From Toys to Your Butt, What’s IKEA going to Print Next?

In a rapid changing retail environment, how is the Swedish retail giant IKEA catching the wave of advanced manufacturing?

IKEA, the Swedish largest furniture retailer and manufacturer, known for its continuous product improvement and innovation is well positioned to take advantage of advancements in additive manufacturing technology.

Additive manufacturing(AM), or 3D printing, unlike the traditional subtractive method, promises flexibility in sophisticated designs that requires less material to produce. Since its inception in 1980s, AM has been slowly gaining traction owing to reducing cost, new processes, and greater research that drove the growth of the AM market. [1]

Prototyping has always been one of the key uses of 3D printing which accounted for 36% of application in 2014.[2] IKEA works with various designers to bring both product improvements and new products to its stores and shoppers. 3D printing allows fast prototyping and designers can have many more iterations of a design in a much shorter time frame. The flexibility in new product design would also enable IKEA’s designers to create more interesting and complex parts or finished products.

Another key advantage of 3D printing is that it allows reduction of material wastage. The conventional manufacturing process is subtractive where materials are gradually removed from the bulk to achieve desired feature. [3] This is a beneficial feature to large scale manufacturers like IKEA. In its most recent earning’s update, IKEA reported a drop in its underlying profit due to the rise of wood and metal prices. [4] This highlights the importance of managing material cost, therefore the promise of potential fast production with minimal waste by AM is certainly attractive to IKEA.

Over time as the manufacturing technologies develops further, the initial constrains of 3D printing has been greatly reduced. IKEA’s own journey with 3D printing illustrated how the application spectrum of 3D printing has been gradually expanding.

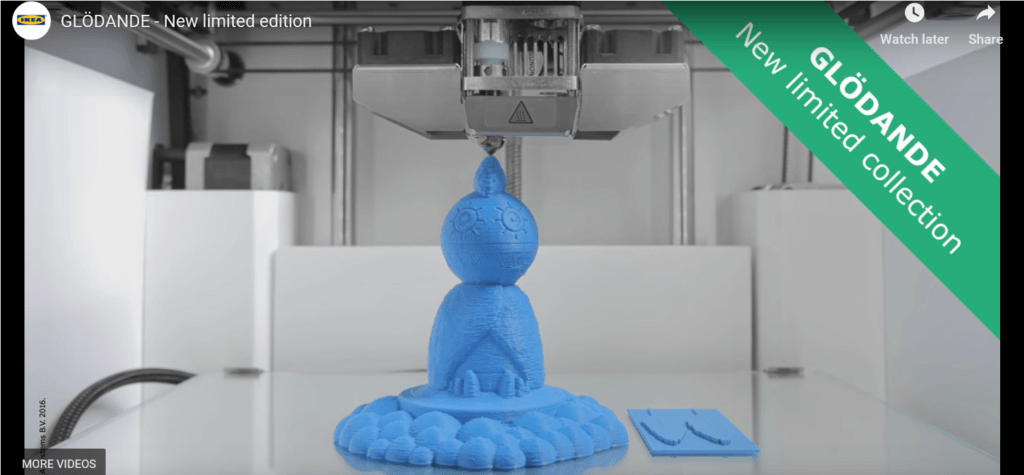

IKEA initially dabbled with 3D printing as an extension to its creative design and conceptual offerings. In 2016, IKEA collaborated with Anterwerp-based fashion designer, Walter Van Beirendonck to produce GLÖDANDE collection which was inspired by Van Beirendonck’s Children’s book. Wondermooi, the characters from the book were made available for 3D printing at Swedish stores [5]. Later in 2016, IKEA also released a 3D knitted chair using 3D printing knitting technology as a part of its experimental design for its 2017 catalog [6].

In 2017, collaborating with Ireland-based Wazp – one of the world’s biggest manufacturers of 3D printed objects by volume [7], IKEA was the first larger furniture manufacturer to initiated 3D printing mass production project. The product was a metal-mesh, stylistic, deconstructed human hand, a decorative piece in IKEA’s OMEDELBAR collection that can be used both as a decorative jewelry holder or unique wall art. This complex design of this product would have been impossible using the traditional injection technology.

