Nike’s Stance on 3D Printing: Just Do It

Nike has dominated the global shoe and apparel market for decades. However, a period of revenue stagnation has led the brand to develop a new corporate initiative and strategy that will rely on investments in 3D printing.

3D Printing’s Role in Nike’s Strategic Growth

In 2017, global shoe and apparel behemoth, Nike, unveiled a new corporate initiative, titled the Consumer Direct Offense, meant to generate the next wave of long-term company growth and profitability. The driving force of the Consumer Direct Offense is Nike’s Triple Double strategy, which includes three pillars: 2X Innovation, 2X Speed and 2X Direct [10]. 3D printing appears to be at the core of the first two pillars.

2X Innovation is Nike’s goal to “double the cadence and impact of innovation”, and 2X Speed represents the need to “double speed to market by reducing the average product creation timeline by over 50 percent” [9]. Additive manufacturing accomplishes both objectives by facilitating the “rapid prototyping” process, allowing Nike’s product development teams to create customized shoe prototypes in a matter of hours, instead of months through traditional methods [1].

The Technology Behind Nike’s Innovation

Nike first began experimenting with 3D printing in 2013 when it released the Nike Vapor Laser Talon; touted as the “first-ever football cleat built using 3D printing technology” [7]. However, the company did not fully invest in additive manufacturing until 2016 through a partnership with information technology firm HP [1]. According to Nike’s President of Innovation, Tom Clarke: “[We] are excited to partner with HP to accelerate and scale our existing capabilities as we continue to explore new ways to manufacture performance products to help athletes reach their full potential” [1].

That year, Nike developed a customized track spike, the Nike Zoom Superfly Flyknit, by rapid prototyping for American sprinter Allyson Felix before the Rio 2016 Olympics. At Nike, collaborating with high-profile professional athletes for product development is paramount. As Mark Parker, Nike’s CEO, explains: “Always, always, the elite athlete still leads our design. What we learn from them is who we are” [6]. 3D printing will define the product development for the next generation of elite Nike products.

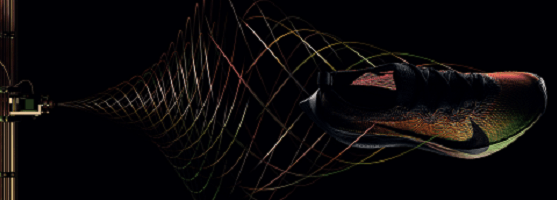

The expanded investment in 3D printing has already proven beneficial for Nike. In Spring 2018, Nike developed the Nike Flyprint – the first shoe in performance footwear with a 3D-printed textile upper [11]. In collaboration with world-class marathoner, Eliud Kipchoge, the Nike Flyprint translated complex athlete performance data from the Nike Sports Research Lab into prototype iterations with unprecedented quickness and precision [11].

https://www.youtube.com/watch?v=RFW35vTTGQI

What’s Next?

Monetizing their investments in additive manufacturing is a short and medium-term objective for Nike. The brand recently publicized they are preparing to commercialize their 3D-printed products like never before with the global release of the Zoom VaporFly Elite Flyprint 3D in Q1 of 2019 [4]. Nike is making a big bet that their aspirational consumers will value the additional product benefits 3D printing introduces; such as being the lightest and most breathable performance shoes Nike has ever produced. Furthermore, 3D printing will continue to be a focus of Nike due to its pivotal role in accomplishing the brand’s Consumer Direct Offense and Triple Double strategy, which the company projects to drive sustained high-single digit revenue growth over the next five years [9].

Of course, Nike’s business doesn’t operate in isolation. Footwear competitors, Adidas, New Balance and Under Armour are all leveraging 3D printing for product development and are in various stages of commercializing 3D printed shoe lines, with Adidas widely considered the industry leader in this area of innovation [2]. Nike must take immediate steps to avoid falling too far behind their rivals.

