Bridgestone: Production System Innovation Through Machine Learning

Increasing product quality while reducing costs through higher productivity leveraging machine learning technology

Background of Bridgestone

Bridgestone, a tire manufacturer from Japan, successfully increased its global share from 7.5% in 1980 to 19.7% in 2000 [1] with superior product quality appreciated by OEMs and customers. Although Bridgestone managed to keep its position as leader since then, share has gradually declined mostly due to increased competition driven by manufacturers from South Korea and China. In 2014, Bridgestone’s share dropped to 14.5% [2], and management team was seeking for new drivers for growth.

Tire as a Product

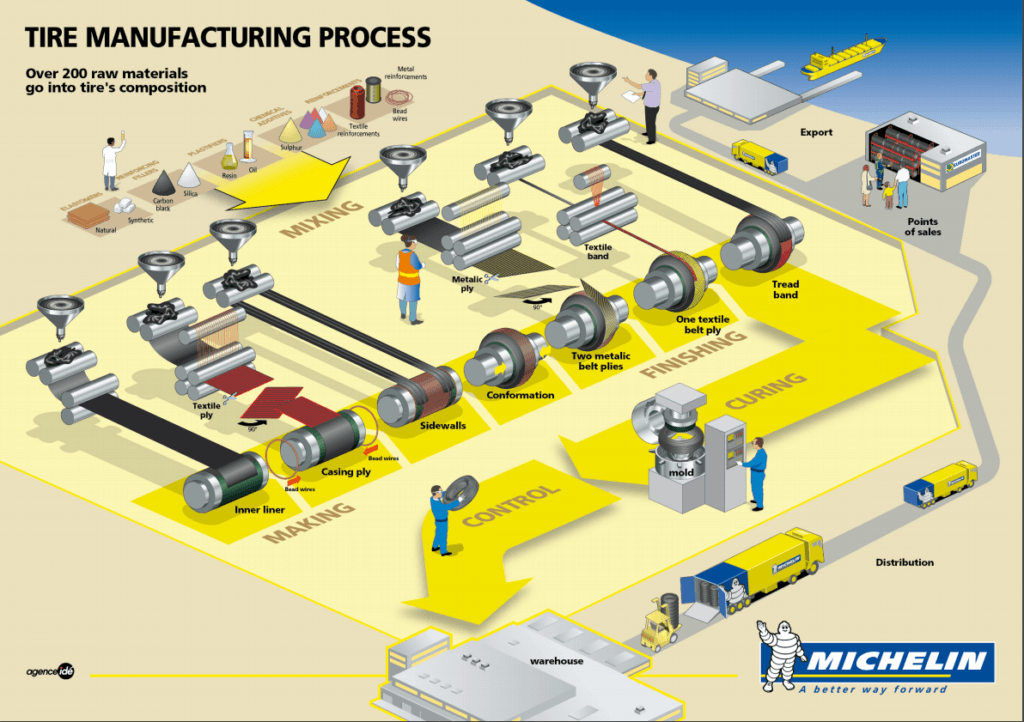

Although tires look extremely simple, the function they need to meet are multi-folded – they need to endure the friction when vehicles drive at 200km/h, cannot leak the high-pressure air inside, cannot slip in rainy and/or snowy days and yet they are expected to be fuel efficient. More importantly, since tires are safety components, perfection was required, not 95% there. With all these factors, rubber as the material has issues where it stretches when temperature is high and shrinks when temperature is low. In the process calling molding (Exhibit 1), the machine stretches strips of rubber while adding pressure to make the round shape. In order to meet all the quality standards, Bridgestone, like any other manufacturer, had to make the adjustment with human’s eyes and hands, and hence, this molding process was always the bottleneck of the entire plant [3].

Innovation in Process Improvement and Product Development

Although the company tried to expand its sales network by acquiring small-size competitors and dealers, the team reverted back to its original strength of manufacturing high quality products with efficient operations. Bridgestone invested in ICT and advanced technology to enhance product quality, and in 2016, it announced its innovative brand-new system, “EXAMATION”. Bridgestone explains the characteristics of EXAMATION as following [4]:

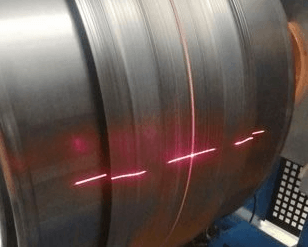

- Higher Product Quality: The system is equipped with machine learning technology that uses sensors to measure quality of the product (Exhibit 2). The quality is measured in 480 items, and the system automatically controls the machine in real time. This process was originally done by humans, and so the uniformity improved by 15%.

- Higher Productivity: As mentioned earlier, the molding process was the bottleneck of the manufacturing line as it required humans. By introducing machine learning and artificial intelligence, the system allowed to remove the human element, and made a significant improvement, reducing the work done to one-third of what it was and productivity doubled [5].

