WinSun – Print into the Future

Can we build future cities like building LEGO Land?

Vice President and Prime Minister of UAE and Ruler of Dubai announced the “Dubai 3D Printing Strategy” in August of this year. Part of this strategy is to achieve 25% 3D print for all new buildings starting in 2019 at 2% and graduate increase to achieve 25% by 2025. [1]

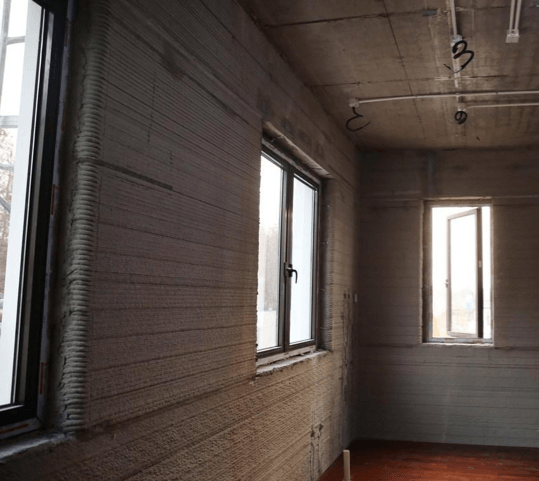

This announcement brought attention to a high-tech 3D print architecture firm in China, WinSun, also known as YingChuang Building Technique (shanghai) Co. Ltd. In 2014 WinSun made the construction headline by printing ten houses in a day under $5000 per house [10]. August 2016, WinSun had completed the first 3D print government building, Office for Future, in Dubai [2][4]. Year later, March of 2017, Saudi Arabian Al Mobty Contracting Company signed $1.5Billion contract with WinSun to lease 100 3D printers and to receive future technique support as well as to access its online cloud platform. [3] As today, WinSun still holds the record of tallest printed building, 6 stories villa, with only 30% of normal construction time [12]