Recommendations and Questions

First, I recommend that Nike significantly expands its 3D printing prototyping to incorporate a wider roster of elite athlete endorsers. More mainstream athletes should be involved with developing customized shoes to address their unique performance challenges. If a Nike endorsee like Cristiano Ronaldo were to have a 3D-printed shoe there would be an incredible buzz around the product.

Additionally, Nike should invest in promoting these 3D-printed products through advertisements, branded content and other forms of storytelling to attract and engage with consumers. Creating value through marketing promotions is undoubtedly Nike’s strength. Eliud Kipchoge, the marathoner that helped develop the original Nike Flyprint, advocated that the shoe was the lightest he’d ever worn and felt the shoe would give him an advantage in the 2018 London Marathon [3]. Kipchoge went on to win the marathon while wearing Nike’s innovative 3D-printed shoes. These are the stories Nike needs to authentically tell.

Nevertheless, there are critical questions outstanding that will impact Nike’s ability to maximize 3D printing. Will 3D printing factor into Nike’s third element of the Triple Double strategy: 2X Direct? This is the brand’s direct-to-consumer and customization initiative. According to a 2017 retail consumer survey, 95% of shoppers are looking forward to purchasing products created through 3D printing [5]. However, Nike must also answer whether additive manufacturing can be scaled enough to satisfy consumer demand? Despite these uncertainties, 3D printing projects to be central to Nike’s strategy to grow its shoe wear and apparel empire.

Word count: 798

References

[1] “At Nike the Future is Faster, and it’s 3D.” Nike News, May 17, 2016. https://news.nike.com/news/nike-hp-3d-printing.

[2] Bain, Marc. “Adidas is kicking off the era of 3D-printed sneaker production with the Futurecraft 4D”. Quartz, April 17, 2017. https://qz.com/quartzy/1254503/nike-just-debuted-flyprint-a-3d-printed-stretchy-customizable-sneaker-upper/.

[3] “How Eliud Kipchoge Helped Perfect Nike’s 3D Printing Process For Uppers.” April 17, 2018. https://news.nike.com/news/eliud-kipchoge-3d-printed-nike-zoom-vaporfly-elite-flyprint.

[4] Iftikhar, Umair. “Nike’s 3D Printed Elite Shoe Preparing for a Wider Release.” 3D Printing Industry, November 1, 2018. https://3dprintingindustry.com/news/nikes-3d-printed-elite-shoe-preparing-for-a-wider-release-142527/.

[5] “Interactions Releases ‘What Shoppers Want from Retail Technology’ Survey.” Interactions Marketing, May 18, 2017. https://www.interactionsmarketing.com/press-releases/interactions-releases-shoppers-want-retail-technology-survey/.

[6] Johnson, Ryan and Elie Ofek. “Nike Football: World Cup 2010 South Africa.” Page 3. Harvard Business School Publishing. January 17, 2013.

[7] “Nike debuts first-ever football cleat built using 3D printing technology.” Nike News, February 24, 2013. https://news.nike.com/news/nike-debuts-first-ever-football-cleat-built-using-3d-printing-technology.

[8] “NIKE, Inc. Announces New Consumer Direct Offense: A Faster Pipeline to Serve Consumers Personally, At Scale.” Nike News, June 15, 2017. https://news.nike.com/news/nike-consumer-direct-offense.

[9] “NIKE, Inc. is Accelerating a Consumer-Led Transformation to Ignite Its Next Phase of Long-Term Growth.” October 25, 2017. https://news.nike.com/news/nike-inc-is-accelerating-a-consumer-led-transformation-to-ignite-its-next-phase-of-long-term-growth.

[10] Nike, Inc. November 5, 2018. 2018 10-K form. Retrieved from http://d18rn0p25nwr6d.cloudfront.net/CIK-0000320187/d8ec8664-332c-462d-9002-6e95c7fe90ce.pdf.

