3-D Printing: Disney’s Latest “Wow Factor”

Disney’s research and invention efforts indicate that the toy industry’s 3-D printing revolutionary shift is on its way

“The toy industry will always look to see if it can use technology to enhance the ‘wow factor’”, John Baulch, publisher of Toy World magazine, told the BBC [1]. While there is no doubt that additive manufacturing (“AM”) has transformed the economics of manufacturing across the automotive, aerospace, medical and consumer industries, this breaking technique still enjoys a niche status in the toy industry. However, the significant research and 3-D printing invention efforts led by The Walt Disney Company (“Disney”), the toy manufacturer and media giant, point that this revolutionary shift is already on its way.

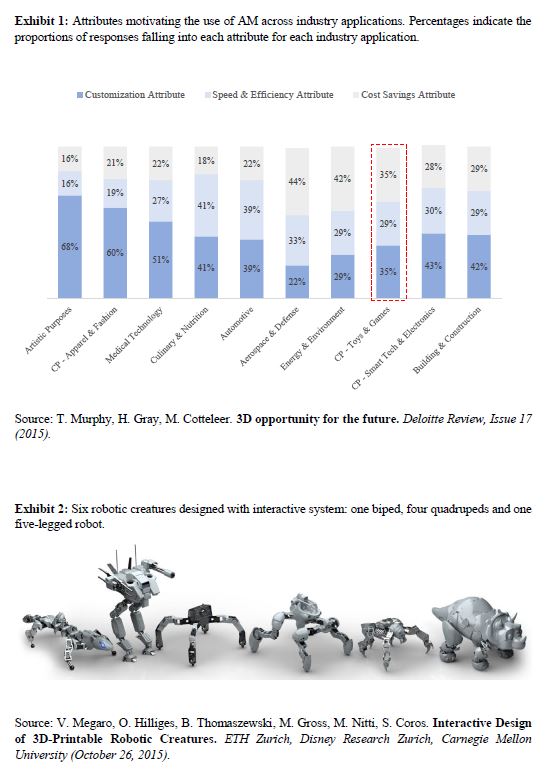

According to Michigan Technology University, the 2020 toy and game industry is estimated to be worth $135 billion, “with 3-D printing bringing those profits home” [2]. As Exhibit 1 shows, this is one of the few industries that enjoys a balanced distribution across the key attributes motivating the use of AM: customization, speed & efficiency, and cost savings. While personalized Disney products for children are popular at theme parks and stores, 3-D printed toys offer more sophisticated customization and can be ordered from home [3]. Furthermore, “although the direct costs of producing goods with these new methods and materials are often higher, the greater flexibility afforded by additive manufacturing means that total costs can be substantially lower [4].”

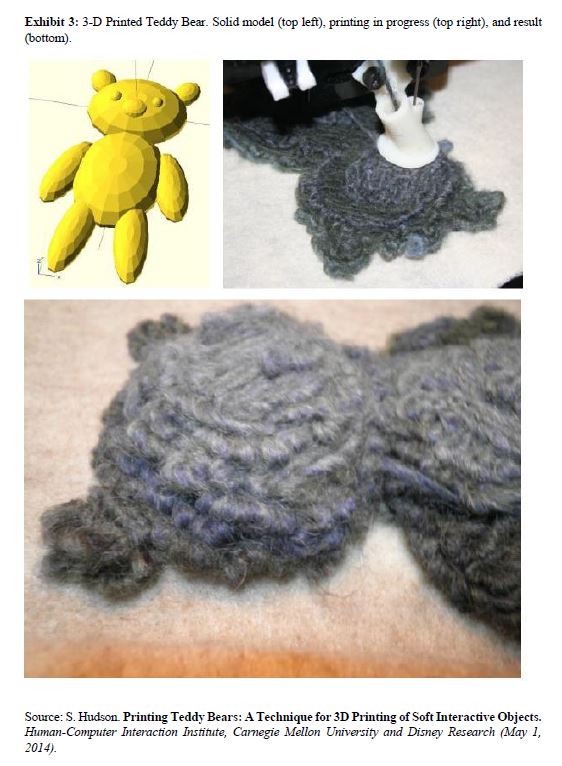

The additive advantage has led Disney to explore the field of 3-D printing. In 2014, the company’s research team designed and manufactured a 3-D printer capable of producing forms from soft fibres, such as wool. This contrasts with AM’s traditional focus on the use of hard materials, such as plastic and metal, to produce objects. Toys manufactured using hard materials could be unsafe for children, given that rough, porous surfaces are hard to sanitize and could be sharp. The use of soft materials “opens up new possibilities in the creation of interactive objects which are soft and flexible, and so more suitable to be worn or simply held close [5].”