- Less Skill Required: The original production method required human’s hand, so it required training and skill transfer to junior workers. However, by automating the process, it removed the variability related to workers. At the same time workers are still involved by monitoring the system real time and when problems occur, they run over to fix the issue as soon as possible.

An independent jury of 27 top tire industry experts has voted “EXAMATION” as “Tire Manufacturing Innovation of the Year” in the 2017 Tire Technology International Awards for Innovation and Excellence [6]. Through 2020, Bridgestone will invest over 100 USD Million in plants to reform production process. Bridgestone CEO, Masaaki Tsuya, says, “We want to read the times in advance and increase customer value with IT” [7].

Leveraging Data to the Next Level

Komatsu, a giant in the construction machinery industry, has been ahead in fully utilizing data not only for production improvement, but also for higher customer service and customer management. In the system called “Komtrax”, it built in sensors to its products and enable to track all vehicle movement. This “connectivity” allowed Komatsu to better understand the timing to provide replacement items or make the sales representative to meet customers [8].

Tire industry is unique in a way that it maintained a relatively high margin, and sometimes even higher than that of OEMs (Exhibit 3) [9]. However, over the next couple decades, key trends such as, autonomous driving, connected cars, sharing society and electric vehicles, will definitely affect the market [10], and disruptors such as Tesla, Google and others could change the dynamics.

Should traditional players such as Bridgestone stick to its original strength of manufacturing and product development, or do they need to further use technologies such as machine learning in a broader sense to defend its self from distruptors? (702 words)

Exhibit 1 Tire Manufacturing Process [11]

Exhibit 2 Sensors Used for Quality Assurance [12]

Exhibit 3 Bridgestone’s Operating Income [13]

- Bridgestone CEO, Masaaki Tsuya’s Interview; http://dquarterly.com/articles/-/43

- 2017 Global Tire Company Rankings; http://www.tirebusiness.com/article/20170908/DATA/170909961/2017-global-tire-company-rankings

- Bridgestone – Winning by manufacturing in Japan with its “AI Factory”; https://toyokeizai.net/articles/-/153287

- Bridgestone Announces Introduction of EXAMATION State-of-the-Art Tire Assembling System Equipped with Proprietary Manufacturing ICT at Overseas Plant; https://www.bridgestone.com/corporate/news/2016101703.html

- Bridgestone turns to AI for production reforms; https://asia.nikkei.com/Tech-Science/Tech/Bridgestone-turns-to-AI-for-production-reforms

- Bridgestone’s EXAMATION voted “Tire Manufacturing Innovation of the Year 2017”; https://www.bridgestone.eu/corporate/press-releases/2017/02/bridgestone-examation-voted-tire-manufacturing-innovation-of-the-year-2017/

- Bridgestone turns to AI for production reforms; https://asia.nikkei.com/Tech-Science/Tech/Bridgestone-turns-to-AI-for-production-reforms

- Komtrax – Remote Monitoring System; https://www.komatsuamerica.com/service-and-support/komtrax

- Bridgestone – Financial Data: Sales and Income; https://www.bridgestone.com/ir/financialdata/sales/index.html

- Disruptive trends that will transform the auto industry; https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/disruptive-trends-that-will-transform-the-auto-industry

- Exhibit 1 Tire Manufacturing Process; https://thetiredigest.michelin.com/resources/pdf/redirection_document_gb.pdf

- Exhibit 2 Sensors Used for Quality Assurance; https://www.bridgestone.com/corporate/news/2016061301.html

- Exhibit 3 Bridgestone’s Operating Income; https://www.bridgestone.com/ir/financialdata/sales/index.html

Bridgestone’s EXAMINATION system is a really interesting example of the application of machine learning. The successes you mentioned in quality, productivity, and labor are all encouraging factors in the implementation of this technology. This makes me wonder what the next bottleneck will be and if other aspects of their manufacturing process could be improved with automation and increased data measurement. Furthermore, your question of the changing landscape of of transportation is really insightful. It would be interesting to see if, like you mentioned, a product like Komtrax applied to Bridgestone could provide enough data on consumer use to develop machine learning algorithms to help the organization stay ahead of their changing industry.

Interesting to read about the necessity of innovation in a company that I don’t think of when I think “innovation”. The EXAMATION system sounds not just innovative but necessary in the increasingly competitive, quality-driven industry. I’m extremely curious how the implementation of this ML system affects the distribution of human capital – I recognize that it is a critical move to incorporate systems that increase quality and safety rather than rely on human assessment, but how does Bridgestone view its responsibility to the human workforce it is/will inevitably displace? What moral obligation do they have in displacing their workers? Are they responsible (as they are, I’m assuming, one of the first-movers in using ML instead of humans for product quality assessment) for leading the dialogue on the ethics of a decision like this, a decision their competitors will likely have to make as well?