[11] “What is Nike Flyprint?” Nike News, April 17, 2018. https://news.nike.com/news/nike-flyprint-3d-printed-textile.

Great article on how Nike is utilizing 3D printing — well done! In response to your question regarding how 3D printing will contribute towards Nike’s third goal of 2x direct, as you suggest, I feel that this technology is core to that goal and will enable Nike to develop highly customized shoes at a great scale. In an ideal world, as the costs of 3D printing continue to decrease, the ability to simply tweak a software or input a customers’ desired size & color combination, rather than retooling an entire machine, will eventually enable Nike to react quickly to customer orders and delight customers at a speedy product turn-around. This level of speedy customization would be truly incredible, thrilling Nike fans around the world!

Really interesting article — you point out great benefits 3D printing could offer Nike, and I agree with all your recommendations. It’s clear that 3D printing could offer many synergies to Nike’s process of creating products and partnering with athletes to iterate and improve upon them. I wonder, however, if this trend might democratize product design and iteration, therefore decreasing the company’s reliance on athletes as product visionaries, and ultimately incurring a downstream impact on the brand as a whole? For instance, in a world where consumers can walk into a Nike store and design/print their own shoe, does the Nike brand slowly lose its “stamp of approval” by major athletes? Maintaining this balance in a world where additive manufacturing starts to become the norm might be challenging.

Nike’s use of 3D printing in its rapid prototyping process is fascinating and makes a lot of sense for executing upon the two pillars of the “Triple Double” strategy that you mention, 2X Innovation and 2X Speed. By speeding up the prototyping process, Nike can experiment and bring innovative products to market much faster. But I think you pose a very important question at the end of your post — to what extent can Nike really utilize this new technology to execute upon the 2X Direct promise for consumers?

Given current constraints on additive manufacturing in terms of cost and scale-ability, Nike may risk disillusioning customers by marketing this technology too quickly and causing consumer expectations to exceed reality. Nike does want to showcase how it is innovating with 3D printing in certain ways (e.g., prototyping and creating custom shoes for elite athletes), but the company has to strike a delicate balance between creating excitement among loyal customers and creating unrealistic expectations in the short term.

This is a really well-written article on how Nike is incorporating 3D printing into its processes and production. I think that there doesn’t seem to be a reason why additive manufacturing cannot be scaled enough to satisfy consumer demand for Nike, and so Nike should further invest in the technology so as to make progress against its strategy to grow as quickly as it lays out in its direct-to-consumer and customization initiative. I really like your idea of getting mainstream endorsers like famous soccer players to wear the 3D printed shoes to create buzz around the proudct – I think you could also combine social media to generate a lot of publicity and widespread knowledge.

Great article! I agree that additive manufacturing for Nike’s shoes is a logical evolution in Nike’s strategy that hits all three pillars of 2X Innovation, 2X Speed and 2X Direct and anticipates the direction of the market. However, to expand on ABP’s democratization comment, I fear that the gains derived from this 3D printing technology will result in short term gains and long term losses. As 3D printing becomes more ubiquitous, it will become harder and harder for Nike to protect the IP of their designs, exposing them to potential generics sold at half price with the same quality. We have already seen the risks of 3D printing with generic, plastic firearm designs.

To mitigate this risk, I would recommend that Nike focus substantial R&D on developing a hard-to-reproduce thread or printing material that can protect their design. Nike would also need to invest in Coca Cola levels of secrecy surrounding both their 3D printing design and thread manufacturing process. If Nike is unable to protect this IP, they run the risk of innovating themselves out of existence.

