DHL Vision Picking – Blurring Digitization and Manual Labor Through Augmented Reality

DHL's Vision Picking glasses use AR to enhance warehouse pickers efficiency and effectiveness as it moves toward Industry 4.0

Vision Picking – Pilot program

In January 2015, DHL, Ricoh, and Ubimax partnered to conduct a pilot program to improve the operational efficiency of manual picking in warehouses by using augmented reality. “Pickers are equipped with advanced smart glasses which visually display where each picked item needs to be placed on the trolley. Vision Picking enables hands free order picking at a faster pace, along with reduced error rates” [1]. “The displays showed the respective task information during the picking process, including aisle, product location and quantity… and reduced the time it took the manual picker to correctly gather the items in the carts by 25%” [2].

[3]

[3]

“The vast majority of warehouses in the developed world still use the pick-by-paper approach. But any paper-based approach is slow and error prone. Furthermore, picking work is often undertaken by temporary workers who usually require cost-intensive training to ensure they pick efficiently and without making errors” [4] The pick-by-paper approach described is an approach where the picker has a paper (or tablet) showing the list of items that need to be picked from the shelves and put into the cart. The picker then marks off the item as they are completed. Some improvements to that system have been employed where it digitizes the list and uses a handheld scanner.

The efficiency noted earlier is comparing a handheld barcode scanner and a clipboard with a printed paper that can quickly be checked off. Part of the benefit comes from the hands-free aspect of the Vision Picking glasses so the picker doesn’t have to put down the scanner to pick up the item and move it to the cart. Another part of the benefit is that the picker is shown visually in the glasses what the best way to get to the location of the next items in the large warehouse. As the items are scanned and put into the cart, the Vision Picking glasses also indicate which spot of the cart to put it in and how many items should go there, which reduces errors. If you were an inexperienced picker trying to make sure you had the right items using the old picking system, you would have to make sure you were looking at the right line. With the Vision Picking glasses you would only have the right information displayed so you wouldn’t have the possibility of making an error by reading the wrong line.

Putting Vision Picking into Perspective

While it certainly is exciting for warehouse workers to use new technology to improve efficiency and reduce errors, this is only part of the journey that DHL is working toward a greater cyber infrastructure. DHL’s Supply Chain CEO John Gilbert said, “We are excited to further test and develop vision picking as a solution that can be readily available to our customers. More importantly, this technology is not just one step towards digitalizing manual processes on the shop floor, it also takes us one step closer towards Industry 4.0. Testing technologies like augmented reality, robotics and Internet of Things will continue to be a big part of our DNA” [1].

Industry 4.0

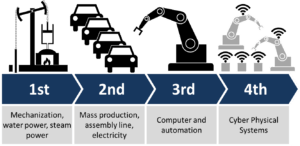

What is industry 4.0? Industry 4.0 is defined “as the next phase in the digitization of the manufacturing sector… [dubbed ‘4.o’ because it is] the fourth major upheaval in modern manufacturing” [6].

“Industry 4.0 introduces what has been called the “smart factory,” in which cyber-physical systems monitor the physical processes of the factory and make decentralized decisions [using machine learning algorithms]. The physical systems become Internet of Things, communicating and cooperating both with each other and with humans in real time via the wireless web” [7]. The competitive advantage of a smart factory over a Industry 3.0 factory could be significant, but there are also a couple of concerns that need to be addressed.

Challenges to Industry 4.0 Implementation

Challenges to implementing the Industry 4.0 model include:

1) data security of integrating new systems,

2) the high degree of reliabiltiy and stability of the cyber-physical communication,

3) quality control without human oversight, and

4) loss of jobs for workers being displaced by automation [see 7].

Future Reality?

While DHL’s use augmented reality with Vision Picking is impacting reality, how quickly will Industry 4.0 become a reality? Would your answer be different if you led the transformation? (718 words)

[1] http://www.dhl.com/en/press/releases/releases_2016/all/logistics/dhl_rolls_out_global_augmented_reality_program.html

[2] http://www.supplychain247.com/article/vision_picking_in_the_warehouse_augmented_reality_in_logistics

[3] image: http://www.dhl.com/content/dam/Local_Images/g0/press/releases/images/group/pr_g0_083116_full.jpg

[4] http://www.dhl.com/en/press/releases/releases_2016/all/logistics/dhl_rolls_out_global_augmented_reality_program.html

[5] image: http://www.allaboutlean.com/industry-4-0/

[6] http://www.mckinsey.com/business-functions/operations/our-insights/manufacturings-next-act

[7] http://www.forbes.com/sites/bernardmarr/2016/06/20/what-everyone-must-know-about-industry-4-0/#1ceebe044e3b

As technology is introduced into our manufacturing processes, there is a fine line in the design of this technology as to when there is too much information presented to the person performing the task. The vision glasses seem to have gotten this aspect of the design right, however there are times when engineer’s don’t get it right, and rather than taking a step forward with technology, its two steps backward. In the implementation of the glasses there were two forces at hand, the technology itself and then the acceptance of that technology by the pickers. If either was unsuccessful, then the project failed. As information becomes digital in our manufacturing sector, it will be interesting to see how people integrate this into their daily operations to minimize errors and improve efficiency.

Very interesting read! When I first read this article, I thought of it as an interim solution for the global logistics industries, because eventually labor will be entirely replaced by automated machines. In fact, Amazon and a few leading Chinese warehousing companies have been using robotic arms to automate the “fetching” process. This also reminds me a similar technological trend in the automotive industry, where aided-driving technology is an interim solution, leading to eventually autonomous driving. The question is, how long would it take for the next industrialization (i.e. Industrialization 5.0) take place, and will its technology be built upon the 4.0 or will it be even more drastically groundbreaking?