Finally IKEA saw a bigger commercial opportunity utilizing photometric and 3D-scanning in combination with 3D-printing in the 2 Billion gamers industry.[8] Jun 2018, IKEA announced collaboration with UNYQ, a 3D printing medical wearables company, and Area Academy, an educational e-sport company to make specialized and highly personalized gaming chair. The ordinary looking hydraulic stool is expected to be fitted with two-panel mesh platform that’s been 3D-printed to achieve a perfect fit to the individual game’s gluts. These chairs are expected to become available starting in 2020. [9]

Looking ahead in the near term, as IKEA continues toying with 3D printing, it would be a logical next step for IKEA to find a way to introduce the ergonomic technologies used in the high-end gaming chair to other IKEA furniture, hopefully in a more economical manner as the economics always matter the most to the mass market.

In the longer term, IKEA should look beyond product development using 3D printing and consider the impact this technology has on its overall business. Additive manufacturing has the potential to transform the way products are manufactured and brought to the market. IKEA currently operates a complex global supply chain system managing raw materials that are used to build product, extend to the distribution and management of storage and inventory[10]. As 3D printing enables the possibility of manufacturing at point of use, IKEA could potentially benefit from reduced inventory and storage space at its shops. This could even further trigger re-thinking of the design of the existing IKEA stores.

Two open-ended questions for debate are:

- Should IKEA consider building in-housing 3D printing capability instead of outsourcing to existing 3D printing companies?

- Can IKEA charge consumer more for 3D printed products with the argument that there are additional sustainability benefits in reducing material waste using a more expensive technology?

(Word Count: 742)

Reference

[1] Kerns. What’s next for 3D printing? The disruptive technology continues to grow thanks to lower costs and greater accessibility. Machine Design 90, no. 1 (January 2018): 36–42.

[2] M.J. Cotteleer. 3D opportunity: Additive manufacturing paths to performance, innovation, and growth. 2014 Additive Manufacturing Symposium, Deloitte Services, LLP, October 1 2014

[3] W.J. Lim, K.Q. Le, Q. Lu, and C.H. Wong. An overview of 3-d printing in manufacturing, aerospace, and automotive industries. IEEE Potentials35, no. 4 (2016): 18–22.

[4] Reuters Video. Ikea’s profit hit and it’s not alone this Q3..[online] Reuters. 12 November 2018. Available at: https://www.reuters.com/video/2018/11/12/ikeas-profit-hit-and-its-not-alone-this?videoId=482417202&feedType=VideoRSS&feedName=Business&videoChannel=5 (Accessed: 12 November 2018)

[5] IKEA official website. https://www.ikea.com/ms/en_US/this-is-ikea/ikea-highlights/3D-printing/index.html (Accessed: 12 November 2018)

[6] C. Scott. 3D Knitted Chair in IKEA’s PS 2017 Collection Is Both Eye-Catching and Comfortable.[online] 3Dprint.com 19 December 2016. Available at: https://3dprint.com/159146/3d-knitted-chair-ikea-ps-2017/ (Accessed: 12 November 2018)

[7] S. Saunders. 3D Printing in Mass Production: IKEA Announces the Upcoming Release of Its Unique 3D Printed Collection..[online] 3Dprint.com 11 July 2017. Available at: https://3dprint.com/180726/ikea-3d-printed-collection/ (Accessed: 12 November 2018)

[8]IKEA official website. https://newsroom.inter.ikea.com/about-us/all/ikea-in-collaboration-with-unyq-and-area-academy-to-improve-gaming-and-life-around-it/s/9b07005d-60a1-44b2-be7d-662824481380 (Accessed: 12 November 2018)

[9] M. Wilson. IKEA wants to 3D scan your butt. [online] Fast Company. 10 September 2018. Available at: https://www.fastcompany.com/90233283/ikea-wants-to-3d-scan-your-butt (Accessed: 12 November 2018)

[10] Brown. Chain reaction: Why additive manufacturing is about to transform the supply chain. Mechanical Engineering 140, no. 10 (October 2018): 30–35.

