Ministry of Supply: Using 3D Printing and AI in clothing

“We started Ministry of Supply to solve the problems of stiff, high-maintenance dress clothes by engineering high-performing, comfortable apparel” [1]

History of Ministry of Supply

Many industries have been disrupted by the new technologies of additive manufacturing and machine learning. For the most part, the fashion and clothing industries have not seen this disruption. Ministry of Supply is embracing additive manufacturing and machine learning to create product improvements in an industry that could avoid doing so at the current moment. Ministry of Supply was founded by MIT alums with the goal of providing high-tech and comfortable clothing that could also be professional and stylish. Designed in appearance for being in the office, these clothes are “breathable, waterproof, moisture wicking, and odor controlling, making for a streetwear-meets-sportswear hybrid”. [2] To prove just how comfortable they are, one of their co-founders even ran a marathon in a Ministry of Supply suit.

https://www.instagram.com/p/-979qPR7nS/?utm_source=ig_embed[2]

Use of 3D Printing and AI

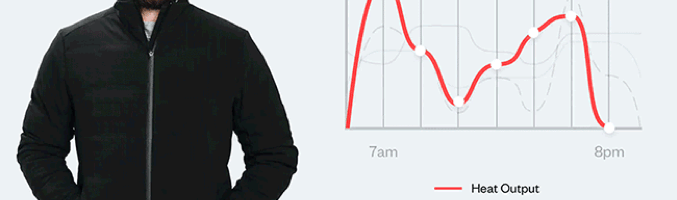

As described by Ministry of Supply their 3D printed items, ranging from dresses to blazers to crew-necks are constructed with technology similar to 3D printing which “uses seamless design to create defined, sculpted shape with zero bulk that moves freely with your body”. [3] People are different shapes, so Ministry of Supply is working to use 3D printing technology to help consumers get clothes that were designed for their bodies. In addition to designing the shape, these 3D printed clothing options also take into account which areas of the item have the most strain on them and factor this into the design. [4] Beyond enhancing the current sizing and fit issues, 3D printed clothes offer a major sustainability benefit that traditional tailoring can’t match. The printing process for Ministry of Supply’s 3D printed items create close to no waste. Compared to the typical 30% waste that’s generated from traditional techniques, this advancement offers major improvements by utilizing an additive process rather than subtractive. [5] Furthermore, another sustainability benefit comes from the products simply being more durable than traditional fabrics. There are no seams in 3D printed clothing since it’s created through an additive process. The lack of seams helps in the way of durability as it reduces rips and tears. [4] Expected to be available in November 2018, Ministry of Supply’s Intelligent Heat Jacket uses AI and Machine learning to provide an optimal user experience. A “smart thermostat” within the jacket reacts to its environment (your surroundings and your body) and can adjust by providing up to 10 Watts of heat. [6] The jacket is able to seamlessly heat up based on your needs by using three carbon fiber heating devices which are each less than 1 millimeter thick. This jacket also offers an app and voice control functionality as well as wireless phone charging. [7][6]

Concerns related to 3D Printing and AI

The use of 3D printing and AI in Ministry of Supply’s products creates concerns around price point and employment. These items currently come at a higher price point than many of their competitor’s goods. As technological advancements improve and the product proves itself, this concern may dissipate. It certainly hasn’t slowed the company down thus far. Using 3D printing to create clothes eliminated the need to lay out fabric, cut a pattern, and sew the item. [4] This could have an impact on employment for the production side of clothing throughout the industry if the trend grows. Additionally, Ministry of Supply does face a risk of using technological advancements in an industry that hasn’t placed a focus on that need. For example, the enhanced fabrics used during the additive process may not hold the same esteem as traditional fabrics.

Recommendations

I would recommend that Ministry of Supply continue to use process improvement and product design megatrends in their products. This is unique for the industry which poses its own set of risks, however by embracing these technologies Ministry of Supply has a chance differentiate themselves within the market while providing a useful product.

Open Questions

The questions that I have for Ministry of Supply are around their innovation and use of new technologies. What does this company need to do while using innovative technologies to remain an accessible and practical option for consumers? What further innovations can be made to their existing products using machine learning?

(725 words)

[1] Ministry of Supply. “About Us.” Performance Professional Clothing for the Workday | Ministry of Supply, ministryofsupply.com/pages/about-us.

[2] Ducharme, Jamie. “This Guy Ran a Half Marathon in a Ministry of Supply Suit.” Boston Magazine, Boston Magazine, 9 Sept. 2016, www.bostonmagazine.com/health/2016/01/14/ministry-of-supply-marathon/.

[3] Ministry of Supply. “3D Print Knit Sweater”. https://ministryofsupply.com/products/3d-print-knit-sweater-dress-navy

[4] Leighton, Mara. “A Clothing Startup Founded by MIT Grads Is Using 3D Printing to Make Better, More Sustainable Clothes.” Business Insider, Business Insider, 6 Sept. 2017, www.businessinsider.com/ministry-of-supply-3d-printed-knits.

