Flowserve’s RedRaven: IIoT

Flowserve’s RedRaven IIoT platforms provides insights into fluid control systems – the future for pumps and valves

We don’t often hear about pumps and valves in conversations about big data and analytics. But using data and analytics in major infrastructure can have real positive impacts and savings to people’s daily lives. Flowserve is one of the world’s largest suppliers of industrial pumps and valves and is leveraging data analytics to help customers better serve every one of us.

What is Flowserve offering?

Flowserve offers an IIoT (Industrial Internet of Things) platform called RedRaven. RedRaven analyzes data collected from wired and wireless sensors to conduct condition monitoring and predictive analytics. These services give industrial customers insights into the current state of equipment and flow controls, insights into why the equipment is behaving in that way, and what can be adjusted to prevent failures.

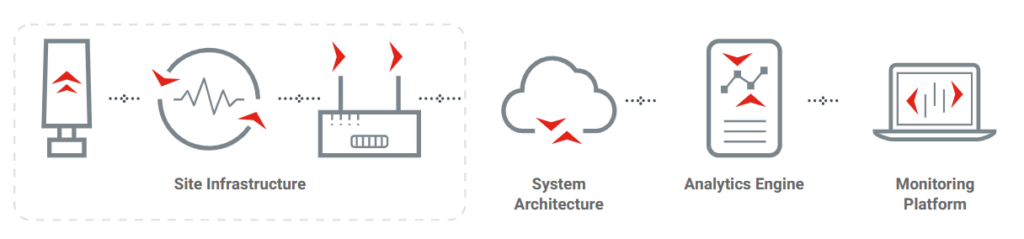

RedRaven is the end of a technology stack starting with on-site infrastructure (meters, sensors, and data collection points), then site-level monitoring systems, then an insight portal where analytics are conducted, and ending with site-level and company level dashboard monitoring systems. While RedRaven is just the analytics platform in this system, it is integrated with other Flowserve and non-Flowserve equipment and services.

How does RedRaven help customers?

In industrial spaces, downtime can be catastrophic. It can lead to interrupted services, lost profits, costly maintenance, equipment damage, and many other issues. RedRaven doesn’t just help companies track and maintain their equipment from all OEMs, it helps them also understand their own production systems through fluid monitoring in real-time.

With RedRaven, customers can identify mechanical, hydraulic, and wear issues with their pumps and valves before scheduled maintenance sessions or equipment runs to failure. Customers can also find areas to invest in for higher productivity and increased efficiency using the platform. RedRaven reduces maintenance costs by 40%, health and safety risks by 14%, and extends asset life by 20%. Thirdly, customers can set production and equipment status thresholds and receive alerts when the system’s processing or equipment’s condition passes a threshold. For example, RedRaven can identify 15 unique types of pump failures which gives incredible operating insights for managers. This reduces the need for constant human monitoring and the data logs help track variations in the system/equipment’s performance.

Flowserve’s complimentary products to RedRaven, such as the live monitoring center lends support to customers with less data sophistication, allowing a variety of customers to benefit from RedRaven.

All of these data-driven insights allow customers to be more in sync with their equipment, reduce laborious monitoring activities, minimize downtime emergencies, and better plan maintenance schedules.

How does this benefit Flowserve?

Flowserve has access to the data collected by customer uses. Insights from the RedRaven platform relating to their products allow Flowserve to take that data into a feedback loop to better design improvements and new products for consumers. This data also allows them to understand how their products are used in different sectors and locations – providing valuable customer and market segmentation data. This helps their sales strategy as well as design improvements. Additionally, with more information about product failures and the conditions that lead to these failures, Flowserve could provide training and maintenance advice to customers who are using the products incorrectly or aggressively.

Finally, with more knowledge about their customers’ failures and equipment needs, Flowserve is able to create value for their customer from an improved aftermarket parts and services offering. Flowserve knows what parts are likely to need to be replaced before they fail due to RedRaven, allowing customers to order relevant parts before equipment fails. This reduces downtime as a company waits for parts to arrive. Analytics from RedRaven also allows Flowserve to recommend different products/parts to purchase if the existing products are not right for the job.

What is Flowserve up against?

Flow serve is playing in an increasing competitive market. Several different OEMs are also offering end-to-end IoT software suites that integrate data from many different inputs.

Customers in this market are price sensitive and often skeptical of these IoT products as the ROI can be difficult to quantify. Leaders at the companies that might use RedRaven might be financially conservative and slow to take up new technologies that have yet to be proven out completely.

Flowserve had to move from being a manufacturer to playing in the digital sphere. They have had to hire, manage, and develop whole new departments and develop a completely new set of expertise. This transition has not been easy for Flowserve, or any OEM for that matter, but it is necessary for these companies to adjust to maintain their market positions for the next 60+ years.

Citations:

- “Flowserve Announces RedRaven, an IoT Services Platform Allowing Asset Management over Sprawling Facilities.” Automation.com, 29 Jan. 2021, www.automation.com/en-us/products/january-2021/flowserve-redraven-iot-services-platform-iot-asset. Accessed 5 Oct. 2022.

- Lim, Charlie. Flowserve Pumps Innovation. 2021.

- “Predictive Analytics | Flowserve.” Www.flowserve.com, www.flowserve.com/en/innovation/iot/predictive-analytics/. Accessed 5 Oct. 2022.

- Rosner, Marla. “The New Industrial Revolution.” Cognitive Times, 2020, pp. 28–36.

- Staff, IVN Editorial. “Flowserve Expands Its RedRaven IoT Solutions for Valves.” Industrial Valve News, 5 Nov. 2021, www.industrialvalvenews.com/featured/flowserve-expands-its-redraven-iot-solutions-for-valves/. Accessed 5 Oct. 2022.

- Zurek, Arik. “Digitization Brings the Ability to Better Respond to Our Fast-Changing World | Flowserve.” Www.flowserve.com, 25 July 2022, www.flowserve.com/en/about-flowserve/blogs/remote-monitoring-systems/digitization-brings-the-ability-to-better-respond-to-our-fast-changing-world/. Accessed 5 Oct. 2022.

I really enjoyed learning about RedRaven through your post. Before reading through what you wrote I had a very limited knowledge of what an industrial internet of things was but your post inspired me to do a bit more research on this concept. I think that the benefit derived from RedRaven’s ability to identify mechanical, hydraulic, and wear issues with their pumps and valves before scheduled maintenance sessions / equipment runs to failure is extremely valuable because it not only decreases the cost of the repair but it also prevents significant downtime in the manufacturing process.