How Additive Manufacturing Can Improve Access to Adequate Housing

Additive manufacturing improves access to housing

A significant number of people worldwide lack access to housing and the number is growing; how do we begin to solve this global housing crisis? New Story is a nonprofit with the goal of pioneering solutions to address global homelessness. [1] Through partnerships New Story is exploring the applications of additive manufacturing to home construction. [2]

Currently 2% of the world’s population is estimated to be homeless, ~150 million people, while 20% lack access to adequate housing, 1.6 billion people. [3] While this issue has several causes, at its core is a lack of affordable construction. Incremental improvements in the conventional ways homes are built won’t solve the problem. Even in many developed nations the rate of homelessness has increased recently; Denmark, England, France, Ireland, Italy, the Netherlands and New Zealand are all developed nations where the rate of homelessness has been on the rise. [4] The world lacks the resources to meet the growing housing demand with the current processes.

Over the last four years, New Story has funded 2,000 conventionally constructed homes at a cost of ~$6,500 per home. [5] New Story, however, is exploring for a step-change. Additive manufacturing could represent that drastic reduction in time and cost and potentially increases the worldwide home construction capacity. Additive manufacturing is important to New Story’s process improvement because it potentially reduces the cost of these homes by ~40% to $4,000 per home and the building time to sub 24 hrs. [6] There are a couple issues New Story faces in the application of additive manufacturing to home construction; first, is additive manufacturing doesn’t address the entire home construction process. “A real functioning house would need to have its infrastructure and finishes added after printing, thereby putting real construction times in line with those of traditionally built houses.” [7] Secondly, the rate of deposition of material is an issue that must be addressed for this product to fully scale; the process must get faster for it to be truly competitive with the conventional process. [8]

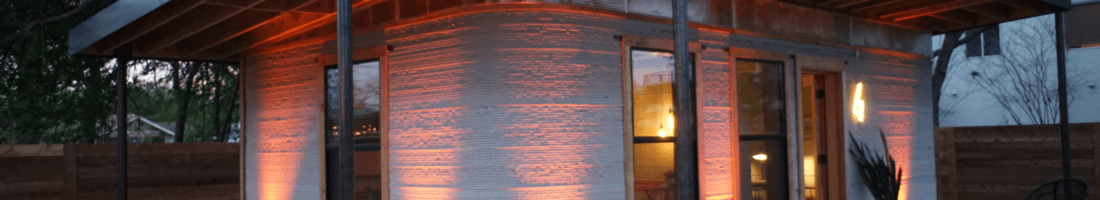

In the short term, New Story has partnered with Austin based startup Icon to address the speed issue. Currently, these two companies are focused on advancing the basic structural additive manufacturing process. Over the next year, the teams will utilize 3D printing to print a sustainable community in El Salvador. [9] 3D printing has been used to print individual homes, but this project represents the first largescale prototyping of additive manufacturing to create an entire community. For use on this project, Icon is currently developing the Vulcan II printer, which is estimated to reduce the construction time from 48 hours to sub 24 hours for one home. [10] Based on my research I couldn’t find significant steps being taken to attempt to address this finish out issue by New Story; however, many of their underlying values should create an environment conducive to innovation over the long-term. New Story is committed to open source innovation and a diverse ecosystem of partners. [11]

Understanding the magnitude of the issue is the first step in addressing it. I recommend New Story create and maintain a process flow diagram for the construction of a house to better understand and monitor how the bottleneck shifts with the evolution of this process. From this data collection New Story can understand the impact of future investments in both the speed and finish out. Furthermore, data can be shared with partners to focus their R&D efforts on the right steps in the process. In conjunction with better understanding the constraints of the process, I recommend New Story focus its attention over the next few years on additional partnerships with other construction technology companies. The partnership with Icon has proven very beneficial, but there are several other firms working to increase the rate of deposition of 3D printers. I recommend New Story seek additional partnerships, because they open the product development funnel further and could create additional breakthroughs or simply more incremental improvements that further increase capacity. Oak Ridge National Laboratory is one potential partner that is working on polymer and metallic deposition rates. [12] Ultimately, the more the process is improved, the more successful New Story can be at increasing access to adequate housing.

There are still several questions New Story should consider as it continues to apply additive manufacturing to the home construction industry. First, I would consider if New Story should begin to develop their own R&D team that is focused on improving the process specific to the homes they’re building versus partnering with for profit corporations? Second, are there other ways to address the resource requirements and variability of the finish out process without utilizing additive manufacturing?

(777)

End Notes:

[1] New Story Company, “Homepage,” https://newstorycharity.org/,” accessed November 2018

[2] New Story Company, “3D Printed Home,” https://newstorycharity.org/3d-home/, accessed November 2018

[3] Chamie, Joseph “As Cities Grow Worldwide, So Do the Numbers of Homeless,” Yale Global Online, https://yaleglobal.yale.edu/content/cities-grow-worldwide-so-do-numbers-homeless, accessed November 2018

[4] Ibid.

[5] New Story Company, “3D Printed Home,” https://newstorycharity.org/3d-home/, accessed November 2018

[6] Ibid.

[7] Kirkpatrick, Keith, “The Construction Industry in the 21st Century,” Communications of the ACM, Vol 61, No 3, March 2018

[8] Daniel Delgado Camacho, “Application of additive manufacturing in the construction industry – A forward-looking review,” Automation in Construction, Volume 89, May 2018, section 4

[9] New Story Company, “3D Printed Home,” https://newstorycharity.org/3d-home/, accessed November 2018

[10] Icon Build, “FAQ,” https://www.iconbuild.com/faq, accessed November 2018

[11] New Story Company, “Our Vision,” https://newstorycharity.org/vision/, accessed November 2018

[12] Daniel Delgado Camacho, “Application of additive manufacturing in the construction industry – A forward-looking review,” Automation in Construction, Volume 89, May 2018, section 4

Even though I believe that 3D printed homes for $4000 are a great step and advancement in addressing the world’s “homelessness” issue, I believe that its final impact will end up being limited for the time being. The reason for this is simple: Land property value. The real issue worldwide is the steep cost of land property, which is why so many people don’t have a place to live in. Moreover, another limitation I see is access to water, sewage, electricity and other utilities. This all costs money, adding up to the final cost of setting up a home, and access to basic utilities is extremely limited in developing countries.