It surprises me that Nike hasn’t been more vocal about its victories in this space. That seems to be their MO – and the fact that Eliud Kipchoge won the London Marathon wearing their 3D printed shoes almost writes it’s own commercial! Frankly I’m surprised I hadn’t even heard about that. Perhaps for the moment Nike is being conservative about their technology for fear of creating TOO much consumer demand off the bat and, as you mention, struggling to scale. What I’m curious to know is how much of the current production process can be replaced by 3D printing. Rapid prototyping is an obvious benefit, and printing the Flyknit upper seems like another step forward. What happens when the entire product can be created by a 3D printer? Will Nike fully automate their production process? As the price of 3D printing declines, will their cost savings be passed on to the consumer? Is it feasibly that some day soon, I have my own 3D printer at home and buying a Nike shoe simply requires that I purchase and download a digital blueprint to send to my own printer?

Great article. Incredible how 3D printing is a perfect fit for Nike product development process, increasing speed of iterations between Nike Lab and Athletes. To the question asked, Nike can certainly leverage its developing 3D technology in order to perform better on the 2X Direct pillar. In my perception one of the sub-components of reaching an effective direct-to-customer channel is also by offering customization and that’s how 3D technology can be certainly helpful in the future. Since this technology might still face some problems with scaling at first, delivering highly customized products for clients willing to pay a premium for it might be a great strategy to be recognized as the 3D technology Sports brand and Start experimenting new approaches for commercialization of this new technology.

Thanks for the interesting read on Nike’s push for additive manufacturing in its shoe design. On your last question about the scalability of the technology, I believe that one potential solution could reveal itself over time. I am of the opinion that the evolution of additive manufacturing will follow a similar path to that of the computer. Currently the technology is limited to large corporations and hobbyists. Over time, the proliferation will increase and many homes will have their own machines. In this world, Nike will provide the technology, materials, and design, while manufacturing will be decentralized. It will be interesting to see!

Interesting piece—thanks for sharing! The two main challenges I see with leveraging additive manufacturing for growth at Nike are 1) competition, and 2) scalability. It seems that Nike’s main competitors are aggressively leaning on 3-D printed shoes as a core component of their innovation strategies, making this technology application less of an opportunity for Nike, and more of a necessary investment to keep up with the competition. That said, it seems that one solution may address both of these obstacles to growth. Nike needs to get more personal with its approach if it hopes to continue its market dominance in the space and reach customers directly—rounding out its triple double strategy.

To do this, Nike should leverage its large store footprint to push for personally customized shoes fit to the needs of each individual. This follows closely with how Dr. Scholl’s used its fit-finder kiosks to differentiate from other orthotic options and capture market attention. Furthermore, Nike making individual shoes for each customer would enable the company to build more of an emotional connection between customers and products. Beyond having a better product fitting each individual’s needs, consumers customizing colors, patterns, and textures will both yield a premium price and leave customers with positive feelings towards Nike for future purchases. More users for its machines would also reduce unit costs, making the prices more affordable and accessible for buyers. This also fits with Nike’s promotional push to “Just Do It” and be yourself.

I am fully in support of Nike doubling down on its additive manufacturing strategy, and I feel its imperative to do so in today’s age when its largest competitors are way ahead of the curve. To your question on how this aligns with Nike’s “2X Direct” strategy, I think it could be a way to get closer to the customer. Using its large store footprint, Nike could use 3D printing to offer customized shoes to the customer who desires, thereby increasing the personal touch and brand loyalty.

This needs to be supported with telling the story properly. We saw in the Nike case in marketing how it does a great job of using elite athletes’ opinion to develop the product and become the champions of their product. Apart from that, it could use this new innovative technology to tell its most loyal customers how they could now have their own requirements perfectly fit into one shoe!

Though I believe this can give them a competitive edge, I don’t see this scaling up significantly in the coming years, as individualized products would also mean higher costs and hence prices for the consumer. I wonder if we could reach a stage where 3D printing for shoes in stores becomes the norm and we no longer have mass production in factories.

