Can Nike use 3D-printing to sustainably mass customize its offer to consumers?

As pressure to achieve efficiencies while improving product quality is on the rise, Nike is exploring whether 3D-printing can be the answer to manufacture the products that best support athletes' performances

Context and challenge

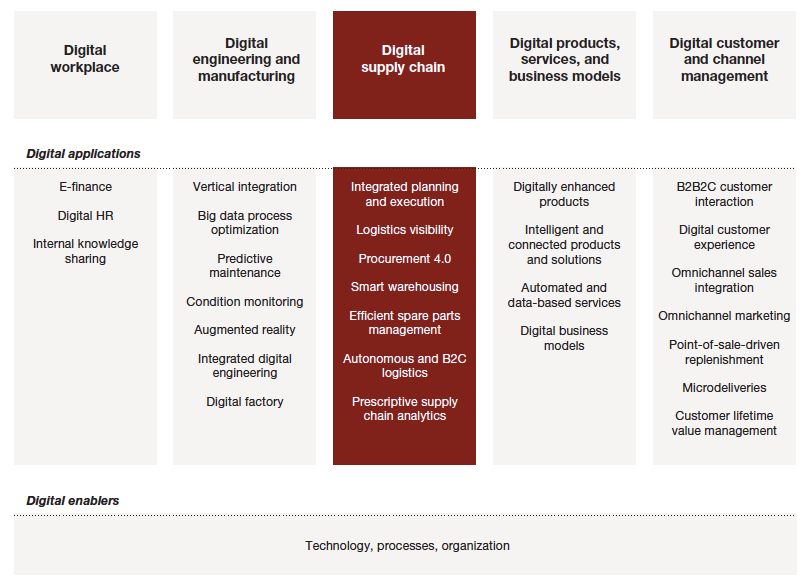

Supply chain 4.0 presents itself as both the next great opportunity and challenge for companies in multiple industries, with the development procurement 4.0, smart warehousing, efficient spare parts management, among other dimensions1,2.

Figure 1 – The supply chain at the center of the digital enterprise – Strategy& analysis2

As companies focus increasingly on efficiency and sustainability as a source of competitiveness, 3D-printing can be a tremendous differentiator, allowing to transform manufacturing flexibility, drastically reducing development time, eliminating tooling costs and simplifying production runs, while at the same time making it possible to create complex shapes that weren’t feasible before3,4. As an early adopter of sustainability practices, both from corporate responsibility and efficiency perspectives, Nike continues to be one of the pioneers in this field, however, competition is not lagging behind5.

Nike’s journey

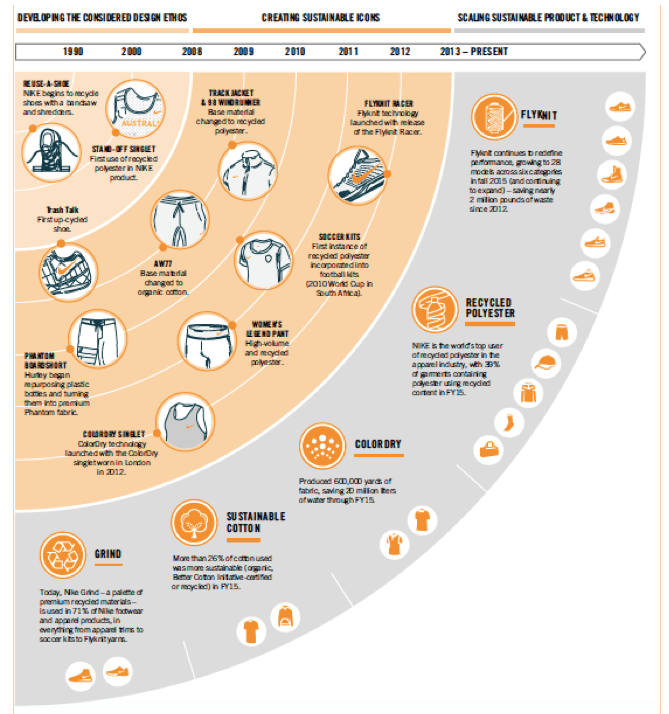

With the focus on sustainability and advancing its supply chain, Nike has developed and incorporated numerous technologies, ranging from raw materials sourcing to process and manufacturing6.