Last year, Disney filed a US patent for a 3D-printed, interactive, soft robot. While the patent doesn’t reveal the specific end-use of the robots, it does indicate that they will be interacting with children [6]. The company has also been developing a design system that allows casual users to create 3-D printable robotic creatures, providing ample room for customization. According to Disney’s research team, “the recent progress in 3-D printing technology and the advent of powerful, simple-to program hardware platforms now open the door to a new generation of personal robots – unique companions that we custom design according to our needs and preferences” [7].

Chief Strategy Officer, Kevin Mayer, referred to 3-D printing as “a future technology that’s going to be important to us as a company” [3]. To remain competitive in the medium to long term, Disney is investing in and assisting the 3-D printing technologies of young companies. In 2015, Disney struck a licensing deal with MakieLab, a 3-D printed toy manufacturer that allows children to customize dolls’ physical appearance and clothes via their site online. The London-based start-up was acquired by Disney a year later.

Disney’s research arm has also been working with Open Bionics, a prosthetics maker, to develop character-based limbs for children. “The made-to-order devices will resemble Iron Man’s gloves or snowflakes from “Frozen,” for example. The start-up estimates 10,000 children worldwide could benefit from the initial product [3].”

As Disney moves forward with 3-D printing, there are several obstacles that they should anticipate. For instance, the company will have to determine the real cost-competitiveness of product customization. According to the BBC, “so far the small number of other companies that have developed 3D printing methods have found that the resulting products end up being expensive and have targeted them at adult collectors, rather than children, as a result” [1]. Upsurge demand for home-delivered AM products will also spark questions regarding the geographical proximity of the 3-D printing facilities to customer homes, as well as shipping costs.

Disney should also explore additional trademark protections against the threat of copies, given the ease of downloading designs and creating toys at home using AM [1]. According to Deloitte, the toy industry could have sustained up to $15 billion in AM-related intellectual product theft in 2016 [8]. Disney could potentially open-source some of its designs and focus on the unprintable components or encourage the open-source community to design accessories to make the toys more valuable. According to Joshua Pearce, a professor at Michigan Tech, “this is already happening – there are literally millions of free designs” [2].

Despite Disney’s enthusiasm to achieve new levels of innovation, critical questions regarding the viability of AM products remain: Should Disney wait for AM technology to mature before continuing to invest in it? How should Disney determine the optimal combination of traditional and personalized product offerings?

Word Count: 798

Endnotes

[1] D, Lee. Disney develops 3-D printed lighting for toys. BBC News (October 3, 2012).

[2] A, Mills. 3-D Printing Sweeping Toy Industry Off the Shelves. Michigan Technological University (July 20, 2017).

[3] P. Dave. Disney delves further into 3-D printing with Makielab deal on doll outfits. Los Angeles Times (November 27, 2015).

[4] R, D’Aveni. The 3-D Printing Revolution. Harvard Business Review, May 2015 Issue (May, 2015).

[5] S. Hudson. Printing Teddy Bears: A Technique for 3D Printing of Soft Interactive Objects. Human-Computer Interaction Institute, Carnegie Mellon University and Disney Research (May 1, 2014).

[6] NA. Disney files patents to bring humanoid robots to park. Fox News (April 13, 2017).

[7] V. Megaro, O. Hilliges, B. Thomaszewski, M. Gross, M. Nitti, S. Coros. Interactive Design of 3D-Printable Robotic Creatures. ETH Zurich, Disney Research Zurich, Carnegie Mellon University (October 26, 2015).

[8] T. Murphy, H. Gray, M. Cotteleer. 3D opportunity for the future. Deloitte Review, Issue 17 (2015).

You raise some really tough questions with IP infringement and 3D printing. While the company does review YouTube, e.g., for pirated videos, will the company go after those releasing 3D printing instructions for their IP? And, in a world full of illicit 3D printed copies, is there some special characteristic, some ‘magic’ that Disney can imbue in its legitimate product in order to draw demand?

As for your point about how to speed up the 3D printing process – perhaps Disney can incorporate a ‘layer’ of 3D printing onto mass produced product, so that the costs and lead times are reduced. E.g., for a Mickey plush, instead of customizing and 3D printing the entire unit, they could take a preexisting Mickey plush and add specific features with 3D printing.

