Cotton in footwear and apparel manufacturing

Cotton, the most widely used natural fibre, is highly susceptible to climate change. What is the response of footwear and apparel manufacturers, who rely heavily on fibres in their production, to the supply chain disruptions?

Cotton, the most widely used natural fibre, is highly susceptible to climate change. Each year, some 22 million tons of raw cotton are produced but according to even the slowest climate warming models, the US production could go down by 30 to 46 percent by 2100 [1]. For footwear and apparel manufacturers such as Nike, who rely heavily on fibres in their production, climate change could cause major supply chain disruptions in the future.

Cotton production in the face of climate change

The key challenges associated with climate change are rising temperatures, droughts, increase in extreme weather patterns and higher CO2 levels.

Rising temperature has a dual effect on cotton production. Higher temperatures can increase cotton yields in cooler areas by extending the growing season, but many areas will become too hot to grow cotton. Although cotton can survive in higher temperatures, sufficient water levels become crucial as plants need water to maintain their temperature within an optimal range. As a result, an estimated 73 percent of all cotton worldwide is currently grown with partial or full irrigation. With increasing freshwater demand and competition for water availability in many countries, droughts become an important factor limiting cotton production [1]. According to a report by the House Committee on Natural Resources, the drought of 2011 in Texas resulted in an estimated financial loss of roughly $2.2 billion [2]. However, cotton is also susceptible to damage from floods and unexpected heavy rain because drenched roots cannot provide sufficient amounts of nutrients and oxygen from the soil.

Furthermore, as temperature rises, insects and diseases are likely to pose additional threats. Firstly, plants have a harder time adapting to temperature changes than animals. Secondly, higher temperatures could so lead to prolonged periods during which insects are active and speed up reproduction rates, both factors leading to further deceasing cotton production. [1]

Nike’s response to climate change

In response to the broad range of climate change issues, Nike has done a lot of work to understand its supply chain to eliminate waste and reduce its carbon footprint, which has led to its decreased dependency on cotton.

Firstly, Nike has done a lot of work to make its manufacturing technologies and product design more efficient. Nike’s Flyknit technology leads to waste reduction of 60% in comparison to traditional cut-and-sew methods [3]. According the Nike, the technology has eliminated nearly 3.5 million pounds of waste since 2012 [4].

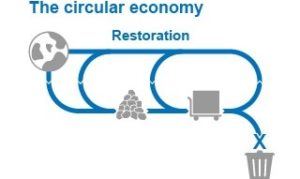

Secondly, in an effort to move from linear to circular economy, where materials are reused or upgraded for other productive applications through as many cycles as possible [5], Nike improved its waste management and recycling. Nike a introduced the Nike grind – a palette of premium recycled materials – used in 71% of Nike footwear and apparel products. Moreover, Nike uses polyester for some of its premium products recycled from billions of plastic bottles. [4]

According to Nike, “in FY15 alone, 54 million pounds of factory scrap was transformed into premium materials used in Nike performance footwear and apparel. In footwear manufacturing, we diverted 92% of total waste from landfill and incineration without energy recovery.” [4]

Going forward

Although Nike is a leading example of a for-profit company acknowledging its impact on the environment and making huge leaps towards zero carbon footprint, there are ways to go further.

In the medium run, Nike should double down on recycling waste into fibres used for footwear and apparel production. Not just their own waste, but also waste from agricultural production. New emerging technologies can now be used for upcycling, i.e. turning crop residue into new fibre.

One of the alternative materials used by Nike is semi-synthetic fibre called rayon. Today, rayon is made primarily of chemically treated wood pulp. As such, although seemingly more sustainable, rayon production still puts a lot of pressure on the environment [6] and thus is not in line with Nike zero carbon footprint and is more threatened by climate change.

In today’s ever-changing environment, Nike needs to continuously look for new sources of reducing its footprint and dependency on fresh raw materials. Tyton Bio, a U.S. based company, can serve as an example of a new partnership that Nike could pursue. Tyton Bio uses a hydrothermal process to turn old cotton or waste such as sugar can bagasse or wheat straw into rayon, with a better than 90% reduction in chemistry [7].

As climate change continues to put pressure on the environment and the society, a few questions arise: Is it enough for companies to react to climate change only to the extent to which it directly impacts their value chain? Should it be a company responsibility to reduce its carbon footprint? Can it be made mandatory in the near future for most or all businesses?