Figure 2 – Scaling sustainable innovation – Nike’s Sustainable Business Report6

One of its most famous technologies is the NIKE Flyknit technology, which has disrupted the traditional method of making shoes and enabled designers to microengineer every stitch of an upper, reducing waste by about 60% on average compared to cut and sew footwear. NIKE Flyknit has grown from one model in 2012 to 28 models across six categories in fall 2015, and has continued to expand, reducing nearly 3.5 million pounds of waste6,7.

Figure 3 – Fours years of Nike Flyknit – Infographic7

Nike furthered developed the Flyknit technology by pushing it to 3D-printing in the development of running shoes for gold-medal-winning American sprinter Allyson Felix. For the 2016 Olympics, Nike used research from its Nike’s Sports Research Lab, leveraging data, testing by Felix, and feedback from her coaches to precisely adapt the key elements of strength, fit and flex to Felix’s specifications and biomechanics. 3D-printing allowed to tailor the fit to the unique contours of Felix’s foot and preferences, reducing sampling time from weeks to days, enabling immediate feedback, quick iteration and, fundamentally, creating a better final product, completely customized for the athlete optimized performance8.

After over three years of innovation in the 3D-printing and Selective Laser Sintering space, Nike was in 2016 already able to make and tweak prototypes in hours, instead of months. In May 2016, aiming to take 3D prototyping to the next level, Nike announced a partnership with HP, shooting for a faster and smoother prototyping pace. Tom Clarke, President of Nike Innovation, said that the partnership would allow Nike “to accelerate and scale our existing capabilities as we continue to explore new ways to manufacture performance products to help athletes reach their full potential.”9.

Competition and next steps

For Nike to continue as a leader in sustainability and digital supply chain, especially in the 3D-printing sphere it will inevitably need to scale and show customers and competitors its commitment to an advanced supply chain, moving from trials to production at scale. Adidas has already taken some key steps in this direction, launching a sneaker with a 3D printed sole and plans to mass produce it from 2018, reacting faster to individuals’ customized preferences – from design and color to weight10.