Lastly, Disney is precious with its IP. How much customization will they really allow? I would guess that the customization would be limited to a select menu of Disney-created options (e.g., for a Mickey plush, create a menu of options with a pirate hat, eyepatch, sorcerers hat, Christmas vest, e.g.) as opposed to consumers designing their own desired customizations.

This was a fascinating application of AM given the potential for customization in the toy industry. I was particularly intrigued by their ability to print soft objects, which, as you point out, has not been explored to the same extent as hard materials. So, to your first question, I think Disney has an opportunity to move quickly and capture a large market in the soft materials AM space and should work to incorporate that technology now. Waiting could allow competitors to enter the space first and Disney could struggle to compete on product quality and cost-effectiveness. Continuing to acquire smaller companies seems to be their best option right now – they can capitalize on existing technology and bring the teams in house to continue development. You also make a good point that they should pursue additional trademark protections to fend off both potential competition and theft which pose a large threat. It is unclear how long this research will take to come to fruition – but I can’t wait to see what they have planned with the “3-D printed, interactive, soft robot”.

About the “3D-printed, interactive, soft robot”, I read a news earlier this year which says that Disney is considering replacing the current costumed characters in Disney parks with the 3D-printed soft robots. In the near future, Disney employees no longer need to wear the heavy costumes. A 3D-printed soft robot can greet, hug and interact with visitors as well, and the material is safe for children.

As to your first question, I agree with Lindsey that Disney needs to move quickly to grab market share before competitors. Surely, in the short term, they may not be able to achieve considerable (or any) profit from this customized 3D-printed toy business, but I think Disney should be the early mover now. Once the 3D-printing market matures and the cost of production decreases due to economies of scale, Disney will be able to make money from this business.

Echoing the comments above, I agree that Disney needs to move quickly into 3D printing to ensure it captures the proper IP before they are acquired by competitors. However, in terms of how they should roll out the 3D technology, I actually think they should roll it out from a brand perspective starting with their Marvel brand. The BBC quote mentioned how most customers who purchase 3D custom toys are adult collectors who can afford the higher price. I think Disney should lean into that trend by applying their 3D tech first to Marvel toys and cosplay, which I assume has a higher percentage of adult clients than traditional Disney brands like Mickey Mouse.

You raise a lot of good points around Disney’s venture into the 3D printing space. I had not considered the risks a company faces in terms of IP infringement as it relies more heavily on creating products using 3D printing. Disney’s IP, in the form of its characters, is one of its most valuable assets and it continues to generate revenue generation after generation. Given this, the need to protect their IP is of the upmost importance to the company. As the domestic and global regulations in the 3D printing space are far from refined, I question whether the risks of IP infringement outweigh any potential benefit from investing in this area.

Great post. I think you bring up a lot of interesting points that ultimately paint a picture of Disney being in a challenging position for determining how to move forward. On the one hand, if Disney doesn’t invest in 3-D toy printing R&D work, other companies will and Disney will be left in the dust. On the other hand, in the long-run, Disney’s investments in 3-D toy printing could move the industry forward significantly but ultimately backfire if parents simply become able to 3-D print free designs they’ve found online at home (e.g. for a Mikey Moose doll instead of a Mickey Mouse doll). The challenge in front of Disney is finding the best way to thread that needle between innovation and democratization in the 3-D toy printing space.

Very good one! – I believe Disney has this “untold” mandate to lead the way by moving forward with AM anyway. I believe this is due to the fact that it is one of the leading entertainment companies in the world, and as Matt pointed out as well, if it doesn’t act accordingly, someone else will do it and take the all shares. And this idea of moving with AM totally resonates with one of the key pillars of Disney’s success – which was “always be improving”. For the challenges ahead, I think Disney has enough history and experience in its repertoire that it can apply to resolve any upcoming problem for this technology moving forward, whether it is marketing, supply chain, sales, or anything else.

Very interesting article and a use case for AM that I would have never considered! The biggest question I take from this article is what is the end game for Disney. I imagine their toy arm is small relative to their core business – namely, media and entertainment. While AM may help them revolutionize the way toys are created for individual children, is printing prosthetic limbs something that is core to their business? While I certainly think the technology is additive to the experience of their customers, it appears to be more of a niche application and one which ultimately will not have a meaningful impact on Disney’s business.