Zara: Fashion at its Fastest

Zara: “How can we make clothes that people actually want to wear”

Company Information

Zara is one of the largest fashion companies in the world. It is the crown jewel of Inditex, one of the world’s largest fashion distribution groups. Zara has over 2000 stores across 88 countries, and their mission statement is “striving to meet the needs of…customers at the same time as helping to inform their ideas, trends and tastes. The idea is to share responsible passion for fashion across a broad spectrum of people, cultures and ages.”

Business Model

Fast Fashion

Zara has a very unique, and at the time of its introduction, relatively revolutionary business model. They coined the term in the industry of “fast fashion”. In fashion there are notoriously long lead times and predetermined production schedules, which cause most designers to plan their collections as far as a year in advance. Zara seeks to have high quality designs at affordable prices, all while refreshing the designs in its stores at least two times a week. This creates a sense of buzz and freshness for customers every single time they walk into a store creating a stark point of differentiation for Zara versus its traditional retail competitors.

Product scarcity to drive sales

By restocking their stores twice a week Zara is are able to hold very little in inventory at each location. This element of their business plan allows them to influence their shoppers purchasing behavior through scarcity principles. Customers are more likely to buy things in the spur of the moment, because unlike with traditional retailers, if they wait the design they like could be out of stock a week later. It also drives further engagement with the company as Zara shoppers visit stores on average 17 times a year versus just 3.5 times for their competition.

Low Ad Spend

This in turn allows them to spend significantly less on advertising. Instead the company funnels what would have been ad spend into high traffic, high visibility, upscale store locations. While the products they offer are reasonably priced, by investing heavily in their stores they create an image of high fashion and quality.

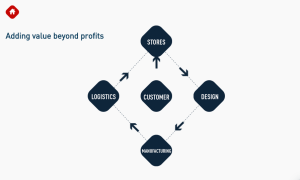

Operating Model

I think that Zara is a great example of a company whose business and operating models are extremely well aligned. Zara’s innovative operating model is the engine that has driven the company to be such an international success. When Amancio Ortega, the founder of Inditex, first created Zara he saw that there were inherit misalignments between most retailers operating and business models. He noticed that the designs his factories were producing never seemed to match what people on the street actually wanted to wear. He came to realize that the objective of a fashion company, should be to make clothes that people want to wear. Its tough to predict fashion trends way in advance so why continue to guess when you can iterate and get it right? In order to make this vision possible he pioneered several operating processes that Zara still uses to this day.

Eschewing the traditional model of seasonal collections and large batch sizes requiring a large reliance on external suppliers, Zara is vertically integrated and produces its most time-sensitive fashion items in-house using very small batch sizes. These items are then shipped to Zara’s central distribution centers in Spain which (for the case of Europe) are very close to their actual stores. Clothes would traditionally stay at the distribution center for only a matter of hours and none longer than three days. By vertically integrating in key elements of the supply chain Zara is able to stay lean and JIT, carefully aligning its production to actual demand in its retail stores. While transportation and logistic costs increase, by controlling multiple elements of the supply chain and virtually eliminating warehousing and storage costs Zara is able to create a sustainable advantage over its peers. Perhaps more critically it also allows designers to push products from the initial design phase to on store shelves in just four weeks.

With this drastic reduction in cycle time Zara’s design team continuously tracks consumer preferences, latest trends, and actual store sales to inform its design process. This involves establishing open communication channels between retail store employees and the design team to ensure that Zara remains consistently on the forefront of latest fashions. So through this operating process they meet the founders original goal, and while limited, the products they stock on the shelves, are clothes that people actually want to wear.

– From what I know to keep up with fashion trends, Zara also uses employees on the store floor to see what people are wearing and base their designs on that, how effective do you think that is?

– In the world of fashion do you expect (like in the world of music and entertainment) that most things that are popular are popular globally with some local twists, or that fashion should be very different region to region? Should Zara Europe be independent from Zara Asia?

Great post Tobi, I’m a long-time Zara fan so it was really interesting to learn more about their operating model. As I read through the post, there were certain tradeoffs that seem to arise through this model. First, in order to quickly manufacture and stock stores with the latest products it seems Zara has to produce the clothing close to its distribution center in Spain which I’m sure would require higher labor costs. Many other stores that focus on new design and quick turnaround for inventory, like Gap, mostly produce their clothing in low labor cost countries lie China. The production tradeoff at Zara seems to be between quick design turnarounds at higher labor/distribution costs. Also, knowing that they have many international store location in the US and in China, it might make more economical sense to have a distribution site outside of Europe that are closer to the markets where they have large market penetration and higher concentration of stores to maximize efficiencies in the distribution network. There could then be a tradeoff in terms of lower overhead costs by optimizing one larger distribution center versus multiple and more diffused/ localized centers that might better allow the company to stock the shelves of stores in international markets more effectively and respond to demand even more quickly.

While their vertically integrated model focuses on JIT and ordering and producing in small batches, I can also see inventory issues still arising as “trendy” goods may be great on the runway but not that wearable or popular in real life. In these scenarios, it would appear that Zara would have difficulty managing inventory that does not sell quickly given the short cycle time that products are allowed to be displayed on the shelf. I would want to know how Zara manages clothing that doesn’t sell in this short time window. I would also be interesting in finding out what analytics Zara uses to predict demand and order the right amount of items at each of their stores. As we saw in the supply chain simulations, predicting demand can be extremely difficult and over ordering and inventory holding costs can have huge financial penalties for Zara stores. I would love to know how or if processes changes as they have undergone massive global expansion.

Yeah – I agree with SR. While there clearly are supply chain advantages, cost savings, and sales benefits with this operating model, I think inventory management could be extremely difficult. As someone who used to buy fashion socks where I would have to commit to inventory without sales history, I would love to know how they determine the quantities to produce for each item. I imagine they can get size-selling percentages from past items (even those change between styles though), but it would be very interesting to see how they determine the quantities for each style. As SR stated, if they buy too much inventory because a style does not sell as well as they thought, Zara would probably need to markdown, salvage, or sell the items to a third party at a significant discount. If Zara has new styles coming in and going out every few days, this unsold inventory will have large margin implications. Also, since these items are on the floor for such a short period of time, Zara does not have much of an opportunity to take pricing or promotional action to move through unproductive inventory. On the flip side, if the items sell out right away (as I am sure some do), the opposite problem occurs where Zara now has additional sales left on the table and an empty space to fill on the floor. I wonder if they tend to be more conservative on their buying strategy to avoid markdowns, and they have have contingency inventory in the backroom that they can flex onto the floor to fill in gaps for items that sold unexpectedly well. Obviously, this model is working very well for them as they are able to capture more sales because their products are more on trend, but it would be really interesting to see how Zara buys its inventory.