A Perfect Fit: 3D Printing Custom Medical Devices

3D printing is poised to revolutionize supply chains in life sciences. Medical device and pharma giants are preparing to leverage this new technology to deliver customized medical implants with localized, just-in-time (JIT) manufacturing.

Just as the printing press radically transformed the publishing industry, 3D printing is poised to revolutionize supply chains across industries. [1] For life sciences, the potential for impact is especially great. Every person’s body is unique, but medical implants are often only manufactured in a few different shapes and sizes. Frequently, none of the available models are an exact fit for a specific patient, causing additional pain and a longer recovery time.

With recent technological advances, traditional two-dimensional (2D) medical images, such as x-rays, computerized tomography (CT) scans, or magnetic resonance images (MRI), can be converted into digital 3D computer-aided design (CAD) files. These files are sent to 3D printers, which manufacture individualized medical implants, customized to a patient’s particular anatomy.

The adoption of 3D printing in life sciences supply chains is truly a win-win, providing significant value for all constituents. Patients and physicians benefit from using personalized implants rather than using mass-produced products – procedures are more likely to be successful, with shorter time required in surgery and improved patient results. [1]

Manufacturers benefit as well, as this new method of production holds the potential increase cost efficiency and enhance productivity. Today, small-batch or custom implants are expensive due to high setup costs, and it can take months to design, test, manufacture, and deliver each type of product. With 3D printing, digital orders can be sent to local printers and produced within a few hours. [1] This technology facilitates the switch to just-in-time (JIT) manufacturing, reducing inventory and enabling supply chains to be more agile. [2]

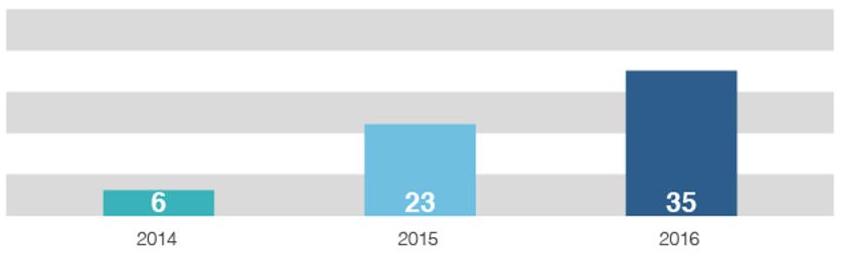

Industry leaders are beginning to jump at this opportunity. Within the past couple of years, the importance of 3D printing has doubled among life science supply chain executives. [3]

3D Printing is Disruptive and Important to Supply Chain Strategy in Healthcare & Pharma

Source: SCM World Chief Supply Chain Officer Survey 2014, 2015, 2016. [3]

Johnson & Johnson (J&J), one of the world’s largest medical device and pharmaceutical manufacturers, is at the forefront of 3D printing innovation. Sam Onukuri, head of J&J’s 3D Printing Center of Excellence, spoke of this initiative at October’s TCT show. In his talk, titled ‘The Power of 3D Printing: How this Technology is Blazing New Medical Frontiers,’ he explained, “We touch almost 1 billion customers every day; our supply chain is very complex… [and] personalized products are a big value for us… from an end-to-end perspective, this will be a lower-cost technology.” [4]

J&J is striving to become an early adopter of this emerging technology by systematically building a pipeline of 3D printed technologies and products. The company is strategically leveraging partnerships with key technology leaders in this space, including Carbon, HP, 3D Systems, Organovo, and Materialise. [5] J&J has also been acquiring technologies, including the recent acquisition of an innovative platform from Tissue Regeneration Systems, Inc. (TRS). This platform can be used to create custom bone-like implants that have a special coating to help the body with absorption and healing: https://www.jnj.com/innovation/trs [6]

Looking towards the future, J&J is aiming for a global impact. In remote areas, such as regions of Africa, China, and India, where there is limited infrastructure to manufacture tools and implants, a small 3D printer could make all the difference. A patient could be scanned at a local clinic, their digital scan sent around the world to have a medical implant reverse-designed at J&J, and then the implant could be printed by a local 3D printer. This allows the delivery of complex, customized medical implants without massive infrastructure investments or long delivery lead times. [7]

