Crowdsourcing at Adidas – Be The Designer

Crowdsourcing designs, machine learning, and efficient manufacturing processes have all been a part of Adidas' strategy for the future. With the help of open innovation the company has managed to turn its fortunes around and will be aiming to narrow the gap with Nike.

Crowdsourcing at Adidas:

Crowdsourcing has become an incredibly important part of Adidas’ strategy. In April of 2018, the company launched its second Speedfactory [1], a new concept which, combined with machine learning, enabled sneaker enthusiasts as well as amateur athletes to become an integral part of the production development process. Adidas fans were given the freedom to design their own shoes with very few limitations around materials. Based on these designs and with the help of big data, Adidas could shorten the length of the production funnel dramatically. What would normally be an 18-month long prototyping, designing, and production process could be shortened to just 24h [2].

This radical approach to design and the shift towards open innovation highlight the competitive nature of the industry. For Adidas, a company long in the shadow of its main competitor Nike, innovation has always been critical to success. Beyond the established players, new market entrants such as Lululemon and Vuori pose further challenges for Adidas [3]. Customer reviews, feedback, and most importantly notoriously difficult to predict preferences determine the future success of the company. To stay ahead of the innovation curve, Adidas has placed a bet on the power of open innovation. Crowdsourcing is the key to future product development; being able to spot trends before they even fully materialize is a huge advantage in the fast-movingworld of sneaker design. Even more than that, the hope is that enabling consumers to have a say in the brand’s designs will build strong brand loyalty, which will enable long-term relationships between consumer and company.

Addressing the issue:

In the short term, Adidas has made big bets on open innovation through its two Speedfactories in Germany and Atlanta. These represent a significant financial outlay for the company but are indicative of the importance management places on crowdsourcing. In the next two years, Adidas’ leadership will be focusing on the return of these investments and the company’s ability to analyse the large amounts of data coming streaming in.

While a step in the right direction, these trials are only the first of many bets that Adidas is likely to have to make. If successful, the crowdsourcing model could become the future of sneaker design. However, competitors are already making similar moves into the digital space. For example, Nike just launched a its experimental store – Nike By Melrose – and is aiming to use data from its Nike Plus members in order to provide localized inventory management and personalized customer service [4]. With that in mind, in the medium term, it will be critical for Adidas to continue to innovate in this space and give its members the ultimate sneaker experience. Further integration of big data with design and raw material stocking will be key. Through its open design platform, Adidas has access to huge amounts of data that can be used to accelerate its ability to spot trends. Integration of 3D printing as seen in certain Adidas lines such AdidasMade4 (AM4) could help further reduce costs, especially with the rapid improvement in the technology [5].

Further steps:

To address the open innovation issue head-on in the short term, Adidas should focus on advertising its rapid design capabilities. The two Speedfactories are an example of the successful integration of big data, crowdsourcing, and efficient manufacturing processes. However, Adidas has so far failed to reach consumers outside the sneakerhead circles. Organizing design contests and featuring winners and their sneakers on social media would be a fantastic way to reach wider audiences.

In the medium term, Adidas should invest in further Speedfactories in order to shorten shipping time and, most importantly, increase capacity. If, in fact, management believes in the scalability of customized orders and designs, it is imperative that the company continues to develop its manufacturing capabilities. With high automation levels at its Atalanta and Germany plants, Adidas has managed to decrease costs. Further savings in this area could decrease any potential cost increases due to one-off production jobs.

Two questions:

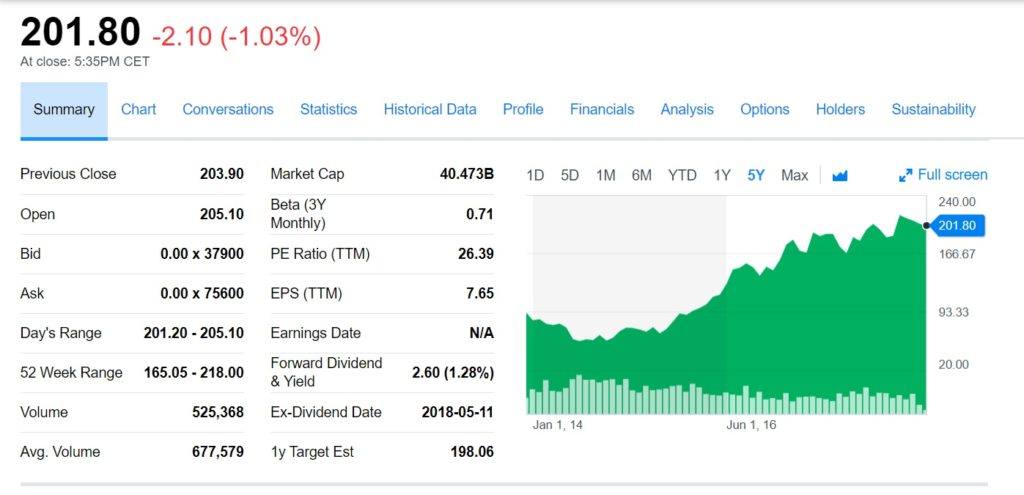

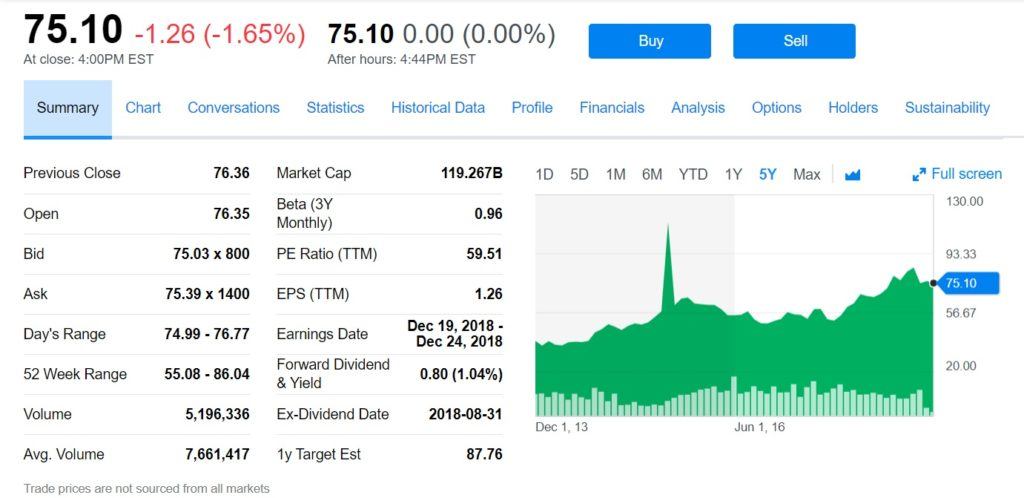

Question 1) I would be curious to learn what my classmates think of Adidas’ chances of surpassing Nike (See exhibits 1a & 1b). Would open innovation be enough to close the gap significantly and if not, what are some further strategies Adidas could employ stay ahead of the competition?

Question 2) One issue with crowdsourcing is the scalability of the Speedfactory concept. How does one go from creating single customized designs to selling large quantities while keeping costs down? Is this just a gimmick Adidas is using to attract attention, or does the future lie in customized one-off orders?

Word count: 763

Exhibits:

Exhibit 1a – Adidas Performance last 5 years (Yahoo Finance)

Exhibit 1b – Nike Performance last 5 years (Yahoo Finance)

Sources:

[1] Kim Windyka, “Machine Learning Lets Adidas Customers Contribute To Product Design”, www.psfk.com, 13 June 2018, https://www.psfk.com/2018/06/machine-learning-adidas-product-design.html. Accessed November 11th, 2018.

[2] Susan Galer, “In Just 24 Hours, Machine Learning Delivers Your Custom-Designed Adidas Sneakers”, www.forbes.com, 14 June 2018, https://www.forbes.com/sites/sap/2018/06/14/in-just-24-hours-machine-learning-delivers-your-custom-designed-adidas-sneakers/#30ed60ca1117. Accessed November 11th, 2018.

[3] Darren Heitner, “This Multimillion-Dollar Men’s Athleisure Startup Is Coming After Lululemon’s Market Share”, wwww.forbes.com, 27 July 2018, https://www.forbes.com/sites/darrenheitner/2018/07/27/this-multi-million-dollar-mens-athleisure-startup-is-coming-after-lululemons-market-share/. Accessed November 11th, 2018.

[4] “Nike’s New Store Was Located And Stocked By You, Los Angeles”, www.nike.com, 12 July 2018, https://news.nike.com/news/nike-by-melrose-store-los-angeles. Accessed November 11th, 2018.

[5] Marc Bain, “Adidas can now make specialized shoes for runners in different cities, thanks to robots”, www.qz.com, 4 October 2017, https://qz.com/1081511/adidas-can-now-make-specialized-shoes-for-runners-in-different-cities-thanks-to-robots/. Accessed November 11th, 2018.

To answer your second question, I think the answer might lie in one of the other 2 innovations / themes of this TOM challenge! 3-D printing products should help decrease the complexity of producing individual, one-off, more intricate products. Adidas would then have to adopt several of these next generation technologies to make this program a success. Given its a large established player, what is the likelihood it will be able to do this fast enough before a smaller, scrappier company does?

Interesting article, and I like the comment from ABCDEF as well! I agree that it’s uncertain whether this can move the needle for Adidas. Even if it is not a huge driver of creativity and eventually sales, I do agree they should lean into it from a brand marketing perspective. It’s cool that they are trying this, and I bet it would help bring more people into the fold to publicize things more.

I haven’t thought about Adidas since middle school. In fact, I had to Google its slogan to remind myself what it was. Their slogan, “impossible is nothing” [1], didn’t ring a bell. You asked if we think Adidas could potentially surpass Nike and my lack of brand awareness makes me think not. While I do appreciate their efforts to innovate via the Speedfactories, they need to double down on advertising the crowdsourcing component. Given the diffusion of social media today, my advice to them would be to kick off an online design competition with the winner’s design transitioning to mass production. Another idea is to host a bootcamp for teens and have designing be part of the camp activities aside from sports (similar to what Nike did pre-2010 World Cup). Crowdsourcing serves as a product development expeditor but can also serve as a marketing mechanism.

Citation:

[1] https://www.adidas-group.com/en/group/history/, accessed November 2018.

I think the second question you posed is an interesting one. While the Speedfactory concept may enable Adidas to better serve regional markets, scaling the concept could certainly be a challenge. However, I think that where Adidas could truly benefit is not in scaling up the number/quality of Speedfactories, but in opening up a necessary number of Speedfactories in key regions for the sole purpose of collecting data on emerging preferences in footwear. That data would be invaluable, in that it could inform how Adidas shapes their prominent lines moving forward.

Super fascinating to see how Adidas is innovating across many different areas relevant to TOM! In response to your question 1, for Adidas, I think them surpassing or rising to the level of Nike is not a question of innovation but rather a question of marketing. In my opinion, Nike has done a far better job in marketing, advertising, and appealing to its customers and that is why they outperform. When I compare these companies on a pure product basis, I don’t think that their products are that differentiated.

For your second question, I would be curious to see how these items are priced or have Adidas do a data sampling how these products should be priced. One thought would be to do collaborations with their ambassadors (like Karlie Kloss) to advertise this product offering and try to attract consumers to the brand.