Nike can certainly address its 3rd pillar of 2x direct with 3D printing both in the short term and long term. We have seen the success of Nike ID, which has already increased the firm’s direct to consumer sales both through direct sales of Nike ID products and through indirect sales to customers attracted to the website by the ID products. I think that 3D printed shoes and apparel could have the same impact in the short term, while commanding a premium. In the long-term, as 3D printing costs decrease and the technology can be scaled, customized shoes will be able to be created to order for a larger market, which will not only increase direct sales, but will lower inventory costs, a huge consideration for manufacturers and retailers. Additionally, if Nike could incorporate biometric scanning or algorithms that use a few measurements to predict fit, it could further increase its direct to consumer sales.

As expected, Nike is doing incredible work at the forefront of the industry by incorporating 3D printing into their manufacturing practices. I was in Rio at the Nike lab when they put these shoes out as prototypes, showcasing the direction they are going. For the skiers out there, much of the quality of a ski boot is tied up in getting a great bootfitter to form and mold the boot and custom insoles perfectly to the skiers foot. They also align the boot to ensure the skier’s joints stack up perfectly when they are skiing to give them more control over the skis. I mention this because it seems very relevant, for example, among runners. Runners put an immense amount of effort into finding a shoe that fits their foot with arch support, toe box, heel fit, pronate and supinate, etc. It seems like Nike could move into the custom shoe market that fits the runner’s foot very well by scaling this technology and finding a way to do DTC work after scanning a person’s foot in the store. Running stores already do things like this by watching runners run in different shoes, and this would be a big hit among distance runners everywhere, not to mention the other potential impacts in other sports.

Scaling additive manufacturing does have a lot of challenges today. The cost is high and the demand is low to tap on utilities of scale. But I think over time with advance in technology , much like other industries, the cost of additive manufacturing will lower, creating more demand for these products and it return tapping on utilities of scale. But till then companies like NIKE should keep promoting products from additive manufacturing to create the buzz around this and turn this into demand when the time comes.

This is great, Melcolm! For me, the biggest question that the use of AM at Nike raises is, “How much to consumers care about how their shoes are manufactured?” It is interesting to me that Nike has chosen to make the fact that shoes are 3-D printed part of the marketing for those shoes; I’d be very curious to see the consumer research around the value a customer places on this production process. Assuming Nike could achieve pretty similar product attributes through traditional manufacturing techniques, my instinct would tell me that for the majority of buyers, they are simply looking for the best shoe at the lowest price, and aren’t concerned with manufacturing.

The important business implication of this question, in my mind, is that to the extent customers are agnostic to manufacturing process, Nike could avoid the capital intensive investment in the 3-D printing in the short term, and switch to mass Additive Manufacturing once other companies (shoe companies or otherwise) have created enough scale demand in the market such that AM technologies are economical for mass production.

Very interesting article and cool video. It’s amazing to see that the Zoom VaporFly Elite Flyprint 3D is not only producing at a fraction of the variable costs but also delivering great qualities in terms of weight and breathability.

In response to your recommendations, I actually hold a contrarian view that as any of these new technologies scales in adoption, the technology itself, i.e. 3D printing, should not be promoted as part of the product highlights. Consumers are buying the products because they are the best quality products, regardless of the backend technology used for making the product. Merchants around the world advertise their products as “hand-crafted with care” and are able to price at a premium based on the human labor required, or lack automation, whereas for Nike, when they can sell the best quality product for half the price, that’s when they are successful.

Your question regarding Nike being able to scale to sufficiently meet customer demand is fascinating to me for two reasons.

First, most industry experts still believe that additive manufacturing’s sweet spot is producing a small number of highly complex products more cost effectively than the traditional manufacturer. As such, I question whether the investment community will stand behind companies trying to develop technology that prints already low cost items, especially as AM as an industry continues to gain steam and more VC money pours into ‘critical service parts’. On this, I am more pessimistic. I do not believe Nike will be able to properly scale to supplant traditional manufacturing for their lower cost items.

I do see an opportunity for Nike to use 3D printing to solve supply chain problems, however. In a world where UPS, Amazon, and other logistics players are using 3D printers as an alternative for traditional distribution in more remote parts of the country / world, I see Nike being able to sell their IP to these companies to operate, while they earn their usual margin.

