Building the Supply Chain of the future

In an evolving world, Supply Chain service providers need to proactively invest in new technologies to try and avoid obsolescence. Will that be enough?

Machine Learning in the Supply Chain environment

In an era where companies aim to expand globally, one of the many challenges is to develop a reliable supply chain network. Machine learning, combined with the exponential amount of data becoming available every day, helps mitigate the risks and variability along the Supply Chain. Through the use of ML, it now becomes possible to discover patterns in supply chain data by relying on algorithms that identify the most influential levers to build an efficient network, while constantly learning in the process. [1]

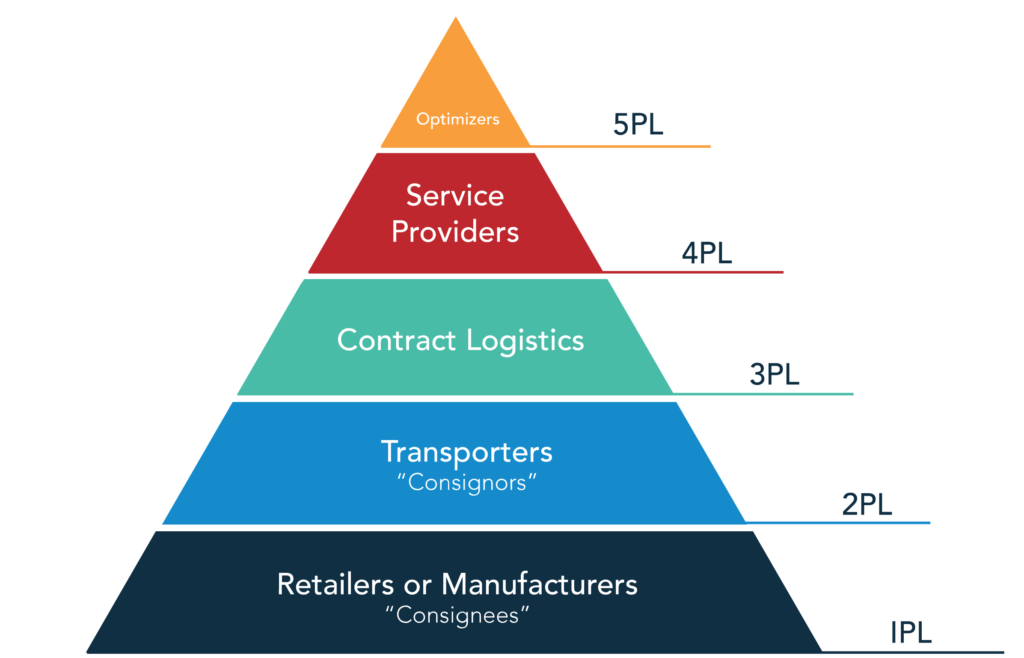

Figure 1: A Comparison Between the Players in the Logistics Network [2]

Fifth Party Logistic service providers (5PL) such as Bollore Logistics are, by definition, hired to develop and implement the best possible supply chains solutions to fit a company’s needs. A 5PL provider will generally aggregate the demands of various companies in term of logistics needs into bulk volume for negotiating more favorable rates with airlines and shipping companies [3]. Bollore Logistics, however and contrary to the standard 5PL that operates without any assets, also offers logistics services through its own fleets of trucks and boats in some countries.

This allows the company to work seamlessly across all levels of the supply chain (see figure 1 above for a comparison of the different levels of services amongst logistics players).

To remain competitive and avoid the risk of obsolescence, the company has no choice but to explore the ML megatrend and to be an early adopter of maturing technologies to improve its network efficiency. Whether the company decides to develop these solutions in-house or to subcontract them is another discussion.

Positioning itself for success

Early on, Bollore Logistics positioned itself as a key player in the digitization race by developing its culture of entrepreneurship. This allowed the company to react in the short-term while positioning itself for the long-term.

