Artificial Intelligence Taking Off for Airbus

In an increasingly competitive and innovative landscape, can Airbus use machine learning to improve efficiency while not sacrificing on safety?

From the Wright Brothers’ glider to the modern 4-engine airliner, the aviation industry has always been at the forefront of technological innovation. Now, newer technologies such as artificial intelligence and machine learning continue to grow exponentially in this space. Airbus, one of the major aerospace players, recognizes the potential influence of machine learning in its operations and product development, and it has both short-term and longer-term plans to implement it effectively.

Why is Machine Learning Important for Airbus?

What sets the aviation industry apart is its complex and costly manufacturing process, stringent regulations, and high levels of competition and innovation.

Aircraft manufacturing requires both machine and human processes that work in tandem. With hundreds of thousands of different components to a plane, manufacturing often takes place at remote manufacturing plants before all the parts are transported to the final assembly line[1]. While the manufacturing process of a plane ranges from 3-6 months, new product design can take upwards of 8 years[2].

In addition to a complex manufacturing process, aircrafts are also subject to intense degree of scrutiny and regulation, as most countries have national aviation authorities[3]. The necessity for high safety requirements means that the margin for error is especially low for Airbus.

Finally, Airbus must also contend with competition from its main competitor, Boeing. The two companies have gone toe-to-toe for decades and often release new aircrafts within the same year[4]. At the recent 2017 Paris Air Show, Boeing won more orders than Airbus for the first time since 2012, putting increased pressure in Airbus to innovate quickly[5].

Within this highly competitive and regulated environment, machine learning is one of the few ways that Airbus can improve product design and efficiency quickly while keeping the margin of error low.

Airbus and their Use of AI and Machine Learning

In April of 2017, Airbus CEO Tom Enders said in an interview, “I do genuinely believe that we are at a point where those technological changes and breakthroughs in electric propulsion, autonomous flight, artificial intelligence, machine learning, new materials, all come together, plus the data usage, and will be nothing less than a third revolution in aerospace.” [6]

With this “third revolution” in mind, Airbus has explored the possibilities of machine learning primarily within two areas: Manufacturing improvements and increased data insights for their airline customers.

In manufacturing an aircraft, numerous production difficulties can occur. In the short term, Airbus has utilized machine learning on the production floor to mitigate this. In the development of their newest A350 model, Airbus wanted to move faster without compromising on quality[7]. To meet the goal of faster production, Airbus began a data collection process that documented all the issues and actions that took place on the shop floor. The system generated recommendations to suggest the best course of action, should a problem arise. In the longer term, Airbus is hoping to more fully automate the manufacturing process with more machines and less people, further enabling higher production[8].

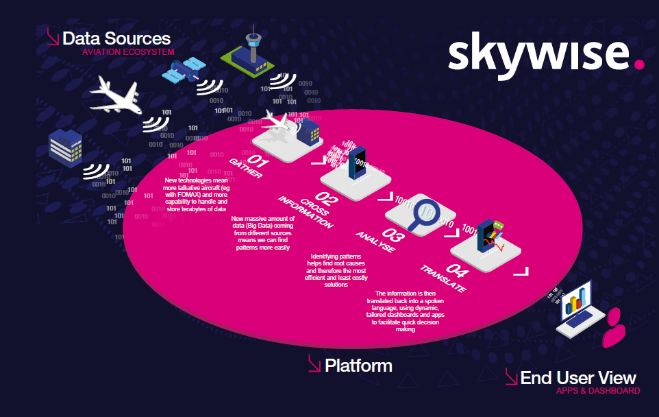

Airbus is also using their huge amounts of data to help provide insights and predictive analytics to airlines. In 2017, Airbus launched Skywise, an open data platform that assists airlines with flight operations analysis, predictive maintenance, and troubleshooting on an ongoing basis[9]. Airbus uses onboard sensor data to provide this information (Airbus’ A350 model has 250,000 sensors aboard and can measure 900,000 system parameters)[10]. They will continue to sign more airlines to this platform, and in the longer term, make this solution available for helicopters, military aircraft, and other products[11].

Next Steps for Airbus

One area of AI less explored by Airbus is the notion of “self-flying planes.” While a large part of aircraft operations is automated, the pilot remains an indispensable part of the journey. However, it is most likely safer to be in a plane not subject to human error. I recommend that Airbus explore this possibility and invest in making this a reality. Indeed, the use cases for machine learning are infinite, not only in commercial flight, but in the defense and military sectors as well. It is in the company’s best interest to invest in machine learning startups and talent that can help dream up solutions for problems Airbus has not even begun to identify.

