Cannabis Potency Measurement using Near-Infrared (NIR) Spectrometry

NIR spectrometry allows fast, non-destructive measurement. Its dependency on data is both a challenge to adoption, as well as an entry barrier for competitors.

As the medicinal value of cannabis becomes more recognized, regulations in the US start to legalize cultivation and trading of this chemically laden plant. As a high-value economical crop, its valuation is not so much tied to its weight, but its potency, which is due to the concentration of psychoactive cannabinoid chemicals. Thus, the accurate measurement of cannabinoid content in cannabis crop became an important process in optimally cultivating and pricing the plant.

While chemical analyses has long been established, it usually takes hours, if not days to complete, and is high in labor and material costs. Its necessary destruction of measurement samples also limits its applications to small sample-size, one-time measurements. Near-Infrared (NIR) Spectrometry, in contrast, is a well-understood alternative to chemical methods, with an almost science-fiction like “scan and read” capability. However, this technology is not without shortcomings. Its need for volumes of calibration data before usage leads to challenges in adoption. However, this weakness can turn into a strength once an NIR technology provider has established a data library, thus presenting tremendous switching cost for customers if a competitor comes in.

NIR spectroscopy systems typically function like this: a beam of light, of which spectrum is known, is shone onto the sample, say, a small plate of cannabis leaves. Some of the light is absorbed by the sample, some scattered, and some reflected. All these lights coming out of the sample was directed to a spectrometer, which measures the spectrum of the resulting light.

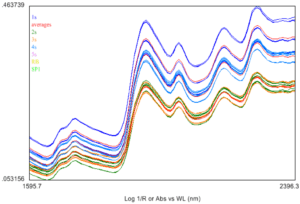

Sample NIR spectrum from multiple scans.

The difference between the measured spectrum and light source spectrum indicates the characteristics of the sample. While the characteristics are visible in a spectrum, they cannot be immediately used to quantify the key parameters measured, like cannabinoid content, moisture, and sugar content, unless a statistical model correlation between the spectrum and actual chemical content.

To build the statistical model, the machine needs to go through a process called “calibration”. The user first needs to collect a range of samples, measure their spectra, and then measure the chemical contents using the traditional methods. The spectral and chemical data are then correlated to establish the statistical model. Once the model is built, the equipment would be able to “scan and read” future samples similar to those used for the calibration. However, when new samples, say, from different species, grown under climate conditions, need to be measured, a new round of calibration needs to be done for the new samples.

The well-known players operating in the IR spectroscopy market include Agilent Technologies, Inc., Bruker Corp., Horiba, Ltd., Jasco Inc., Perkinelmer Inc., Princeton Instruments (PI), Spectra Analysis Instruments Inc., Thermo Fisher Scientific Inc. and FOSS.

Desktop UV-VIS-NIR Spectrometer from Agilent Technologies

Each company has over the years gained footholds in its own market segments, and the switching costs of model-building and calibration limited competitions. First-movers in each segment had to identify a high-value opportunity in order to initiate the first investment in the expensive calibration process. For example, FOSS entered the animal feed measurement application, as it was found that an accurate measurement of protein content could reduce the cost of extra proteins added to the feeds. Multiplied by the sheer volume of the industry, an investment became justified.

Now cannabis presents a new opportunity for most NIR device companies. A “platform war” is at hand as different NIR device providers invest in the data collection, and hope to become the dominant provider in future.

http://www.azom.com/article.aspx?ArticleID=13308

http://kdvr.com/2015/05/14/boulder-company-develops-way-to-test-potency-of-marijuana-instantly/

Thank you for the post Hao. At a high level, how big is the market for this type of cannabis related products? Is there any other applications that this sort of technology could be used for to drive for higher rates of product utilization?