Mountains to Climb

While this technology holds great potential, there are many challenges to overcome. J&J is well-positioned with its current focus on building a robust pipeline, and it should continue to push for scientific breakthroughs. Throughout the process, they need to make sure that they are helping regulators to build accurate and beneficial regulation in order to ensure that the speed of development in this new and exciting field doesn’t lead to ineffective quality control procedures. There is a need for testing and certification norms to ensure that patients are never treated with sub-par products.

In order to realize the goals of lower costs and improved access to patient-specific products through distributed 3D printing manufacturing, J&J must also invest heavily in learning how to scale these processes to meet global demand. To truly improve their supply chain, they need to build capabilities to do personalized, localized, JIT manufacturing at scale. Looking forward, J&J will need to ask themselves: How do we capture this incredible potential to deliver customized medical implants, at a lower cost and faster speed, to patients all around the world? There are many mountains to climb as J&J strives to scale this nascent technology to meet the demands of their $1B+ customers.

(776 words)

[1] C. Lee Ventola, “Medical Applications for 3D Printing: Current and Projected Uses,” Pharmacy and Therapeutics, 39 (October 2014): 10, https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4189697/, accessed November 2017.

[2] “The Future of Life Sciences and Healthcare Logistics,” DHL Customer Solutions & Innovation, June 2017, http://www.dhl.com/content/dam/downloads/g0/about_us/logistics_insights/dhl_future_of_lsh_2017.pdf, accessed November 2017.

[3] Kevin O’Marah, “Digitization In Supply Chain: Five Key Trends,” Forbes, November 17, 2016, https://www.forbes.com/sites/kevinomarah/2016/11/17/digitization-in-supply-chain-five-key-trends/#64513e33428a, accessed November 2017.

[4] Clare Scott, “Johnson & Johnson Looks Toward a Future of Personalized Medicine Through 3D Printing,” 3DPrint.com, October 12, 2017, https://3dprint.com/190785/johnson-and-johnson-medicine/, accessed November 2017.

[5] Michael Molitch-Hou, “Johnson & Johnson Adopts Cutting Edge 3D Printing for the Future of Medical Devices,” Engineering.com, September 7, 2016, https://www.engineering.com/3DPrinting/3DPrintingArticles/ArticleID/13063/Johnson-Johnson-Adopts-Cutting-Edge-3D-Printing-for-the-Future-of-Medical-Devices.aspx, accessed November 2017.

[6] Sy Mukherjee, “Johnson & Johnson Wants to Use 3D Printing to Heal Broken Bones,” Fortune, April 20, 2017, http://fortune.com/2017/04/20/johnson-johnson-3d-printing-bones/, accessed November 2017.

[7] Signe Brewster, “The Power of 3-D Printing: How This Technology Is Blazing New Medical Frontiers,” Johnson & Johnson, March 27, 2017, https://www.jnj.com/innovation/how-3D-printing-is-blazing-new-medical-frontiers, accessed November 2017.

Cover photo: https://3dprint.com/82272/what-3d-printing-works/

Very interesting, thanks for sharing. What’s most interesting to me about 3D printing in this application is the opportunity to produce this onsite. I can imagine a world where hospitals perform procedures, but also print their own implants (using J&J machines). What’s also interesting is this expertise in 3D printing for medical purposes could one day lead to printing organic material (like replacement organs).

The importance of 3-D printing in under-resourced societies is a very potent point to consider. If the technology is effectively dispersed in a broad and accessible way, it seems to have the potential to fill gaps in global supply chains by delivering specialized manufacturing knowledge and capacity without having to import or home-grow specialists. I can see demand shifting from a need for specialized manufacturers, and towards a new class of professionals specifically trained to maintain and quality control 3-D printing operations in many different fields.