Very interesting use of additive manufacturing in the footwear industry. Nike is quite unique in its ability to charge exorbitant premiums for its hottest shoes – whether Jordan’s or Kobe’s or anything else. Judging by the lines out the door of Niketown’s whenever there is a limited release event, its clear that demand for the most unique Nike products significantly outstrips supply. I think additive manufacturing poses the chance to extract a lot more value out of the marketplace, but it has to be balanced with the political and social optics of potentially displacing existing workers. To the extent that additive manufacturing is also additive to human labor, we can cheer it as a success. Anything less should be a cause for concern.

Melcom Ruffin… I’ve always hated you for your skill at adeptly referencing learnings from past cases in other classes. Most of all I hate how interesting this development in Nike’s production line is and how it could both create significant cost savings for them as a company while maintaining the brand’s reputation through the steps you suggested. This fits particularly well with their history of innovation and, as much as I hate to admit it, I agree that pairing it with high profile endorsements would go a long way to making this well selling product. If anything it actually seems common sensical for them to do this. Damn you and your insightful insights Melcom Ruffin… Damn you.

I see 3D printing as being beneficial to Nike from a marketing perspective, especially if they can capitalize on first-mover advantage! Consumers have traditionally valued Nike as an innovator in shoe technologies that improve performance, so people will have significant reason to believe that Nike’s use of 3D printing offers a higher performance, lighter shoe. Given the survey results you cited and increasing buzz about 3D printing, I imagine that this will be a huge market for Nike. (I want to buy a pair!)

I do worry about their ability to scale given the controversy about whether 3D printing is truly prepared for mass production. Typically, 3D printing is employed when complex processes cannot be completed successfully or quickly enough otherwise, which is not the case for Nike shoes. I therefore wonder if Nike will be able to appropriately lower their costs associated with 3D printing to make mass production sustainable.

Super fascinating article, Melcolm! Really enjoyed reading about Nike’s move toward 3D printing to boost recent stagnation in innovations and revenues.

I think your recommendations are absolutely right for the direction Nike should go. They have been one of the world’s most iconic brands for partnering with legends across sports and showcasing a marriage between high performance and quality products and authentic stories regarding aspiring to greatness and enjoyment through sport. To leverage 3D printing for innovations, it is key that they partner with elite athletes and promote their stories and experiences with said innovations. Kipchoge’s win is an incredible story to tell with that! Additionally, to have a consumer base of 95% looking forward to innovations such as this, they should push this story. That said, your concerns would be mine as well regarding the possibility to scale. Would 3D printing be able to satisfy consumer demand? And if a shoe is marketed as being a 3D print production but really was just prototyped through it, would that erode a customer’s trust? Really interesting article!

Other commenters have of course pointed out the constraints around mass production. I wonder if there is a product strategy that captures extra value from limited production. This seems like a fairly obvious play for sneakers (thinking Yeezys) where rarity commands extra value. I would imagine that this is the strategy that Adidas is taking. How can Nike stay one step ahead of this strategic move? I can see the product strategy going one of two directions a. charging a premium for high levels of user customization and offering this customization en masse and very close to the consumer, or b. making it economical to make more frequent small runs of highly exclusive endorsed sneakers that have some “ephemerality” to them – meaning they will never be produced again. My bet is that Adidas will go for strategy a and Nike will go for strategy b.

This was a great read Melcolm! I’m curious about what operational changes Nike needs to make to scale 3-d printing to mass production and how these changes would affect its cost structure. Nike currently manufacturers a lot of its products using overseas, low cost labor. While 3-d printing has the potential to reduce manufacturing costs by reducing waste, increasing quality / uniformity and increasing speed / output rate, the technology is still pretty nascent and would require a significant capital outlay to implement on a large scale. Would the cost savings from reduced labor outweigh the increase in capital costs? How many years away from this scenario are we? Or could Nike command a high enough price for 3-d printed shoes to make the same profit margin on the higher cost base associated with 3d printing?

