Blue River Technology – innovation in farming that would make even the Egyptians jealous

By focusing on the small things, plant by plant, pixel by pixel, the team of innovators from Blue River Technology revolutionize farming through machine learning and bring this 10000 years old activity into the present with intelligent robotics.

Can you think of an older and more important industry for humanity than farming? Not only it is the activity that changed the course of humanity by altering our behavior from nomads and hunters to gatherers and enabled us to lead longer, safer lives in communities, but it has remained until this day the main activity for sourcing food, essential for the existence of humanity.

“To meet the growing demand, we need to increase our food production by 60% over the next 35 years, which would be an unprecedented pace.” (United Nations)

Farming seems to be the perfect “playground” for machine learning applications, as it presents the need for increased efficiency and productivity (limited and even decreasing space to be used for the benefit of a population that continues to increase), while exposing the experts to a variety of use cases (given the variety of plants and lands, erosion of soil, climate change and unpredictable natural conditions, and increased demand for ecological products). Machine learning can help farmers increase efficiency and accuracy in decision-making while simultaneously minimizing risks and costs associated with agricultural operations. Unsurprisingly, there are already numerous use cases for machine learning in this space, such as: crop management, precision spraying, insect detection, field conditions management, yield mapping, automatic weeding and/ or harvesting robots. You can read here more on general views on the industry and the impact on machine learning.

In this post we will focus our attention on Blue River Technology, a team of innovators who want to radically change agriculture through intelligent machinery.

Meet Jorge and Lee and hear about the beginnings of Blue River Technology:

Blue River Technology started in 2011, when two Stanford graduates Jorge Heraud (the former head of precision agriculture at Trimble) and Lee Redden (a PhD student and roboticist) met and decided to make farming more efficient and sustainable through robotics and computer vision. With an ideal in mind and an infinite pool of possibilities, they decided to engage with their potential end-customers and learn more about pain points to better understand what was the space that could have been viable technically and financially for their future solution. And so, after identifying a customer who was willing to work with them, they identified the first pain point to address: building machines for lettuce thinners (thinning is a traditionally time-intensive and expensive task of eliminating unwanted lettuce seedlings). The lettuce bot automated this arduous process by taking images, identifying which plants to remove, spraying them, and verifying the accuracy and performance of the system, all in real time.

With a prototype constructed, demos started being offered, additional funding secured, and Blue River Technology came to being as a company focused on building smarter equipment to be used in the field to increase yield by making every plant perfect through personalized treatment.

Looking at the example of See & Spray™ Technology we can better understand how Blue River Technology is leveraging machine learning in its operations.

See & Spray machines leverage deep learning to enable machines to identify a greater variety of plant-both crops and weeds-with better accuracy, and then make crop management decisions on the spot. Custom nozzle designs enable plant-by-plant spray resolution, and powerful software powers faster and more agile crop protection. Basically, it is aiming to end the current solution of applying blanket solutions to the entire field, which is making weeds more resistant to herbicides (similar to how more exposure to antibiotics make the bacteria they are supposed to fight against, more resistant to antibiotics) and replace it with a very bespoke yet efficient plant by plant treatment. It is presenting a win-win-win solution: win for the farmer who will cut costs by only applying the right chemicals for the right plants and having higher yields by applying the right treatment at plant level, win for the crops and soil by reducing the amount of chemicals used to treat the crops, helping keep our planet greener, win for the end consumer for eating healthier and less treated food.

There are two parts to the See & Spray machines:

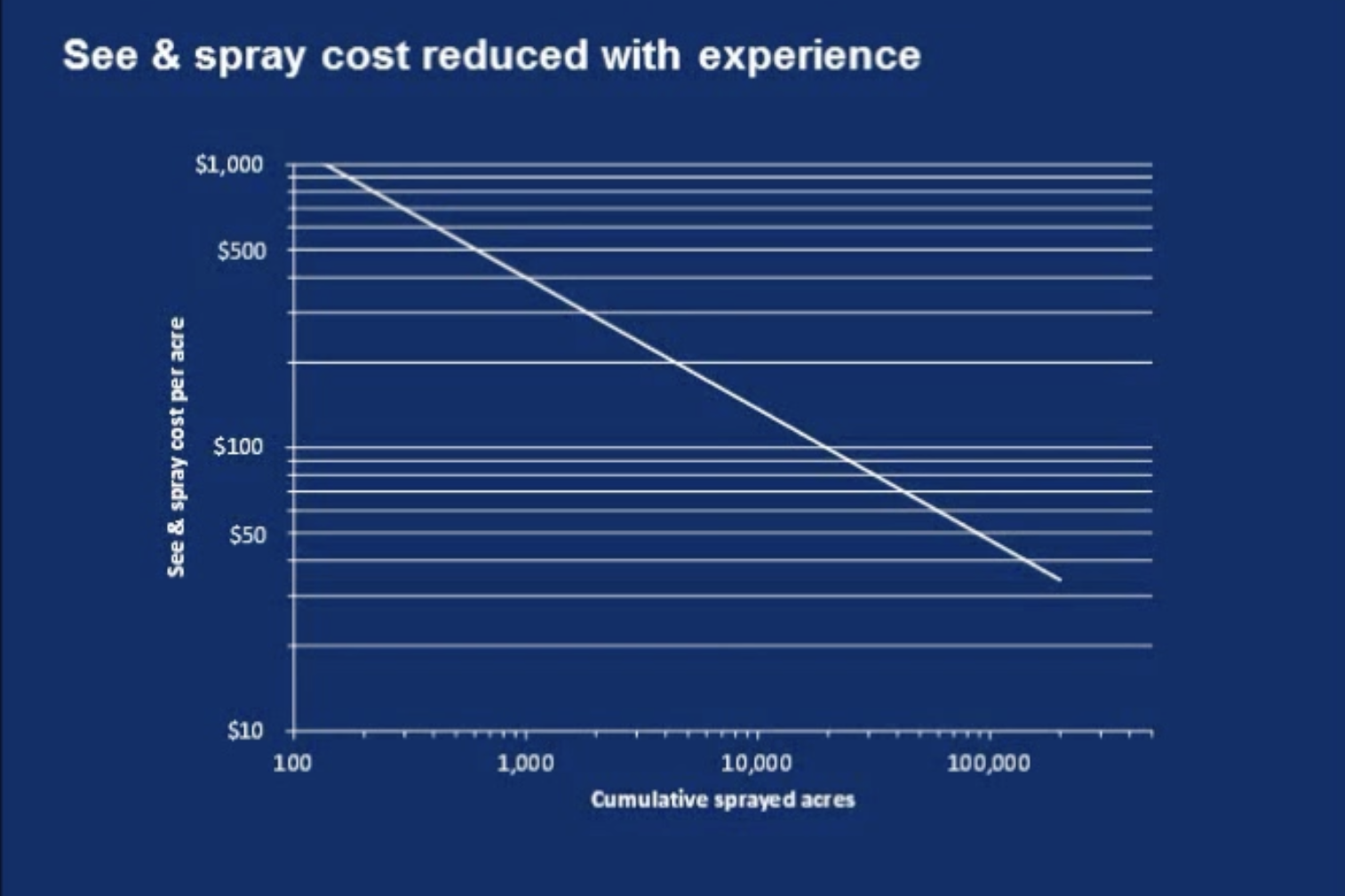

- The “See” element is enabled a comprehensive data base and by incorporated cameras. The data base allows the machine to have a vast repository of crops and weeds in all stages of maturity and health. Cameras will then identify on field, in real time, what type of plant the machine is faced with and the condition the plant is found in. With this type of information available, the machine can make real time decisions as to what type and what quantity of solution to apply at plant level: herbicide, fertilizer, fungicide, insecticide, or other biologicals. Being all driven by machine learning, the more these machines are being used, the better and more efficient they become at servicing farmers. Not only this, but the way the software is programmed, and the machines are built, they allow for multiple experiments on the field, to enable the ideal solution for each farmer and each crop (essential tool, given how weeds have different level of resistance depending on the type of plant, but also on the soil, natural conditions and previous exposure to herbicides. A high level of customization is required to ensure maximum results for each farmer and each crop). As machine learning is as good as the data it is fed, See and Spray was very particular with the way it collected data, starting with corn and once it managed to perfect that it moved into other crops such as cotton, soy, tomatoes, and others.

- The “Spray” part of the machine is essential in enabling the needed results. While the “See” element enables decisions to be made, the “Spray” element is what drives action on field, in real time. Through precision and accuracy, the needed treatment is applied in the right manner, ensuring higher productivity and lower costs. Precision is highly important in this tool, and the team managed to use See and Spray with a 5mm precision level by using multiple cameras to constantly adjust the Spray part of the equipment (to the different levels of roughness of the field, rocks and bumps the machine might encounter in real time), such that the treatment is applied as intended, for the plant targeted. This becomes especially important in the case of herbicide which is not to be sprayed on a healthy crop, damaging the yield level.

Precision is highly important in this tool, and the team managed to use See and Spray with a 5mm precision level by using multiple cameras to constantly adjust the Spray part of the equipment, such that especially herbicide is not sprayed on a healthy crop.

In 2017, Blue River was acquired by John Deere but continues to be run as an independent subsidiary. With the support of John Deere, Blue River is continuing to expand and explore a plethora of innovative new developments to support and empower those linked to the land.

Why did I get excited about Blue River? Because it presents a win-win-win opportunity enabled through AI and ML: keeping food on tables for years to come while optimizing global chemical usage (as it can lead to a 70% reduction in chemicals used) to improve the economic sustainability of farmers.

Thanks, Irina for the wonderful blog! See and Spray use case is one of the most sought-after in precision agriculture since the models can be easily generalized across crop types enabling quick upscaling. It would be interesting to know how they have sourced their datasets up until now and the costs involved therein. Also, what customer land size do their technologies become feasible at since a large part of farming happens in developing countries, where a smaller land parcel size is an issue in the adoption of such advanced technologies? Probably, shared rental solutions can pave the way in such geographies. Thanks once again for the insightful blog!

The blog post covers interesting perspectives on the application of technology in agriculture – seeing and spraying and the win-win-win interactions among consumers, crops, and farmers. I wonder where you see as the next frontier of Agri tech in addition to seeing and spraying?

This is a really interesting post. I am always intrigued by agri-tech solutions and how they can be deployed in the developing world to increase yields. Similar to the leapfrogging we saw with mobile phones, would be interesting to see how this technology deployed on a wide scale would dramatically increase food output and reduce food insecurity for some of the most vulnerable world citizens.