Really cool article! Classic of Ikea to innovate in product design.

On your question regarding whether or not the company might be able to charge a premium for 3D printed products simply for the environmental benefit, I’m inclined to think the answer is ‘not really’. That’s not to say there isn’t a faction of sustainability-focused consumers for whom that would be appealing, but I think to really attract the masses, you have to emphasizes more immediate benefits to the consumer. The reality is, given their cost positioning, Ikea serves a price sensitive customer base. Therefore, if the end consumer advantages of 3D printing were better highlighted (e.g. improved aesthetics, durability, personalization) it could perhaps provide a more compelling value proposition.

It is interesting that IKEA is experimenting with 3D printing while it is still in a fairly non-commercial stage as a technology. On one hand, IKEA is known for being innovative, but on the other hand, I think of IKEA as a company whose success has been driven by their ability to mass produce in a very affordable way, so introducing a technology focuses on customization is a step outside of their wheelhouse. Because 3D printing is still a fairly young technology, and has high costs that go along with that, I think IKEA should continue to outsource this work to existing 3D printing companies. It seems that they are trying out different approaches to 3D printing (customization, intricate designs, prototyping), and by outsourcing they can continue to experiment with ways to implement without committing to building capabilities catered to one approach. Regarding whether they should charge more – to me it depends on whether they want to make this a core part of their product line and sell high volumes, or use 3D printing as a way to expand their price range upwards with a higher-end line of customized, highly designed items. However they intend to sell this in the long-term, they should focus on building credibility at that price.

I enjoyed reading your article and insights about applying additive manufacturing to furniture. I agree that the application of 3D printing has potential to disrupt the existing supply chain and create a new ecosystem of distribution. The critical advantage the technology has over traditional manufacturing is the ability of mass customization. Like the example of the gaming chair, IKEA could attract more customers by making customized products, such as sofas and tables, which best fit their body and the interior. I believe IKEA could price its products higher by providing more value not only from sustainability benefits, but also from customization service that only 3D printers can achieve.

I believe IKEA’s use of 3D printing should be limited to home decorations, for which they can charge a premium and won’t have to disrupt their in-store operations to accommodate. The value prop IKEA offers for furniture is affordability, but for decorations it is style; as such, I think customers will be more willing to pay a premium on 3D-printed decorations rather than a couch. Additionally, whole 3D-printed items would throw a wrench into the furniture pick-up section of IKEA, which relies on the stacking of tightly-packed cardboard boxes (vs. bins for home decorations).

Given the assumption that IKEA will not expand fully into 3D-printed furniture, I do not think it is necessary for them to bring the capability in-house. Cheaply producing 3D-printed items at scale is challenging and they should leverage the experience of their partners in that matter.

Great title and fascinating article!

While I agree about the potential for in-store 3D printing, particularly if it could significantly reduce supply chain costs, I’m not sure they need to build the capabilities in house vs partnering with those who are developing 3D printers. IKEA’s core competency is around designing furniture, and I’d worry investing in the development of 3D printers might not align with their skill-set particularly as 3D printing is still relatively early in its development curve.

I think IKEA could charge more for 3D printed products, but not necessarily for the sustainability reasons. If I were them, I would charge more for the customization aspects (like a chair designed specifically for me to sit on vs anyone else) rather than for social reasons which may be difficult to quantify.

Thanks for the interesting sharing!

I think to IKEA, the value of 3D printing is allowing them to have additional product lines — more complicated interior decoration and high-end customized furniture. I think these two directions of using 3D printing are actually quite different from their current brand image — affordable, designed but mass-produced furniture. I believe this will open up new business opportunities for IKEA, though I’m also more conservative on how much profit it can bring as the market should be relatively small. I think the overall question for me is that does IKEA want to use 3D printing to just add more colors and products to their main brand, or they believe in the potential and would like to push forward on creating specific product line using 3D printing? No matter which way they choose, it’s for sure that IKEA will be more diversified and have more customized touch on products.