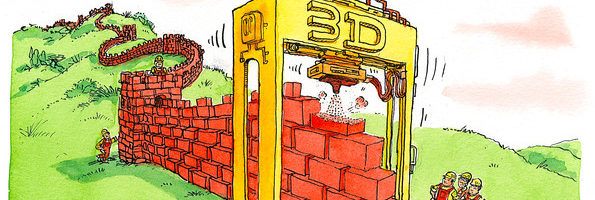

Can a 3D printer solve the world’s housing crisis?

With its towering 40ft printer, currently the largest one in the world, one company aims to do its part to provide affordable housing.

While 3D printing may seem relatively new to many, its conception was only eight years behind that of the inkjet printer. In 1984, Charles Hull invented stereolithography – a printing process that utilizes UV lasers to allow a 3D object to be created from digital data [1]. The basic concept is simple: deposit material in successive layers to create a physical object based on a digital design. Designers, engineers, or architects could now rapidly prototype without the need to invest in large-scale manufacturing. In successive years, advancements in technology have allowed printers to become less expensive, more accurate, and able to print a wider variety of materials (think blood vessels!). 3D printing has exploded into all sorts of industries, from aviation and aerospace to medical and construction.

The application of 3D printing in the construction industry is particularly salient. Habitat for Humanity estimates that 1.6 billion people currently live in substandard housing, and 4 billion people will require affordable housing in the next 15 years [2]. Nearly 100,000 housing units would need to be built daily to meet that demand.

Founded in 2012, the mission of World’s Advanced Saving Project (WASP) is to use technology for sustainable progress. WASP decided to tackle the problem of affordable housing via 3D printing technology by creating the largest 3D printer in the world with the aim of creating a ‘zero-mile’ home [3].

Nicknamed the Big Delta and standing at 40ft tall by 20ft wide, the printer uses, clay, mud, and plant fibers as raw materials to print structures. The choice of material was a conscious decision; not only does mud reduce the environmental footprint of the process by removing the need to source cement, it also acts as a natural insulator. The Big Delta can run on less than 100 watts of power – essentially a few solar panels [4]. For portability, the entire printer can be disassembled and easily reassembled by three people in about an hour. In terms of efficiencies, the Big Delta can lay down between 60cm to 1m of material every day at an estimated cost of 48 euros for a whole structure [5].

Currently, the Big Delta is in Massa Lombarda in Italy, WASP’s home country, where it is completing its first structure. While the final houses are by no means glamorous, the low cost, portable, and sustainable aspects of the printer are huge upsides in rural areas of developing countries. Alternatively, it can also be utilized to provide temporary shelters after natural disasters.

Currently, the Big Delta is in Massa Lombarda in Italy, WASP’s home country, where it is completing its first structure. While the final houses are by no means glamorous, the low cost, portable, and sustainable aspects of the printer are huge upsides in rural areas of developing countries. Alternatively, it can also be utilized to provide temporary shelters after natural disasters.

WASP funded the Big Delta by using proceeds from sales of its commercial printers and continues to be self-financed. The company currently works on an Open Source platform and actively looks for collaborators to partner with them on new initiatives. In the long run, WASP hopes to sell printed structures to individuals and businesses to fund their plans to build 3D houses in developing nations [6].

While the implications of this technology are certainly exciting and can add tremendous value, there are several things that WASP can do in its operating model to ensure it delivers on its value proposition. First, the company does not seem to have partnered with any organizations that are leaders in the non-profit space or any governments on the local or federal level. These organizations would likely be very interested in this technology and could benefit greatly from its application. Additionally, these organizations would likely be able to provide in-depth knowledge on local living conditions, possible challenges, and ideas for adaptation of the structures to the climate or culture of a particular location. Second, WASP needs to continue investing in research to develop new materials or to refine the Big Delta to be able to work more quickly. The impact of the Big Delta is currently limited by its speed, and any incremental improvement will exponentially increase its value as a construction tool. Finally, while WASP is currently self-financed, it should consider the possibility of obtaining outside investment to continue to expand its reach and the scope of the project. Once the Big Delta is firmly established as a functional technology, WASP should be able to tap into financial markets to access a larger pool of capital. While it should be selective about potential investors to ensure that they are aligned with WASP’s main mission, an inflow of capital can open up new possibilities that allow the company to advance its goals more rapidly. With a little luck, in a few years’ time we may be able to see an entire village built by the Big Delta.

[756 words]

Cited Sources

[1] Redshift. 2016. History of 3D Printing: It’s Older Than You Think. [ONLINE] Available at: https://redshift.autodesk.com/history-of-3d-printing/. [Accessed 17 November 2016]

[2] Discovery. 2016. This Colossal 3-D Printer Can Sustainably Print Entire Houses | Discovery Blog | Discovery. [ONLINE] Available at: http://www.discovery.com/dscovrd/tech/colossal-3-d-printer-can-sustainably-print-entire-houses. [Accessed 17 November 2016].

[3] Company – WASProject | World’s Advanced Saving Project. 2016. Company – WASProject | World’s Advanced Saving Project. [ONLINE] Available at: http://www.wasproject.it/w/en/wasp/. [Accessed 17 November 2016].