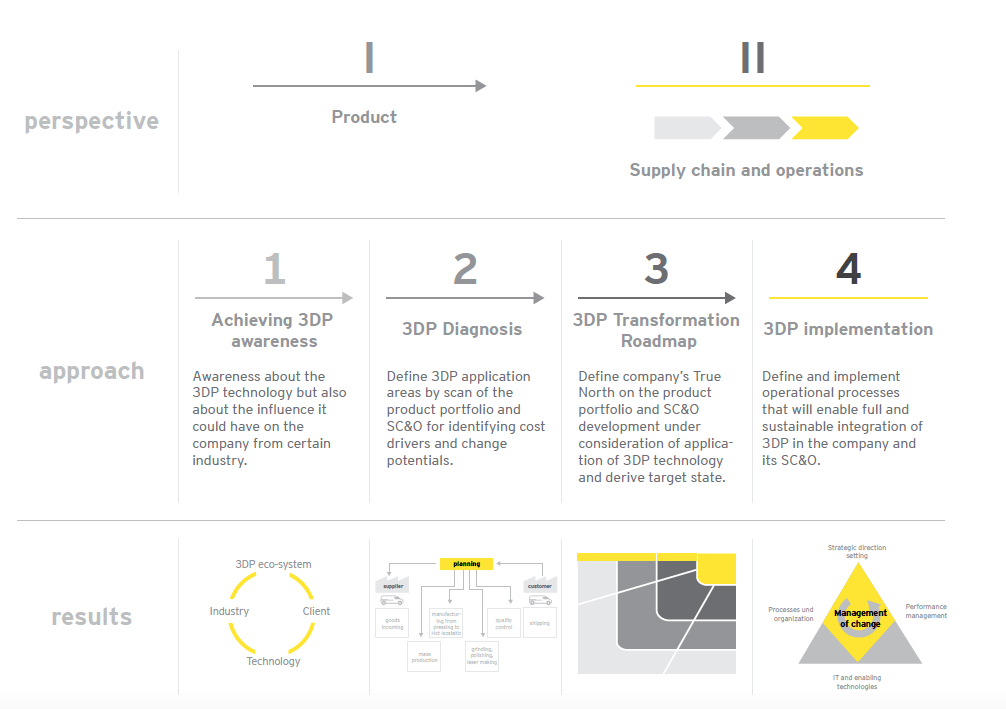

Furthermore, this cannot be a single movement within Nike, but a broader organizational awareness, with skill development and implementation. EY suggests a four-step approach on how companies can create and spread this 3D-printing ecosystem4.

Figure 4 – 3D-printing four-phased approach – EY4

Finally, considering how 3D-printing could fit into Nike’s overall performance and strategic differentiation, it is crucial that Nike finds the way to integrate its many initiatives – from recycling materials, Colordry and Flyknit technologies and 3D-printing6 – towards a consolidated strategy. In particular, and bearing in mind it is a consumer goods company, Nike needs to think how to bring customers to the discussion5. If not careful, 3D-printing could lead to increase costs instead of realized efficiencies, leading to consumer disappointed, similar to what happened with its self-lacing Nike HyperAdapt 1.0 when it was announced to retail at $720 in late 20165,11.

In an organization with such a rich sustainability and innovation culture, alongside a great focus in product development and customer centricity, Nike needs to effectively communicate, both internally and externally, how its many dimensions are connected, and how they allow Nike to offer a more sustainable, efficient and high-quality product.

How can Nike integrate 3D-printing into its overall sustainability and supply chain digitization strategy, achieving cost and waste efficiencies? Should Nike scale 3D-printing into mass production to remain competitive? If so, when and how? How can Nike balance the tradeoffs and investments between cutting-edge athlete performance enhancement products and mass production, yet potentially less complex, affordable customization?

Word count: 794

Sources:

1 McKinsey (2017) “Supply Chain 4.0 in consumer goods” Available at: https://www.mckinsey.com/industries/consumer-packaged-goods/our-insights/supply-chain-4-0-in-consumer-goods (Accessed: November 7, 2017)

2 PWC Strategy& (2016), “How digitization makes the supply chain more efficient, agile, and customer-focused” https://www.strategyand.pwc.com/reports/industry4.0 (Accessed: November 7, 2017)

3 McKinsey & Company (2014) “3-D printing takes shape” https://www.mckinsey.com/business-functions/operations/our-insights/3-d-printing-takes-shape (Accessed: November 7, 2017)

4 EY (2016) “If 3D printing has changed the industries of tomorrow, how can your organization get ready today?” Available at: http://www.ey.com/Publication/vwLUAssets/ey-3d-printing-report/$FILE/ey-3d-printing-report.pdf (Accessed: November 7, 2017)

5 Banks, A. (2016) “Who Is Winning the 3D Printing Battle in Footwear & Why?”, High Snobiety. Available at: https://www.highsnobiety.com/2016/12/15/3d-printed-shoes-nike-adidas/ (Accessed: November 7, 2017)

6 Nike FY14/15 Sustainable Business Report (2016). Available at: https://s3.amazonaws.com/nikeinc/assets/56356/NIKE_FY14-15_Sustainable_Business_Report.pdf (Accessed: November 7, 2017)

7 Nike (2016) “Four years of Nike Flyknit” Available at: https://news.nike.com/news/four-years-of-nike-flyknit (Accessed: November 7, 2017)

8 Nike (2016) “Nike Zoom Superfly Flyknit” Available at: https://news.nike.com/news/allyson-felix-track-spike (Accessed: November 7, 2017)

9 Nike (2016) “At Nike the future is faster, and it’s 3D” Available at: https://news.nike.com/news/nike-hp-3d-printing (Accessed: November 7, 2017)