From a marketing perspective it’s also interesting to think of 3-D printing becoming a key competitive advantage for companies that can get it right to be able to market themselves on increasingly personalized products outside of medicine. (Jewelry and other wearables come to mind).

Loved this essay! I see so much potential in 3D printing too. As the price of entry gets lower and lower, there are some other interesting avenues which 3D printing is exploring. One I’ve seen is the use of 3D printing to print exact replicas of broken bones in personal injury law suits. Convincing a jury by showing an X-ray is one thing. Being able to make them hold a 3D printed replica of the exact bones fracture suffered by the plaintiff is much more convincing. It’s a brave new world out there!

Very interesting article Marissa! I see the disruptive potential that 3D printing can have in the medical devices sector. My big concern here would be that regulatory bodies in the healthcare space have to be very strict with all and each commercialized product, and I can see challenges with regulators accepting thousands of different customized products without testing them, which of course would be ridiculous. I think companies like J&J will have to do a lot of work in educating regulators and lobbying with them so that they don’t become the bottleneck, and this might require a considerable amount of investment from the companies’ side.

Thanks for the article, Marissa! The rate at which medical technology is advancing is astounding, and I was glad to learn that J&J is hoping to deliver this technology to developing markets. One thing I do wonder about is how economically feasible the personalized, JIT production system will be, especially if the medical parts have to be delivered across the world. I wonder how J&J (or any other company) might work with local markets to streamline the cost of delivery and implantation of these 3-D printed devices. One thought I had is that local markets could develop their own “hubs” where parts would be delivered and implanted in order to allow for bundled ordering and possibly leverage some economies of scales.

This is super interesting. In a healthcare world where technology advancements have ironically most served to make healthcare more expensive instead of cost saving, I see a lot of potential in 3D printing. I can see 3D printing as a competitive advantage provided the companies that use them are able to integrate them smoothly into their current operations. I completely agree with your assessment of challenges with regulators and getting buy-in from other stakeholders who could be a bottleneck to the quality control aspect of 3D printing. I could see issues with privacy in information sharing and other various regulations as a barrier, but I think the advantages of efficiently using 3D printing for potentially printing live saving organs in the future are far too large to be ignored.

Thank you for sharing your thoughts in this article. I also agree that the opportunity 3D printing presents in the medical industry is huge. I know that advancements have been made to decrease the cost of customized prosthesis, which now enables them to more directly compete with less advanced offerings; but I would be interested to see how the cost of 3D printing implants and other medical devices has changed over time in relation to their legacy alternatives. I think as the technology advances these costs can only decrease, which enables companies not only to reduce inventory carrying costs of such devices but enables for customization to better serve customers. The question I have is whether this will be gradual with the continued penetration of 3D printing technology in the overall marketplace, or if there is some catalyst in the medical industry that will enable these devices to advance at a faster pace.

Thanks Marissa this article was so uplifting. You touched on J&J’s global focus and how the technology can help in remote areas too but I’m curious what the capex vs operating costs implications are for the technology at present. My guess would be much like the challenge with solar energy, perhaps it is currently only feasible to set up 3D printers where the scale of use makes it cost effective, but I hope we do reach a point where this reduces costs in the developing world too and improves procedures for patients and surgeons, a win-win like you said!

3D printing is a very exciting for medicine. We could even push JIT further: immediately after a surgeon is taking out a tumor in the arm (which cannot be entirely and accurately predicted ahead of time due to differences in surgery skills and judgment), scan the patient, produce the artificial replacement material and put it back into the patient in the same procedure. I think it may be doable to work closely on-site with major hospitals and really meet the demand real-time. This will be very valuable to hospitals since patients do not need to come back to the hospital and increase outcome at the same time.

Very interesting article. 3D printing is most definitely significantly going to alter the supply-chain systems within the med-device industry. From efficiencies in prototyping, product-improvements, and new technology platforms this alters how we think about new product development in healthcare. Regulations are once thing I would be worried about especially with high-risk medical devices. It is curious to think about how in an already strict environment if processes will become more difficult. The FDA will have many new policies coming they’re way.

