufacturing process versus the historically more deliberate, expensive process for prototyping? For example, might the hurdle of requiring large initial investments helped the funnel to ensure that only the best ideas have time spent on them? This reminds me a bit of the IDEO case where they started with a super wide funnel before focusing on the most relevant/tactical ideas; seemed like the case was split at the time so I wonder if there are potential negatives here as well. Thanks again!

Awesome! Using 3D printing for tooling is definitely appealing. This allows the auto companies to use the same materials and processes they are accustom to in their production designs. Using 3D printed designs directly in products could be more troublesome though. Auto companies typically require each and every material-set used in a vehicle to go through an intense qualification and accelerated lifetime analysis. Unfortunately, most 3D printed products come with some compromise in strength vs. a bulk material. For instance, I’ve heard UV-curable materials are basically ruled out completely by these manufacturers because they tend to become brittle with continued exposure to sun. This means they won’t work with SLA processes.