[4] Digital Trends. 2016. WASP’s gargantuan ‘Big Delta’ 3D printer stands 40 feet tall, 20 feet wide | Digital Trends. [ONLINE] Available at: http://www.digitaltrends.com/cool-tech/wasp-set-to-unveil-worlds-biggest-delta-3d-printer/#/12. [Accessed 17 November 2016].

[5] The world’s largest Delta 3D printer creates nearly zero-cost homes out of mud | Inhabitat – Green Design, Innovation, Architecture, Green Building. 2016. The world’s largest Delta 3D printer creates nearly zero-cost homes out of mud | Inhabitat – Green Design, Innovation, Architecture, Green Building. [ONLINE] Available at: http://inhabitat.com/worlds-largest-delta-style-3d-printer-can-print-nearly-zero-cost-housing-out-of-mud/. [Accessed 18 November 2016].

[6] 3DPrint.com. 2016. WASP Plans to Demonstrate New 6 Meter Tall 3D House Printer This Week: Will 3D print houses in developing countries next! | 3DPrint.com. [ONLINE] Available at: https://3dprint.com/17179/wasp-3d-printed-houses/. [Accessed 18 November 2016].

SUCH A COOL CONCEPT!

Your analysis of the deficiencies of the business plan are certainly accurate – pairing with an NGO or international organization could certainly yield some much-needed leadership and capital infusion. I think there is room here to integrate this as an initial portion of the structure. Instead of building the whole house from mud products, can it just do structural components? I think a more sellable concept is one where that integrates the insulating mud as a structural component but is eventually covered by recycled materials with a high-end appearance.

Can this product additionally utilize shredded garbage/recycled products? Instead of harvesting local grasses, can shredded plastics be used to create a carbon fiber-esque material?

What a time to be alive, beaups! Big Delta’s speed, portability, raw materials, energy use and cost make it and incredibly exciting prospect. Outside of its current operating model, I wonder if there are any other approaches to building sustainable, cheap, portable housing. Perhaps WASP could build smaller versions of Big Delta that could each put together significant pieces of a house, which could then be assembled. Parallel processes could significantly reduce the time required and increase their output. I agree with dfeldpausch on the building materials, and am also concerned about their durability. Could a mud-based house survive a serious catastrophe or are there more durable materials that would achieve the same goals? Overall, such an amazing model!

Beaups – I agree with TOM on this one. It’s a very cool idea, worth checking out this design podcast about past efforts to build concrete dome houses. It’s a great idea, but from a cultural and artistic perspective it can be hard for people to adjust to such a different shape of residence.

I’d suggest targeting areas where there are traditions of similar types of houses first to build a set of use cases. I’d also be curious to hear about how the company solicits input from local residents about their needs from a design perspective.

http://99percentinvisible.org/episode/bubble-houses/

Oh how lucky we are beaups! My question is more around who ends up paying the 48 euros to build the houses? I can see partnering with NGOs and government organizations to pay to build the houses, but I think it could be hard to find extremely poor homeless families to pay even the minimal 48 euros. I assume also that the low cost of 3D printing using local materials will change somewhat if WASP follows Dan’s idea of using recycled materials to create a more physically attractive house than one built using mud. The scalability of the business and its cost structure will be fascinating as WASP prints more and more houses.

Beau,

To be honest, I’m very skeptical towards this idea for several practical reasons

1/ Houses made of mud easily wash away, wouldn’t it be better to give people durable brick houses?

2/ I don’t see the benefit of this technology over prefab structures. Transport cost might be one if you can do local sourcing but you don’t find the right clay everywhere.

3/ You’re limited to certain shapes (narrower towards the top)

Is it truly a viable innovation?

Thanks,

PJ

I think demonstrating success and establishing a proof of concept here is going to be integral to the long-term viability of an idea of this nature. Learnings and outcomes from the Massa Lombarda project in Italy should give us some insight. In the meantime, could WASP think about partnering with advanced academic institutions with expertise in engineering to conduct further R&D efforts, ensure structural integrity, and continue to innovate? If this idea proves viable, I agree that it should garner the attention of NGOs and governments around the world. Is there a monetization opportunity here as well as a social mission?

Beaups, great great article! I am beyond excited about this initiative, but I question the scale of this model. As someone who has lived in a developing country, I really doubt the need for a mud home. Communities usually get together for a couple of days and help each other build houses. However, depending on the comparative durability of the new houses, this might be a worth while initiative. I think this concept (excluding the material and maybe opting for non-toxic plastic) would work great in developed countries (in socially vulnerable neighborhoods) since materials are not readily available at their convenience (at it is for some developing countries).

Thanks so much for this! It restores my faith in humanity!

Super interesting! Awesome technology. It feels like this application will be limited to emerging markets for a long time. In such places, housing is typically detached from the public infrastructure, so these homes will be a considerable improvement on the status quo. However, in developed markets, the infrastructure will probably be the constraining factor.

This is a very interesting concept for providing housing opportunities. It would be interesting to see the cost structure and scalability implications to deploy such a model to help the world in its housing crisis. Do you have any thoughts on this?