Drishti: AI-powered Human Production against the Machines

Automation has been slower than you think, over 70% of manufacturing tasks are still performed by humans. Drishti is utilizing AI to empower human operators against the machines.

Automation in the factory floor continues to rise, yet over 72% of manufacturing tasks are still performed by humans. Humans continue to be integral elements of the manufacturing process, capable of performing complex actions that may be difficult for robots to perform (such as those involving a level of dexterity), in addition to providing creative problem-solving and design skills. On the downside, humans error accounts for over 68% of manufacturing defects.

While manufacturing technologies have advanced significantly, the process to gather data in the assembly line continues to be extremely manual. The study above revealed that line manager spent over 37% of their time gathering data manually and performing root cause analyses to trace manufacturing defects. This significantly impacts the time employees spent on other productive tasks.

Drishti combines video and AI to replace the manual process of data capturing in manufacturing to reduce defects and increase process efficiency.

Figure 1: Drishti video capturing. Source: https://drishti.com/

Technology

Drishti’s technical solution encompass two key elements: Drishti Trace and Drishti Flow.

Drishti Trace is the stand-alone video capturing solution that provides insights into all the stations in an assembly line. Drishti Trace enables remote visibility to the entire assembly process, a video database with searching capabilities, video materials for training purposes, amongst other use cases.

Figure 2: Drishti Solutions. Source: https://drishti.com/

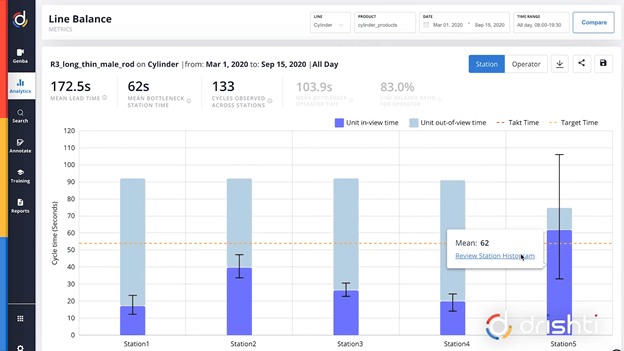

Drishti Flow, on the other hand, is the AI layer that performs advanced analytics on that video to measure cycle time, bottleneck identification, in-state operator feedback, and other performance metrics to improve line performance.

Drishti is fairly easy to deploy, requiring less than 90 days for setup and installation. During the COVID-19 pandemic, Drishti support provided remote guidance for a do-it-yourself experience for their customer. Upon completion of the physical hardware installation, Drishti Trace and Drishti Flow are accessed as an enterprise SaaS subscription over Google Cloud.

Customers

Drishti has developed industry-specific solutions for renowned clients in the auto and medical device manufacturing sectors. In 2020, Drishti concluded a proof of concept with automotive supplier HELLA, where it deployed 12 cameras on an automotive assembly believed to be one of HELLA’s most efficient. Drishti was able to improve productivity on the assembly line by 7%.

Additionally, Drishti has supported several medical device manufacturers during the COVID-19 pandemic to increase efficiencies in their manufacturing operations while cutting travel costs and providing remote access and management via live streams and data analytics from the assembly process.

Besides the examples mentioned above, Drishti serves other renowned customers such as Ford, Nissan, Honeywell, Flex, and DENSO amongst others.

Challenges

In pursuing their global ambitions, Drishti must overcome the following technical and business challenges associated with the industries they are plan and hope to serve:

- Enhancing AI capabilities and KPIs: the current technical solution focuses primarily on cycle time as the metric to optimize. However, video provides a rich set of data that could be captured and analyzed by the AI in the future. Some of the potential data points include hand motion, physical positioning of parts, reaction time, employee’s emotional state, peer-to-peer interaction, etc. All these variables could be analyzed in future iterations of the AI technology to truly maximize the value and impact this technology has on the end customer.

- Diversifying into other industries: As mentioned previously, the company has focused so far on auto and medical device OEMs given the potential that exists within the auto industry with the emergence of autonomous vehicles, and pressure put by the COVID-19 pandemic on the medical devices sector. Diversifying into other industries, however, can be a costly and time-consuming endeavor. In deciding whether and when to diversify to other industries, Drishti must be strategic in foreseeing those industries’ competitive landscape and long-term potential.

- Becoming an alternative to automation: Drishti was founded on the premise that human operators are still involved in over 72% of current manufacturing tasks. However, research has shown that 50% of current activities can be automated by existing demonstrated technology. The surge of automation could weaken the value proposition of Drishti, as human operators are replaced by robots in the manufacturing assembly line. In order to combat this, Drishti should draw comparisons between the added value and return on investment presented by the AI-powered human production presented by Drishti compared to automation technologies.

Figure 3: Performance Metrics. Source: https://drishti.com/

Opportunities Ahead…

The COVID-19 pandemic has validated the value proposition of Drishti. Video and AI technologies have been integral to providing access to isolated factory settings during the pandemic, providing resilience and sustainability to supply chains worldwide. As a result of this, Drishti recently raised a $25M Series B round to scale its operations and take its technology to manufacturers around the world.

Drishti benefits from working with proprietary AI algorithms to process and derive insights from the video they capture. In addition, their hardware-software packaging raises barriers to entry to newcomers, as hardware development typically requires big capital expenditures. As the company grows and collects more data, their machine learning algorithms benefit from deep learning, becoming more accurate and efficient, thus improving Drishti’s competitive advantage.

Additionally, there is an aging manufacturing workforce (one quarter of the workforce is over 55 years old). As this group retires and gets replaced in the upcoming years, video and AI technology will enable knowledge capturing and training of new employees. In a recent survey, 50% of both millennials and Gen Z respondents said they “don’t know how they’d get through life” without video. Drishti could play a critical role in filling that knowledge gap by accelerating their AI-powered operator training capabilities to enable that transition.

Thank you Juan Carlos, very interesting read! Did you see anything related in your research related to worker pushback on being videotaped? I’m not sure about the US, but in other countries there are laws that protect workers against being taped, and have heard of unions also pushing back against this practice.

That is a great question, Rolando. I didn’t really see anything regarding privacy or employment laws preventing Drishti from recording. I could definitely see some tensions in this space — knowing that you are being recording 24/7 could add some tension or anxiety on the side of the employee also, specially if management uses the performance metrics for promotion or firing purposes. I will continue searching for more information on this.

Thanks for this interesting post. I thought Rolando had an interesting point on worker pushback on being recorded. I can imagine it being like a “big brother” scenario, where workers would be so afraid to speak to each other as they know they being recorded. Horror!

I thought you made a really interesting point on how Drishti was built on the assumption that human operators would be involved in most part of the manufacturing process. I wonder if Drishti could go into other non-manufacturing areas where it could add significant value. I can see this being used in education and medical surgery.

This is giving me TOM flashbacks/nightmares. Great post Juan Carlos. Understanding that their challenge may be in expanding to different industries, don’t you think focusing on auto & medical devices is a competitive advantage given how complicated their supply chains are?