Winning the Beer Game

Water risk management creates interesting opportunities for the world’s largest beer manufacturer, as it anticipates the effects of climate change.

At Anheuser Busch InBev (AB InBev), they have a problem. Water supplies are getting more and more erratic due to climate change. This means a rising cost of water and unanticipated water shortage, which means serious trouble for your Coronas and Budweisers.

In 2015, through their internal assessment process, about 10% of their existing breweries were classified as high-risk in terms of water risk assessment. [1] This means that production output or costs can be substantially disrupted, affecting operating income.

It is no small challenge to manage water. In 2013, near the company’s Taquiña brewery in Bolivia, conflicts broke out between two communities over water access and admin rights for the Taquiña River. AB InBev had to step in and mediate a solution. [2]

However, for all the fans of a nice, cold brew, rest assured, the AB InBev operations team has you covered.

- Diagnosing the problem

The first step they take is available for any company to try out. The World Resources Institute’s (WRI) Aqueduct Tool gives the big picture for any location. (you can try it too)

Once AnBev identifies the key problem locations, they take both the regulatory and the geographical risks into account and perform an analysis using a custom-designed assessment tool, taking various stakeholders (like local communities) into account. [3]

- Starting at the source

90% of the water used in the production process is at the agriculture stage. [4] Worldwide, the company works directly with their suppliers – barley growers – to start addressing the problem. This part of the supply chain represents more than 1 million hectares of cultivated malt barley area. [5]

Previously, some suppliers were individually improving water efficiency through a variety of innovations. But in a classic example of game theory, no one supplier was willing to share information with no guaranteed benefit to them, whilst providing all the benefit to their fellow suppliers.

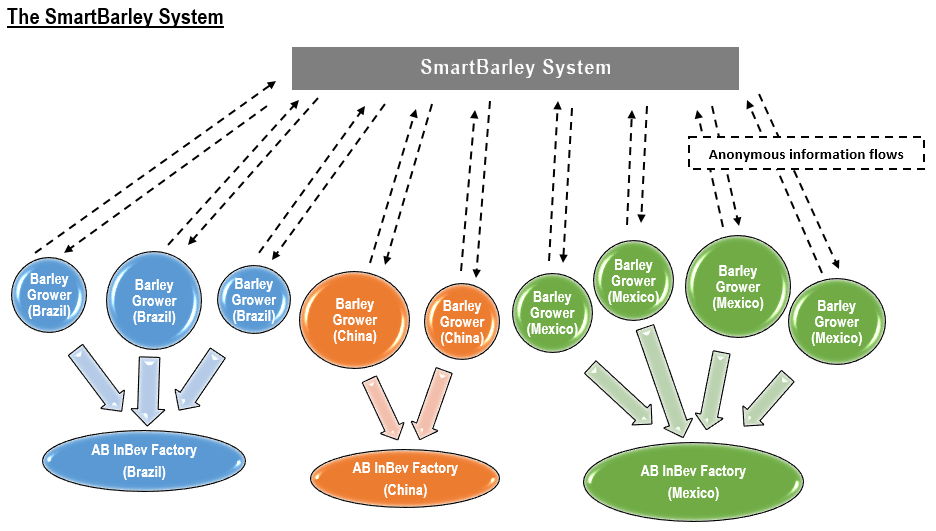

This is where the SmartBarley Benchmarking system comes in. The anonymous platform facilitates information flows between over 1,900 growers in nine countries [6][7], allowing them to optimise their production and water usage through benchmarking. They can use each others data to share best practices, the results of trials and new crop technology.

Similar information sharing projects are being implemented across geographies with partners, including an irrigation scheduler program called AgriMet that links local climate station and farmer data to a platform that helps optimise the use of irrigation water for farms. Results show a 9-23% reduction in water use. [8]

- Widening the funnel for ideas

The company incentivises employees at all stages of production on certain KPIs. And one of these is to provide new ideas for reductions in water usage, thereby reducing their reliance on water for production.

Monetary rewards and recognition are given, driving innovation and widening the funnel for ideas. As a result, employee engagement programs generated dozens of ideas which resulted in a 3% water reduction in 2014 alone. [9]

- Success!

Over the last few years, AnBev has reduced the water needed to produce one barrel of beer from 3.5 barrels to an impressive 3.14 barrels, well ahead of schedule – the goal initially set was 3.2 barrels by 2017. [10] What has it meant? An estimated Savings of nearly 5 million USD in 2014 and more than 12 million USD since 2012. [11]

So what’s next for the team at AB InBev? Greater demand means greater pressure for output, and bigger supply chain challenges. [12]

- No additional steps needed.

This is a company that is adapting extraordinarily well to the challenges of climate change. They have embedded water stewardship into their operations (it is incorporated in key metrics within their ‘Voyager Plant Optimization’ system).

Here’s the takeaway.

In our first month at Harvard Business School we are given a simple premise. First find your customer promise, then design your operations to fit your promise. AnBev’s customer promise is to be the “Best Beer Company Bringing People Together For a Better World” [13] [emphasis author’s own]

This attitude comes through in how they address the problem. By seeing the challenges of water insecurity as an opportunity, that have mobilised their supply chain to perform better. This internalisation of the water concern, is going to allow them to address the challenges to come. The only danger is giving water management too much emphasis – recent press raises concerns about quality trade-offs. [14]

I leave you with an excerpt from a disclosure AnBev submitted to an independent climate change monitoring agency. The agency asked, “Please choose the option(s) below that best explains how water has negatively influenced your business strategy”. The answer from AnBev politely questioned the assumption:

“We have integrated water management strategies throughout our organization and engaged stakeholders locally to improve water management… We view this as a positive influence on our business strategy.” [15]

(Word Count: 790)

References:

[1] Carbon Development Project, “Climate Change 2016 Information Request Anheuser Busch InBev”, https://www.cdp.net/sites/2016/50/22350/Climate%20Change%202016/Pages/DisclosureView.asp Accessed 3rd November 2016

[2] Carbon Development Project, “Water 2015 Information Request Anheuser Busch InBev” https://www.cdp.net/sites/2015/50/22350/Water%202015/Pages/DisclosureView.aspx Accessed 3rd November 2016

[3] Ibid.