As a few other commenters mentioned, my primary concern for J&J going forward is their ability to respond to new competitive threats in this industry, particularly in the realm of on-site manufacturing. If a third party is able to release a solution for hospitals to have in house, this could hinder J&J’s ability to remain competitive in this field. Therefore, they should remain diligent when entering this marketplace, keeping an eye on new entrants and using their scale to purchase new threats when appropriate. This would also help their supply chain concerns, and move them to area where they are providing a service rather than having to provide a manufactured product.

Great article! I agree that 3-D printing is going to have a significant impact on supply chains, and it will certainly represent a huge value add for medical technology as well as other industries across the spectrum. One question I have though is how soon we can actually expect this technology to engender significant disruption in industry. Research has been conducted into developing 3-D printing technology for over a decade; while undoubtedly there have been advances, it’s unclear that we should expect genuine disruption anytime soon. Still, once the technology is developed at scale, I agree that supply chains (and many industries) will benefit immensely.

“Looking forward, J&J will need to ask themselves: How do we capture this incredible potential to deliver customized medical implants, at a lower cost and faster speed, to patients all around the world?”

I wholeheartedly agree that digital manufacturing, including “3-D printing” technology, will be a great asset in medicine as technological innovation continues. There are undoubtedly many stakeholders and challenges to consider, including research, manufacturing, testing, and of course, the economic rationale. As we consider how medical device manufacturers, or perhaps their customers–hospitals and even physicians themselves–can utilize a truly digitalized supply chain to offer true medical device customization at low cost, I believe there is a silver lining. In contrast to other industries, such as consumer packaged goods, healthcare is unique in the relative price inelasticity of customers when firms can demonstrate increased efficacy and safety of a new product. As such, it may be important for device manufacturers to identify the disease states and use cases for which hospitals, patients, and even payers have a high willingness to pay (e.g. chronic disease that causes significant lifetime healthcare spend and mortality). Through better understanding the value proposition for varied stakeholders and scenarios in healthcare, the question of how, and to what degree, cost efficiencies in 3-D printing must be achieved to accelerate adoption in medicine may be further elucidated.

Marissa, thanks for this fascinating read. I’m interested in your comments about the potential for 3D printing to significantly reduce the costs associated with manufacturing medical devices. Could this significantly expand access in parts of the world that are currently underserved by medical device technology? According to Market Data Forecast, “the Middle East and Africa [Medical Device 3D Printing] market is projected to reach USD 223.44 million by 2021, at a CAGR of 25.27% from 2016 to 2021.”[1] While it’s unclear what segment of consumers these devices would reach, bringing low-cost medical devices to developing markets is a tantalizing prospect. Of course, robust medical systems – doctors, hospitals, healthcare coverage – will be necessary to expanding the medical device market as well. How to contribute to the development of such supporting infrastructure is something companies like Johnson & Johnson will have to take into account as well.

[1] “Middle East and Africa Medical Device 3D Printing Market is poised to cross USD 223.44 million in 2021,” Nov 3, 2017. https://www.medgadget.com/2017/11/middle-east-and-africa-medical-device-3d-printing-market-is-poised-to-cross-usd-223-44-million-in-2021.html

Thanks for an interesting read. 3-D printing is an exciting frontier, and I’m surprised the technology hasn’t infiltrated the healthcare industry more quickly. I too see the potential for the products to be revolutionary but wonder if companies will still be incentivized, or even able, to patent their medical devices and/or designs? Because 3-D printing offers unparalleled flexibility and design options, I have doubts that medical implant patents will remain relevant. If assumption holds true, how will medical implant companies be incentivized to fund their new products? Will a few major 3-D printing players dominate the market and operate on razor-thin margins? Or will a different dynamic emerge? Your mention of the technology’s pros are valid: reduced costs, global availability, JIT delivery, patient customization, etc. However I am curious what cons we may be missing: Sterility? Product durability? Decreased product innovation?