The first challenge the company faced was to gather enough data to develop models and feed ML. Bollore Logistics developed its track & trace software – called Link – and its warehouse solution – called Square – in-house enabling the company to offer integrated software solutions along the supply chain. Combining these two solutions, the company offers door to door real-time tracking and tracing while automatically escalating data internally. It is this very data that enables customer profiling and the development of advanced logistics models through ML.

The second challenge is the data analytics and the integration of ML in the company operations. In 2016, the company launched BLab, its innovation laboratory gathering worldwide teams around essential projects with potential for disruption. Using the data assembled for many years, these innovation teams were considering the integration of new technologies within the company’s operating model.

In parallel to fostering innovation, the company integrated ML based solutions to its IT tools. One of them was a Decision Management Platform (DMP), which “optimizes the transport solutions in terms of quality, cost and lead-time, all supported by multiple data sources and predictive analytic techniques”. [4] The DMP platform provided Bollore Logistics with flexibility in anticipating demand fluctuation, in designing flows optimization and in offering alternative and tailor-made logistics scenarios to its customers.

A wide range of challenges

Bollore Logistics is not the only logistics player investing in Machine Learning and innovation. The competition is fierce and companies such as DHL have also developed their own Innovation Centers focused on integrating new technologies within logistics services. [5]

Even though most 5PL and other service logistics provider promote their “innovation showrooms”, it is important to notice that the Supply Chain industry remains an industry based on legacy systems, often lagging behind other industries in term of innovation. In order to effectively reverse this trend and position itself as a leader, Bollore Logistics needs to focus on attracting new talents to develop its R&D departments. The company’s management should be mindful to continue to invest in real improvements and not lose itself in a race for “media attention”.

The company might also consider partnering with key leaders in the technology industry or start-ups exploring the innovation megatrends. Bollore Logistics has a long history of developing solution “in-house” and I strongly believe it could win by working together with some other actors trying to gain a spot in the worldwide logistics market.

A future for Supply Chain Service providers?

Supply Chain, beyond Machine Learning solutions, will be affected by a wide range of new technologies. Facing fully automated warehouses, drone deliveries, autonomous boats, blockchain trackability and others, does Bollore Logistics have a future or do we foresee the development of a decentralized supply chain in the future where every actor would be interdependent?

Is Rolls-Royce future shore control center a possible reality or should 5PL diversify and invest in physical assets to avoid obsolescence?

(778 words)

Sources

[1] Columbus, Louis. “10 Ways Machine Learning Is Revolutionizing Supply Chain Management.” Forbes, Forbes Magazine, 21 June 2018, www.forbes.com/sites/louiscolumbus/2018/06/11/10-ways-machine-learning-is-revolutionizing-supply-chain-management/#5944f3f23e37 [Accessed 10 Nov. 2018]

[2] Cloud Technology Partners. (2018). Keeping the Maritime Shipping Industry Afloat with Automated Logistics – Cloud Technology Partners. [online] Available at: https://www.cloudtp.com/doppler/keeping-the-maritime-shipping-industry-afloat-with-automated-logistics/ [Accessed 12 Nov. 2018].

[3] “Difference between 1PL, 2PL, 3PL, 4PL & 5PL !” LinkedIn, www.linkedin.com/pulse/difference-between-1pl-2pl-3pl-4pl-5pl-chetak-logistics/[Accessed 10 Nov. 2018].

[4] Bollore-logistics.com. (2018). Decision Support and Global Supply Chain | Bolloré Logistics. [online] Available at: https://www.bollore-logistics.com/en/informations-system [Accessed 10 Nov. 2018].

[5] Dhl.com. (2018). DHL | The DHL Innovation Center | English. [online] Available at: http://www.dhl.com/en/about_us/innovation/dhl_innovation_center.html#.W-ntNJNKjD4 [Accessed 10 Nov. 2018].

This article is very interesting given our Beer Game exercise. Are there any other requests by customers, like provide the products just-in-time? Is there any other solutions how machine learning can help to not just accommodate but reduce the variability effects arising from the unpredictable demand and lack of visibility across all levels of supply chain? How does the company differentiate itself from the competitors in this field, as the introduction of high-tech solutions to data analysis is becoming more and more picked up by other players?