Farm to Data Table: John Deere and Data in Precision Agriculture

Farm equipment manufacturer? Data technology leader? How about both? As the global leader in precision agriculture, John Deere is innovating through the internet of things and data analytics to help farmers improve their operations, bottom line, and ability to feed the world.

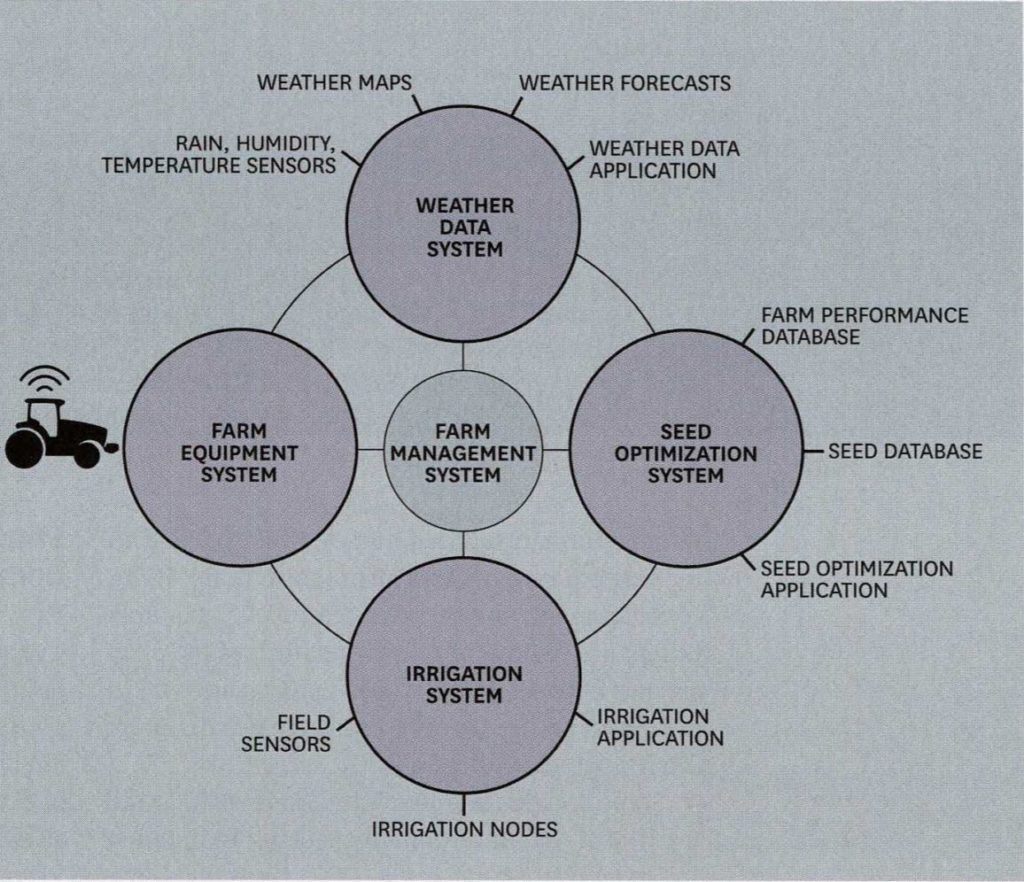

If you’ve ever been to a farm (or even if you haven’t), the name John Deere should recall bright green and yellow tractors plowing across a field of crops. Many people may not realize, however, that these pieces of machinery are part of an IoT for precision agriculture, an intricate ecosystem of data flows across machines, farmers, John Deere, and external partners and the technological infrastructure to facilitate them. Farms are ripe with valuable data to be harvested (no pun intended). In order to maximize yield potential, farmers must consider myriad variables including weather, timing, soil quality, moisture and nutrient levels, seed placement, and frequency and dosage of fertilizer and pesticide application to name just a few.[1] Over the past two plus decades, Deere has been transforming from a pure equipment manufacturer into a data-driven technology company to deliver more value to farmers, helping them to collect data and harness it for improved farm management. The value created for farmers is improved productivity, increased efficiency, decreased downtime, and reduced costs to ultimately maximize profitability.

Precision Agriculture Data as an Asset

Data, including agronomic (crop management) data and machine operation data (e.g., fuel level, location, machine hours, engine RPM) is collected primarily from sensors embedded both in the machines and in the field (soil), but also pulls from external sources (e.g., weather prediction data, commodity pricing).1 Through JDLink™ Connect telematics, the data is automatically uploaded onto the cloud via cellular network, Wifi, or Bluetooth. Farmers access and manage the data through the MyJohnDeere.com portal of the cloud software platform. Through the Operation Center app on this platform, farmers can monitor activity in real-time, analyze performance, determine how best to utilize equipment, and collaborate with partners for insights and “prescriptions” using algorithms that help the farmer decide what to plant, where and when with optimized conditions.[2] Because MyJohnDeere.com is an open data platform, the latter can be accomplished by farmers opting to share their data with apps created by third party Ag software providers leveraging the Deere APIs. The more data that is collected, the more valuable it becomes to all stakeholders – farmers benefit from analyzing data collected over time and from other farmers’ data to inform decisions and Deere and software developers glean more insights paving the way for development of new value-added products and services.[3] Farmers can also share the data with input suppliers (seeds, fertilizer, chemical) to trigger automatic ordering for JIT delivery reducing downtime.

The machine data can also be used by Deere for predictive maintenance. Through machine health monitoring processes and a centralized team, Deere looks at the aggregate of machine data and uses advanced data analytics tools to find patterns that indicate a machine or sensor problem.[4] Remote diagnostics save time and money from technician visits and reduced downtime. Additional upstream value to Deere includes using the data internally to refine products for quality improvement, as well as to advise the next generation of new product and service development.