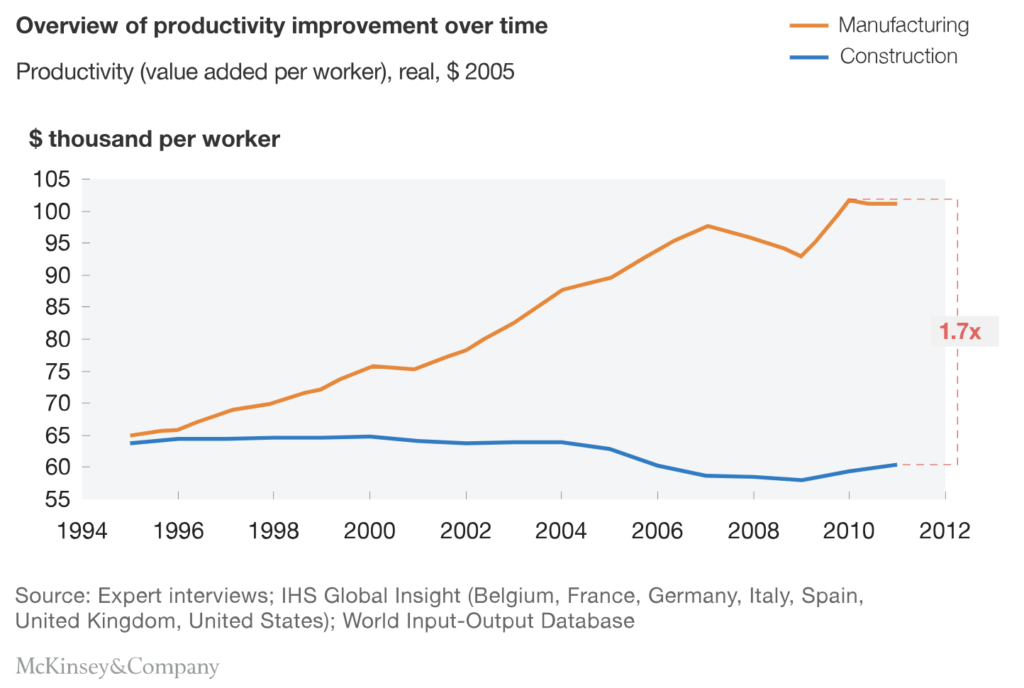

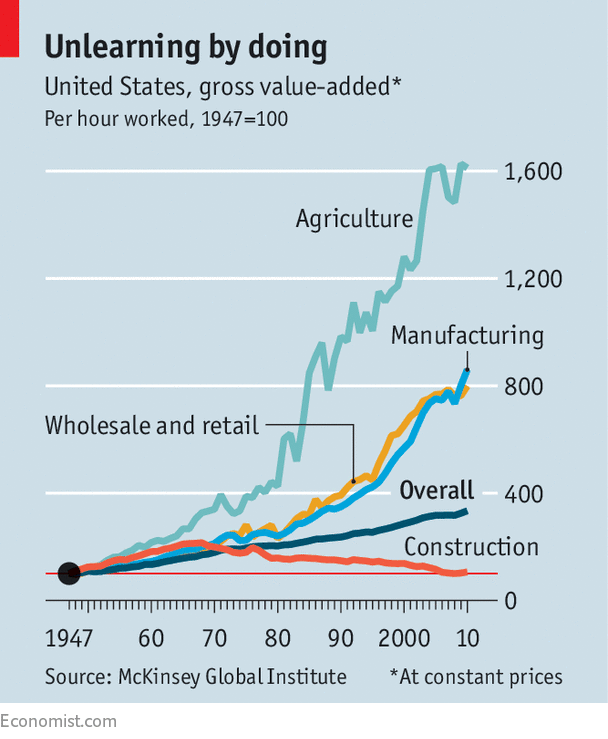

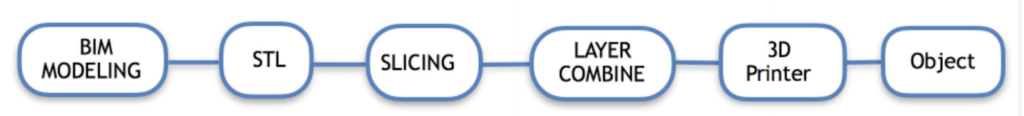

Reference to figure 2 below, the simplify version of 3D printing process, provides answer to the question many construction companies struggled to solve since introducing of BIM – what do we do with this model? How can we effectively translate this model to real productivity?

- It’s environmentally friendly. This construction method not only reduce construction waste by 30% to 60%[10], “ink” from the printer is a special designed mixture that combine industrial recycled solid waste with cement to form much thicker than regular concrete [6].

- Improved safety—Reduce number of injuries and fatalities onsite as the printers will be able to do most hazardous and dangerous works[6]

- Cost Reduction – With reducing profit margin and increasing labor cost while facing shortage of skillful labor, 3D printing can effectively reduce labor cost by 50% to 80% [10] become more competitive and preferable way to build.

- Time saving – Company competitive edge can be further strengthened because 3D printing project reduce time by 50% to 70% [4]. This also adds value to the end users, whether is home owner or developer.

- Encourage diversified working force. By removing labor intensive elements of construction, 3D printing could open possibilities to all people to be integrated into the workforce [11]

- Unrestricted design possibility. Computer automation allows more control and precision while unbound by typical design constrain. The ability to use curvilinear forms, rather than rectilinear form bound by traditional construction, unlocks the door to whole new realm of design [6]

Despite all the great benefits and some early adopters to participate, there are challenges laying ahead:

- Even with high labor cost reduction, up-front cost of the 3D printer is still too high to achieve mass adoption. Printer size and placement still can’t be accommodated for all project types. [8][5]

- There is limitation on types of materials we can use for 3D printing. [8]

- Many skill workers are feared that 3D printers will replace the workforce. [8]

- There is lacking design/inspection standards developed for 3D print components. Although we can apply existing building code, the performance result and testing method maybe different because the design mixtures are new, and we have limited data to understand its long term performance. [5]

Word Count [798]

References

- Malone, D. (2018). Dubai plans to 3D print 25% of every new building by 2025.Building Design & Construction, Retrieved from http://search.proquest.com.ezp-prod1.hul.harvard.edu/docview/2096642966?accountid=11311

- Jesus Diaz (2018) Dubai mandate that all new buildings be 25% 3D printed by 2025. Fast Company, https://www.fastcompany.com/90228318/dubai-mandates-new-buildings-must-be-25-3d-printed-by-2025