10 Michalska, A., Thomasson, E. (2017) “Adidas to Mass-Produce 3D-Printed Shoes” Available at: https://www.businessoffashion.com/articles/news-analysis/adidas-to-mass-produce-3d-printed-shoes (Accessed: November 7, 2017)

11 Pearson, D. (2016) “Nike’s Self-Lacing Hyperadapt 1.0 Is Releasing Next Month & Will Cost $720” Available at: https://www.highsnobiety.com/2016/11/14/nike-hyperadapt-1-0-price-release-date/ (Accessed: November 7, 2017)

Really interesting read about a topic I’ve thought about quite a bit. One of the things I wonder is how scalable 3-D printing technology is outside of retail production. I’ve read certain use cases of it being used in various manufacturing capacities, but none as compelling as the story Nike has been able to craft. So, even if Nike does become a pioneer for 3-D printing, I wonder how beneficial pioneering the technology will be in the long run. The skeptic in me feels like 3-D printing is very effective for certain use cases, but less so for other industries despite the hype surrounding it.

It seems to me like 3D printing sneakers is a win-win-win for Nike: it allows them to reduce waste, save money, and produce new designs more quickly all at once, so doubling down on this technology should be a no-brainer. However, I think the biggest risk is that Nike is at its heart a fashion company. The Flyknit shoes I’ve seen have a very different look and feel than traditional Nike shoes, and while some might find them attractive now, consumer tastes change quickly. Will the market for Flyknit styles be big enough to support Nike’s massive shoe portfolio, or will the technology advance more to allow many different styles and materials?

Perhaps it would be safer for Nike to first try this out on its less expensive, more commoditized products (e.g. soccer balls, sweatbands, socks) where it can achieve scale on a few high-moving SKUs and even innovate with colors and shapes in ways that traditional manufacturing doesn’t allow, without the same fashion risk.

Really interesting post, particularly to hear that apparel companies are beginning to think about 3D technologies and how they can enhance the consumer’s experience on top of driving supply chain efficiency. I am particularly bullish at Nike’s advantage over competitor brands into incorporating 3D technology into their supply chain in that they already have customization built into their consumer facing operations. They already offer relatively extensive customization (both online and in store) and have successfully “trained” their consumer base to be comfortable with designing their own products.

Interesting to think about how 3D printing impacts apparel operations more broadly 3D printing would enable you to do away with sizing altogether (no need for the current crude method of different sizes when you can make to order bespoke shoes!)

However, I do wonder whether there a danger in offering the ability to “hyper-customize” to consumers may lead to a more confusing experience and paralysis by choice? No doubt consumer choice is good, but only so much choice is good for the average consumer. Optimizing the “bespoke” experience by customer types will be important– 3D printing could offer customization on every metric, but SHOULD you offer it all? Which consumers really want to make every decision?

I really enjoyed this essay, as a good friend of mine is a marketing executive at Nike and he has told me much about the company and issues they face. The question: “How can Nike balance the tradeoffs and investments between cutting-edge athlete performance enhancement products and mass production, yet potentially less complex, affordable customization?” is a great one because I know that they are really struggling with this issue. According to me friend, the time from concept to production of a new line of shoes has not changed markedly in recent years. This is not due to technology per se, but their own internal processes that make the effort so time consuming. So while the company is trying to build efficiencies in production and supply chain, they are not doing much of anything in terms of the human side of the equation and the culture they have inside their campus. It seems some of these giants like Nike are great at implementing the latest and greatest technology advances but are very poor at looking to change the behavioral aspects of their business.

Great article! I have always been a skeptic about 3D printing because of not being sure of how scalable the technology is. By seeing it in the context of Nike, you can see this issue being addressed and get a glimpse of the potential it has. I also agree with Action Bell how this technology and form of digitization is particularly well suited for a company like Nike that already provides a lot of customization abilities to its customers. Like all digitization in various parts of supply chain, the ultimate goal is how can you add more value to the customer, whatever your definition of “value” is.