Investment

Deere has made significant investments in building its internal capabilities around data science and analytics. A team called the Intelligent Solutions Group (ISG) consisting of data scientists and software engineers was created to develop and roll out advanced technology solutions and processes to the four equipment groups under the Ag division. This group has a higher R&D spend than the Deere average and is expected to have its own P&L.1 In August of this year, Deere opened a dedicated, 134,000 square-foot ISG facility in Iowa.[5] By building the technology such as sensors and platform to manage the data in-house, Deere avoids being reliant on others to deliver services to its customers. The company’s latest acquisition of Blue River Technology in 2017 is now powering its entrance into AI and computer vision to “see” and measure data on individual crops with the goal of autonomous decision-making.[6]

Challenges

Managing and integrating all the various pieces of the data systems, processes, and stakeholders has no doubt been highly complex. Key challenges that Deere has faced and continues to face to some degree include:

- Reliable wireless connectivity. The ability to communicate real-time data from machines located in rural areas in a frictionless way was largely dependent on the proliferation of wireless connectivity. Today, all Deere equipment utilizes 4G/LTE modems until 5G is rolled out, but consistent connectivity remains a barrier in developing markets.[7]

- Farmer adoption. Perhaps the greatest challenge Deere faced and continues to face is from the farmers. While the value of data may seem apparent, the cost and complexity of implementing the hardware and programs and learning to use them can slow adoption rates. Farmers require a great deal of support until they reach the point where they can extract maximum value from the data.1 Additionally, farmers that want to maintain control may oppose automated decisions.

- Dealer training. The independent equipment dealers, not only customers, must be trained on using the data and continuously evolving technology in order to sell to and support farmers.

- Data security. Farmer distrust of how the data may be used including market manipulation as well as monetization without compensation is a concern.[8] Furthermore, just as smart phones are hackable, so to is smart farm equipment. This can be ideal for farmers that want to be able to “modify” their own equipment but goes against Deere’s EULA.[9]

Despite the challenges, Deere is leading the path of applying big data in precision agriculture and forging a network of farmers, suppliers, developers giving it a strong competitive advantage suggesting that not only is data the new oil, but data is the new soil to help farmers and their business grow.

[1] Rajiv Lal, Michael E. Porter, and Alexandra Houghtalin, “Precision Agriculture at Deere & Company,” HBS No. 9-717-478 (Boston: Harvard Business School Publishing, 2017).

[2] Matt Hopkins, “John Deere Opens Data Platform to Other Software Suppliers,” PrecisionAg.com, August 30, 2016, https://www.precisionag.com/digital-farming/data-management/john-deere-opens-data-platform-to-other-software-suppliers/, accessed November 2019.

[3] Sunil Gupta, Driving Digital Strategy: A Guide to Reimagining Your Business (Cambridge, MA: Harvard Business Review Press, 2018), p. 28.

[4] “Machine Health,” deere.com, https://www.deere.com/en/construction/construction-technology/machine-health/, accessed November 2019.

[5] “John Deere opens new Intelligent Solutions Group Facility in Urbandale, Iowa,” August 9, 2019, John Deere News Releases, https://www.deere.com/en/our-company/news-and-announcements/news-releases/2019/agriculture/2019aug20-new-urbandale-isg-facility/, accessed November 2019.

[6] Bernard Marr, “The Amazing Ways John Deere Uses AI and Machine Vision to Help Feed 10 Billion People,” Forbes, March 15, 2019, https://www.forbes.com/sites/bernardmarr/2019/03/15/the-amazing-ways-john-deere-uses-ai-and-machine-vision-to-help-feed-10-billion-people/#6e20f0a52ae9, accessed November 2019.

[7] Bernard Marr, “The Incredible Ways John Deere is Using Artificial Intelligence to Transform Farming,” https://www.bernardmarr.com/default.asp?contentID=1387, accessed November 2019.

[8] Rian Wanstreet, “America’s Farmers Are Becoming Prisoners to Agriculture’s Technological Revolution,” Vice, March 8, 2018, https://www.vice.com/en_us/article/a34pp4/john-deere-tractor-hacking-big-data-surveillance, accessed November 2019.

[9] Jason Bloomberg, “John Deere’s Digital Transformation Runs Afoul of Right-To-Repair Movement,” Forbes, April, 30, 2017, https://www.forbes.com/sites/jasonbloomberg/2017/04/30/john-deeres-digital-transformation-runs-afoul-of-right-to-repair-movement/#1a5256ab5ab9, accessed November 2019.

I really liked this post because it touches on an important but often overlooked industry – agribusiness. With the average of a farmer in the US at about 62 yrs old, investing in agricultural productivity makes sense economically and socially speaking. I’d be curious to know if John Deere has reversed its stance on right to repair. If I recall correctly, there was a lawsuit in which the company prohibited farmers from repairing malfunctioning tractors on their own. Perhaps it is in society’s best interest for all these IoT capabilities to be open sourced.

John Deere has been a pioneer in the integration of data sources into its product offering. The Blue River acquisition promises to usher in a new wave of autonomous tractors and agricultural equipment. This seems absolutely necessary if we are going to continue to feed the growing human population. Great work going into the detail of the types of data that farmers can expect to leverage here. It’s a cool story to follow in parallel to the Monsanto blog post!

Great post. You highlighted adoption challenges for this technology, which did not surprise me – it seems like this is yet another industry where we see an “art versus science” tension. Farmers are wary of automation and perhaps concerned that it diminishes the value of their own experience and judgment. I imagine that John Deere will need to invest a lot in educating the farmers on how this technology can enhance their crop yield and business. This feels like a powerful tool, though, and I would guess that those farmers who do adopt data analytics will have an edge.