Word count: 789

[1] International Trade Centre(ITC), Cotton And Climate Change: Impacts And Options To Mitigate And Adapt, Geneva: ITC, 2011. xii, 32 p. (Technical paper) Doc. No. MAR-11-200.E

[2] House Committee On Natural Resources, Texas House Of Representatives, A Report To The House Of Representatives 83rd Texas Legislature, January 2013 http://www.weat.org/govt/2013HouseNaturalResources-Interim-Report.pdf

[3] Nike, “Nike news”, https://news.nike.com/news/sustainable-innovation, accessed November 2017

[4] Nike, “About Nike – Sustainable Innovation: Minimizing Environmental Footprint”, https://about.nike.com/pages/environmental-impact, accessed November 2017

[5] McKinsey, “Moving towards a circular economy”, https://www.mckinsey.com/business-functions/sustainability-and-resource-productivity/our-insights/moving-toward-a-circular-economy, accessed November 2017

[6] Natural Resources Defence Council, “NRDC Fibre Selection”, https://www.nrdc.org/sites/default/files/CBD-Fiber-Selection-FS.pdf, accessed November 2017

[7] Tyton BioSciences, “Our technology”, http://www.tytonbio.com/our-technology/, accessed November 2017

Very interesting article with a clear view on the issue.

I truely beleive that it is not enough for companies to react to climate change only to the extent to which it directly impacts their value chain. However, given the current worldwide regulation, if they are the only one to be environmental friendly, it might increase their cost and make them less competitive. So: yes, it is not enough, but they behave in an economical way and thus regulators should force all the players to react to climate change to kill any competitive advantage of not reacting to climate change.

The regulation trend is going on in California for example (1). The local gouvernment is taking care of these issues and is showing interesting results and I truely believe that this kind of regulation should be implemented worldwide.

(1) https://www.cottonfarming.com/current-issue/farmers-seek-clarity-in-rewrite-of-wotus-rule/

This is a very important topic, and I am curious to see how synthetic fibers gain traction and what climate impacts may stem from developing these new materials.

I agree with Marc’s view that large corporations have an obligation to react to climate change as broadly as they are able. Nike has been consuming cotton for decades, and even if they stop consuming fresh raw materials entirely, there is substantial impact from other components of the supply chain. Nike maintains a complex manufacturing system, which feeds into a massive transportation network, both of which rely upon fossil fuels to deliver inventory to retailers. The breadth of investment in climate change mediation by a manufacturing company cannot be capped at raw material efficiency, but rather should include clean automobiles and other clean energy sources.

I agree with U. Bolt above that Nike’s investment in climate change cannot be limited to minimizing/optimizing raw material usage. On the point of transportation – how will Nike address its climate impact as it seeks to shorten lead times? Arguably the easiest way for manufacturers to decrease lead times is by choosing air freight (delivery in only a couple days) over vessel freight (delivery by ship that takes several weeks). This has cost implications of course, an incentive to not immediately switch to the higher emissions method of transport. But I do wonder whether Nike is targeting raw materials usage because it is the highest impact area / biggest area of exposure, or whether it is simply the easiest for them to tackle without significantly increasing COGS…

In either case, it’s a good place to start!

Interesting thoughts. I commend Nike for working towards a zero-carbon footprint. So far, I favor their initiatives compared to their competitor. Adidas partnered with Parley to create some good-looking shoes made with ocean plastic. I remember seeing pictures of the shoes cycling through social media last year. I couldn’t believe the price (and enthusiasm) – I think they started at over $200 per pair. It looks like that price has come down a bit, but the entire initiative rubbed me the wrong way. It was clear that Adidas was capitalizing on a “feel good” story. Most of us don’t like to see our beaches crowded with litter, but the most efficient way for a shoe company to solve that problem isn’t to spend an exorbitant amount of money incorporating that specific material into their supply chain. In turn, I am almost certain that this product raises Adidas’s carbon footprint through increased inefficiencies and emissions.

Interesting read, thanks for putting it together MC. Quite a few large organizations, including Nike, are working towards initiatives around reduction in greenhouse gas emissions, replenishing aquifers (water positive models), waste treatment etc. While all of their efforts are commendable, I wonder if a primarily for-profit institution can ever run sustainability initiatives that put the environment over economic gain. Some organizations claim to hold themselves accountable to “double bottomlines” or “triple bottomlines” – but more often than not, a skeptic can argue that given the lack of real regulatory frameworks and enforcement such sustainability initiatives fail to make a meaningful impact. What are some interesting approaches that governments/trade bodies have adopted to incentivize organizations to pay as much attention to environmental initiatives as they do to initiatives purely for financial gain. Can such regulations go beyond just environmental conservation/replenishment initiatives to include social impact initiatives?