[5] Ministry of Supply. “Sustainability”. https://ministryofsupply.com/pages/sustainability

[6] Ministry of Supply. “Mercury Intelligent Heated Jacket”. https://ministryofsupply.com/products/mens-mercury-intelligent-heated-jacket-black

[7] Black, Erin. “This Self-Heating Jacket Knows How Cold You Are and Adjusts Accordingly.” CNBC, CNBC, 8 Mar. 2018, www.cnbc.com/2018/03/07/ministry-of-supply-self-heating-jacket-was-designed-by-mit-alumni.html.

I love this article because I a huge fan of MoS. I have a fair amount of their clothing and find it worth the higher price point because of the comfort and convenience. The most amazing thing is how robust the clothing is, whether while running a half marathon (or running with my partner in scorching Florida heat wearing a button down and khakis), or throwing those same clothes in the washer with no special concern. While I agree that their price point needs to be lowered in order to appeal to a wider market, I think they have a great opportunity with 3D printing because it can allow them to adopt Just-In-Time philosophies with their production. It also means that they should be able to produce clothing from older lines, without the same concern of economies of scale that a normal clothing maker might have, meaning you could just keep re-ordering a pair of pants that you love how they fit, and you bought a decade ago. I will not that I say, “should”, because my own experience is that they don’t keep older lines of their clothing accessible.

The last thing I would like to ramble about is that they have actually had the problem that some of their innovations have been too advanced for users, specifically they had non-traditional buttons on pants. They no longer include those buttons because (having talked to people at MoS about this) consumers kept using them incorrectly and tearing the buttons out. I think their biggest problem is that their value-add is their innovation, but their innovation is sometimes too far ahead for their market.

Thanks for sharing this article about MoS. It is my understanding that this company is on the cutting edge of this technology in the fashion sector. You’ve clearly laid out some of the operational benefits of using additive manufacturing and machine learning such as reduced waste and optimized user experience. I think one of the issues of remaining accessible and practical for their consumers is their price point (which you mentioned) as well as the innovation itself.

I don’t know enough about the company to say what they should or shouldn’t do, however, I think they find themselves in a dichotomous situation in terms of their innovation. I believe a portion of their customers explicitly seek out MoS due to their cutting edge innovation and use of machine learning and will always want them to continue pushing their innovation as far as possible. However, their clothing needs to be similar enough in use and treatment to normal, every day clothing for the broader market of consumers to be interested and find it practical, perhaps putting pressure on MoS to rein in its innovation to reach the mass market.

You raise some fantastic points in this article and it has me wondering if MoS is viewed as an innovation company that sells clothing or a clothing company that uses innovation and how that might influence their strategy moving forward.

This is so cool! I love the idea of revolutionizing the fashion industry and clothing production model using innovation. As you pointed out, this creates a clearly superior product. In addition to that, it also reduces the need for manual labour. The production process for clothing has always struck me as one of the most archaic. A picture of hundreds of workers sitting in front of sewing machines would have represented a clothing plant in the 1950s, and would still accurately represent a clothing plant today. This is pushing the production process further and further down the labour pay spectrum into arguably predatory areas. Howerever, I could see push back from large textile labour unions to protect the jobs of their workers. However, I expect this to be far into the future as it should take a long time before costs of this production method become low enough to trickle into that labour spectrum.

To address your question on scalability, I think this industry needs to take an Amazon approach: operate at a loss and use external funding until you reach enough scale to make the unit economics work. If this company can successfully do this, they could revolutionize an antiquated industry.

Thanks for sharing the post TH. Facebook ads of MoS have started to appear in my news feed that up until now I completely ignored. With your post now, I may become a customer.

This new-found credibility comes because of how you laid out the benefits of 3D printing in the apparel industry. Two areas stand out for me.

First, I, Bruce Willis, have a top-notch body form, but given my enormous muscles I understand the difficulty of finding clothes that just fit perfectly. Tall skinny colleagues (e.g., Eliot) in your section might suffer from the same issue, where a medium size might just be bit short, and a large size might make them feel as a dad with no taste for fashion. MoS will start a revolution if it is able to make clothes designs specific for each body with a price that is comparable to current apparel.

Second, is the current trend of millennial life. Studying your class closely, your generation wants to be flexible and ready for any new challenge while remaining stylish. (It is a quality that resonates with me, as you can appreciate my Die Hard movies). I hadn’t appreciated that by using 3D-printing seams disappear in clothes. As stated by you, this simple thing becomes a major improvement in durability.

Shifting gears to your questions and concerns.

Regarding innovations that can be made with machine learning: I would say that further improvement can come by monitoring the use of MoS clothes. With the Intelligent Heat Jacket you mentioned, MoS is introducing a power source in their apparel. Having this asset in, MoS could start monitoring variables such as time of use, sunlight exposure, humidity, friction, heat generation, and associate these variables with material, moment of tear, area of rip, among other factors. Having this data, may provide insights to MoS on which materials are better, what products are used the most (bring more benefit to their customer), and many more options. It would be an interesting moment to be in the apparel industry.