Of course, questions remain about how large of a role AI and machine learning can have in aviation. Do you foresee regulatory risk in what Airbus would be able to implement going forward? Are there additional safety concerns if this industry continues to rely more on machines?

(Word Count: 749)

[1] Airbus, “Enhancing Production,” https://www.airbus.com/aircraft/how-is-an-aircraft-built/production.html, accessed November 2018.

[2] Leggett, Theo, “A350: The aircraft that Airbus did not want to build,” BBC News, June 14, 2002, https://www.bbc.com/news/business-22803218, accessed November 2018.

[3] Federal Aviation Administration, “FAA Regulations,” https://www.faa.gov/regulations_policies/faa_regulations/, accessed November 2018.

[4] Zhang, Benjamin, “How Airbus became Boeing’s Greatest Rival,” Business Insider, September 8, 2018, https://www.businessinsider.com/airbus-history-boeing-rivalry-2018-4#in-july-airbus-took-full-control-of-the-c-series-program-from-bombardier-and-rebranded-the-innovative-carbon-composite-jet-the-a220-36, accessed November 2018.

[5] Ostrower, Jon, “Boeing vs. Airbus: A new winner emerges at the Paris Air Show,” CNN Money, June 22 2017, https://money.cnn.com/2017/06/22/news/paris-air-show-boeing-airbus/index.html, accessed November 2018

[6] AIAA, “Airbus CEO Enders: Aerospace Industry On Brink Of “Third Revolution,” https://aviation.aiaa.org/Notebook.aspx?id=15032387008, accessed November 2018

[7] Ransbotham, Sam, “Accelerate Access to Data and Analytics With AI,” MIT Sloan Management Review, August 22, 2017, https://sloanreview.mit.edu/article/accelerate-access-to-data-and-analytics-with-ai/, accessed November 2018.

[8] Hepher, Tim, “Airbus chief says automation to revamp jet manufacturing, help meet demand,” Reuters, June 3 2018, https://www.reuters.com/article/us-airlines-iata-airbus-interview/airbus-chief-says-automation-to-revamp-jet-manufacturing-help-meet-demand-idUSKCN1IZ0AZ, accessed November 2018.

[9] Airbus, 2017 Annual Report, p. 9, https://www.airbus.com/investors/financial-results-and-annual-reports.html#annualreports, accessed November 2018.

[10] ESMT Knowledge, “Tom Enders: Digitalization fuels modern aerospace and aeronautics,” https://knowledge.esmt.org/article/tom-enders-digitalization-fuels-modern-aerospace-and-aeronautics, accessed November 2018.

[11] Airbus, 2017 Annual Report, p. 9, https://www.airbus.com/investors/financial-results-and-annual-reports.html#annualreports, accessed November 2018.

Interesting article! I agree that big-data platforms are going to revolutionize the operation of complex operations such as airlines, and I hope that translates to the passenger in the form of a better experience, improvements on on-time performance and decreasing prices. I do agree that the next should be self-piloted aircraft, but two issues arise immediately: regulation bodies that are extremely bureaucratic and pilot unions that have lots of power in the industry, probably blocking those type initiatives for years if not decades.

Very interesting take on the aerospace industry. Machine learning and artificial inteligence seem to make a lot of sense when it comes to both prodcution and safety. However, I do think that there will be additional safety concerns if this industry continues to rely more on machines. While it is true that human error plays a large part in accidents, I doubt that we will see self-flying planes in the future. Having a human there, even if not flying the plane actively, can be critical in emergency situations that require situational awareness and cost-benefit analysis based on human life.

Interesting article. I like how well-structured your argument is for how machine learning can be used to improve both the design and manufacturing process of Airbus planes. The biggest concern I see about applying Airbus’s machine learning capabilities to “self-driving planes” is the lack of overlap there is into the two different types of use cases. In the current case, machine learning is being applied to tackle incremental changes to manufacturing and making plane production more efficient. “Self-driving planes”, on the other hand, require a more transformative and breakthrough technological advancement. This new application would directly impact the amount of talent and resources Airbus would need to make self-driving planes come true.