So if you included all the costs that need to happen within the house, then how comparable is it with a normal property? What are some of the means in decreasing costs?

Any idea on the timeline of how far out they are from being able to do this?

Lastly, how logistically realistic is it to move this machine around?

I think one way that New Story could address the fit-out issue is combining 3D printing with modular building. A module that was one-part bathroom and the other part kitchen would contain all the water and sewer hookups required for a basic home. Modules can be pre-built in a factory, to include appliances and fixtures installed, and shipped to the construction site where the house can be built around them, preventing the need for a crane to lift them in place. By using a pre-built modules the entire house can still be completed within a day and be entirely fitted out.

Thanks for the interesting article! I would be interested in knowing who are the partners of New Story to fund the homes. $4000 could still be beyond a homeless person’s reach, specially given their lack of access to borrowing. Would these homes be designed for more rural or urban areas? I agree with some of the comments above, that we would have to factor in the cost of land, specially in urban areas.

Thanks for sharing. I love seeing the impact of 3D printing in this space and the social mission of the company. I actually came across another business called Katerra that follows a very similar business model and mission. They recently raised a big round of funding from Softbank (https://www.cnbc.com/2018/01/24/katerra-raises-865-million-from-softbank-vision-fund.html) to support ongoing growth in this extremely capital-intensive business. To really solve the issue of homelessness, we will need to do much more than building cheap homes for those who cannot afford them. There needs to be a comprehensive community-development effort that also creates employment opportunities, basic facilities for sustainable living (e.g., grocery stores rather than fast food restaurants) and more. In the absence of this ecosystem, the housing projects will likely fail to deliver on the well-intended mission. I would urge New Story to take this piece into consideration as well when looking for partners.

Interesting article! Thank you for sharing. Raises a very important question around the social impact of additive manufacturing in the housing context. Would like to understand how additive manufacturing can be sold as a time-saving even for large contractors. Particularly, since contractors and real-estate builders have significant capabilities in building houses in the shortest possible timeline and with least resources. What are the benefits that additive manufacturing can provide to such contractors?

Additionally, if additive manufacturing can also help in creating several models of houses through 3D printing, potentially it could be used to test out weather conditions. Particularly in areas with heavy wind, flood and rain conditions, actual 3D models could be used to simulate several different scenarios, test out weather-abilities of different construction materials, identify areas which need to be marked out where construction shouldn’t happen based on wind/flood conditions.

Thanks for this really interesting example attacking a big problem. I wonder whether this technology is only applicable to developing countries or also developed countries. In developed countries, I think much of the value from ‘the home’ is not just from the structure, but the idea of ‘the networked home.’ Homes are connected to many essential services – electricity, water, internet, etc. Can additive manufacturing be done in a way that allows structures to easily be connected to the network? I think this is an interesting question to think about for the strategy going forwards.

Hi SD – I love this article! Such a cool concept to 3D print houses, and I love the social enterprise spin. I watched some YouTube videos about them being built and it’s amazing. For your question, I think that partnering with for-profit corporations in order to improve the home building process isn’t necessarily a bad thing – there are companies that already have expertise in these realms that can assist, and I would imagine a lot of companies may be willing to donate consulting hours and the like for a tax break. There may be great opportunities here. Love this concept!

It’s fascinating to see how technology nowadays evolves to be able to create a house within 4000$ reach. I like that you bring up the social impact from the additive manufacturing in home construction. However, I do not completely agree that this will help solve the homeless issue as I believe that the homeless could not afford the houses anyway. The proper solutions to homeless issues would be to get them jobs, not to provide housing. The best way to teach people how to survive is to teach them how to fish not giving a fish to them.

In any case, I think the additive manufacturing in home construction can create huge environmental/social life impact. Imagine a typical construction process that not only took a long time to build but also create very noisy sound, dirty dust, lowering quality of life for people in general. If the 3D printing house can speed up the construction process and construct in the closed system environment, the quality of life for us will be much better off.

I love the idea of reducing cost and being able to provide more affordable housing. But as others have already pointed out, the mayor cost items in the construction of a home are relation to foundation setting, infrastructure connections such as sewage, clean water, and power, and depending on the region, insulation and finishing. Hence, if New Story were to pursue their own R&D team, it should not focus on pushing 3D printing technologies for constructing the building frame, but work on integrations and solutions that lower the cost of subsequent steps by integrating effectively with the printed frame.

I find it inspirational when emerging technologies are applied to some of the world’s most challenging and socially important problems. New Story is doing just this but utilizing additive manufacturing to tackle the global housing crisis. However, I wonder if this may be a case where solving one problem creates another. The construction sector and other jobs tangential to constructing homes (plumbing, electricians, etc.) employ many workers throughout the globe, and often provide employment opportunities to those who are sometimes less educated and privileged. I am curious to understand how additive manufacturing may be similar to automation and robotics in that it may have a social benefit and bring more efficiency to a certain industry but at the cost of human labor opportunities. In the near term, you note that the construction process still requires infrastructure and finishes to be done after printing, which also means that some tradition labor opportunities still exist. However, I wonder how the jobs required to conduct additive manufacturing compare to those of typical home construction from a skills and quantity standpoint.