- Corey Clarke (2017) https://3dprintingindustry.com/news/winsun-lease-concrete-3d-printers-saudi-arabia-billion-dollar-constuction-deal-108715/ Accessed on 11 Nov. 2018

- http://www.winsun3d.com/En/Product/prolist/id/1 Accessed on 11 Nov. 2018

- PengWu, JunWang, XiangyuWang (2016) A critical review of the use of 3-D printing in the construction industry, https://www.sciencedirect.com/science/article/pii/S0926580516300681#bb0065

- Mehmet Sakin*, Yusuf Caner Kiroglu (2017) 3D Printing of Buildings: Construction of the Sustainable Houses of the Future by BIM. https://www.sciencedirect.com Energy Procedia 134 (2017) 702–711

- The Construction Productivity Imperative By Sriram Changali, Azam Mohammad, and Mark van Nieuwland. Retrieved from https://www.mckinsey.com/industries/capital-projects-and-infrastructure/our-insights/the-construction-productivity-imperative

- Izabela Hager* , Anna Golonka, Roman Putanowicz (2016) 3D printing of buildings and building components as the future of sustainable construction?

- Least-improved Efficiency eludes the construction industryby Retrieved from: https://www.economist.com/business/2017/08/17/efficiency-eludes-the-construction-industry

- https://www.asme.org/engineering-topics/articles/manufacturing-design/3d-printed-office-the-future

- 3D printed buildings push construction boundaries(2018). . Amman: SyndiGate Media Inc. Retrieved from http://search.proquest.com.ezp-prod1.hul.harvard.edu/docview/2097557693?accountid=11311

- Shanghai-based WinSun 3D Prints 6-Story Apartment Building and an Incredible Home https://3dprint.com/38144/3d-printed-apartment-building/

Zoey —

I thought your article on how Dubai is investing in 3D printed cities was very innovative. I could see how 3D printed cities could be developed given that the additive manufacturing process is advantageous when customization is required. I could also see buildings portrayed as works of art and how the consumer or household could directly impact the design of its future home. However, you posed interesting thoughts on the challenges of 3D printed cities. For instance, I understand the fear that 3D printing may replace the workforce, but I wonder whether 3D printing could actually be beneficial. Given that the appropriate training is provided, I still believe that this process will require an extensive labor force to help design and work with the software to create the exact specifications required. However, I agree on many of the limitations on the types of materials that could be used, the durability issues, and the mass production restrictions that 3D printing faces. Thanks!

Zoey – It is interesting to know that the city of Eidenhoven, Netherlands, has signed a contract with the Dutch company Van Wijnen to provide 3D printed housing solution starting next year. It will be very interesting to follow the progress of the project and its implications on the industry and on the local economy.

Zoey, very interesting read. I wonder, not knowing much about the 3D printing process. Is the technology evolving at a rate that makes such a large upfront investment still worth while? Or are people just “waiting” for newer and better technology to appear? Second, are there any regulatory constraints regarding 3D printing for construction? Given the potential dangers involved, are countries freely allowing these types of construction?

This is a very interesting application of machine learning. I had no idea this was possible today. It does appear that these advancements in additive manufacturing bring a lot of opportunities as well as challenges to an industry very much set in its ways. In the near term, I could very much see a backlash coming from labor unions, safety organizations, and other manufacturers who will be resistant to the changes 3D printing brings. Despite this, you bring up some fantastic advantages to 3D printing. It does sound like a lot of innovation is still required for 3D printing to become common place in building construction.

This was really interesting, and an application of 3D printing that I was unaware of – but it makes sense for all of the reasons you outlined in the article. It’s interesting to step back and look at industries that have been unable to innovate for some time, as you’ve done here. Construction continues to be tedious, time-consuming, costly, and dangerous, and 3D printing seems to solve for many of these. However, as the tech is nascent, I can see why people are reluctant to construct buildings this way, as the potential risks are too high. It’s similar to a recent article I read on applications of 3D in the aerospace industry – the longevity of these materials is unproven and it may take some time for these companies / industries to get comfortable with the implementation of this technology for the long term.