Mr. Ruffin, thank you for posting your article. Reading the Nike shared with us by our Marketing professor I was very surprised by the time to market Nike professed to have per product. Three years! “Just doing it” seemed flat. With your post, I know appreciate that Nike is aware and “Just doing business” with some thought behind it. I appreciate your explanation on how 3D printing will bring faster prototyping and testing, enabling them to shorten the time to market.

Furthermore, I agree with you that Nike should double down on 3D printing and start promoting its bet. I, Bruce Willis, having been born in Germany to a German mother, am very aware of the leaps Adidas has been doing in 3D printing, and had the a priori conception that Nike is a laggard in this area. Nike is still in time to reverse the idea that is losing its technological edge. I hope, as an American patriot, that Nike leadership listens to you.

Your article has also given me food for thought, specifically in two areas. First, finding shoes that fit just perfect is rare to find. I would be interested in knowing if Nike is exploring or already developing ways to print shoes specific to each customer. Second, understanding that all main players are moving into 3D printing, I dwell on what can Nike do to differentiate itself. Are there new possibilities apart from doing lighter shows? What is the next frontier?

Very interesting read!

The first thought that comes to mind is what would happen to the human capital that Nike employs, especially in emerging countries. I imagine once shoes are produced at scale via 3-D printing, there will be less human labor utilized – across the industry. Would this be transferable to the apparel industry?

Agree with the question whether economies of scale can be achieved with the level of customization proposed. Interesting to think about this process. How many 3-D printers will be required at scale? What would be the lead time from order to delivery and what would be the impact on price. I think as consumers, we may experience severe indecision, given all the choices.

On a separate note and I’m not sure if you came across this but is there ability to implement smart technologies in the shoes of athletes to understand the nuanced aspects of movement and speed? Kind of like a Fitbit in a shoe?

Great article. I like how you tie the 3D printing aspect to Nike’s Double Triple strategy. That said, while I appreciate the first two pillars (Innovation and Speed), I do not agree that Nike’s current approach to 3D printing will solve the last pillar (Direct-to-consumer) for 2 reasons:

Firstly, the company heavily relies on famous athletes to drive the design of these 3D printed shoes. This is supported by Tom Clarke (President of Nike Innovation)’s quote: “At Nike we innovate for the world’s best athletes” [1]. For the average customers, there is little evidence to support that Nike is developing infrastructures to let these average customers participate in designing their own shoes. By contrast, one of Nike’s biggest competitors, Adidas, is already considering putting treadmills in their retail stores to collect biometric data and help their customers instantly get a 3D printed running shoes [2].

Secondly, despite the fact that 95% customers want to try the product, the product’s high price tag ($700 compared to Adidas’s $300 3D printed shoes) can alienate a lot of them. If the pricing strategy is not executed well, Nike runs the risk of their 3D printing getting lumped in with their self-lacing Hyperadapt which drew ire from the public from the high price tag [1][3].

[1] Alec Banks, “Who Is Winning the 3D Printing Battle in Footwear and Why?” Highsnobiety, December 16, 2016

https://www.highsnobiety.com/2016/12/15/3d-printed-shoes-nike-adidas/, accessed November 15, 2018

[2] Adidas Group, “Adidas Breaks the Mould with 3D-printed Performance Footwear,” October 07, 2015

https://www.adidas-group.com/en/media/news-archive/press-releases/2015/adidas-breaks-mould-3d-printed-performance-footwear/, accessed November 15, 2018

[3] Daniel Pearson, “Nike’s Self-lacing Hyperadapt 1.0 Is Releasing Next Month & Will Cost $720,” November 14, 2016,

https://www.highsnobiety.com/2016/11/14/nike-hyperadapt-1-0-price-release-date/, accessed November 15, 2018