[4] Ibid.

[5] SmartBarley. “Home” http://www.smartbarley.com/ Accessed 3rd November 2016

[6] SmartBarley. “Country Profiles” http://www.smartbarley.com/en/Country-Profiles.html

[7] Anheuser-Busch Debuts SmartBarley Benchmarking Program to Generate Higher Yields, Anheuser Busch Press Release. Saint Louis, July 18, 2014

[8] SmartBarley. “Agrimet” http://www.smartbarley.com/en/agrimet.html

[9] Carbon Development Project, “Climate Change 2015 Information Request Anheuser Busch InBev”, https://www.cdp.net/sites/2015/50/22350/Climate%20Change%202015/Pages/DisclosureView.asp Accessed 3rd November 2016

[10] Anheuser-Busch InBev. “Cultivating Water Stewardship: Global Citizenship Report” http://www.ab-inbev.com/content/dam/universaltemplate/abinbev/pdf/sr/global-citizenship-report/cultivatingwaterstewardship.pdf Accessed 3rd November 2016

[11] Carbon Development Project, “Climate Change 2015 Information Request Anheuser Busch InBev”, https://www.cdp.net/sites/2015/50/22350/Climate%20Change%202015/Pages/DisclosureView.asp Accessed 3rd November 2016

[12] Anheuser-Busch InBev NV in Beer, Global Company Profile, Euromonitor,

[13] Hirschstein, N., 2015. Corporate Social Responsibility into the 21st century: Brewing a better future?

[14] Think Progress. “Three ways climate change is going to ruin your beer” https://thinkprogress.org/three-ways-climate-change-is-going-to-ruin-your-beer-bb7bf9977af8#.vu58trd1x Accessed 3rd November 2016

[15] Carbon Development Project, “Water 2015 Information Request Anheuser Busch InBev” https://www.cdp.net/sites/2015/50/22350/Water%202015/Pages/DisclosureView.aspx Accessed 3rd November 2016

It’s really interesting to learn that for AB InBev 90% of the water used in the production process is at the agriculture stage. Since that’s the case, it makes sense that they focused their efforts on working with their farmers and suppliers through the SmartBarley Benchmarking system, which allowed them to reduce the amount of water used to produce one barrel of beer from 3.5 barrels to an impressive 3.14 barrels.

However, I would argue that there are still additional steps needed. Why stop at 3.14 barrels? Just because they beat their internal benchmark of 3.2 barrels ahead of schedule, why not continue to try and improve? Global warming will not stop just because they met their goal. Additionally, the beer production process contributes more to climate change than just through water consumption. For example, there is a brewery in California that built a CO2 recovery system to capture the gas that’s created during fermentation and recycle it back into operations (http://www.npr.org/sections/thesalt/2015/06/24/415538451/survival-of-the-greenest-beer-breweries-adapt-to-a-changing-climate). Also, shipping beer from the factory to the consumer requires a lot of resources, another area AB InBev could focus on.

Awesome post about an awesome company. It is nice to know that ABI is so focused on managing their footprint. I’d also be interested to learn how the company manages the footprint related to the other pieces of their supply chain, particularly packaging. As the industry leader, they have tremendous power to shape consumer preferences and push consumers towards more environmentally-friendly packaging. For instance, while in the US we purchase single-serve beer (i.e packs of cans or bottles), ABI has promoted more environmentally friendly purchasing behavior in Brazil. In Brazil, ABI has pushed the consumer to purchase high volume large multi-serving bottles. Larger bottles designed to be shared among multiple consumers serve to both reduce the company’s cost per liter and carbon footprint. I wonder if the company is trying to use their market power in other regions to push more environmentally-friendly styles of consumption, like large volume bottles for sharing.

Interesting post! It definitely sounds like AnBev is on the right track towards mitigating production issues caused by climate change. As a consumer of beer, though, I have to admit that I’m also worried about the potential quality issues due to climate change that you touched on! Apparently, the concentration of a particular acid in a hop used in some Czech lagers is declining due to climate change and driving lower quality (https://www.newscientist.com/article/mg20327253.400-climate-change-depresses-beer-drinkers). I wonder if this is an issue with other hops varieties as well?

Apek, thanks for sharing. It was very interesting to read how climate change has already created a high risk water environment for about 10% of AB breweries. The simple example of conflict that was provided at one of their breweries is something that many are estimating will continue to occur at an increasing rate. In fact, a recent article published by CNN drew a correlation between the current war in Syria and a drought triggered by climate change (http://www.cnn.com/2015/11/13/world/two-degrees-question-climate-change-and-conflict/). I’m afraid that instances such as this will become the norm unless all parties, to include both the private and public sector, come together to provide meaningful and rapid change.

Thank you for all your comments. A few replies:

@Roanna – With regards to your question on why stop at targetting 3.14, I think there is a limit. I would envision that they run up against the problem of diminishing returns to innovation – where each additional unit of effort has a diminishing effect on water reduction.

@SLHarland & @Roanna – Very interesting points on the additional steps that AB InBev could take and is not taking, like looking at shipping and packaging. Your comments got me thinking about their actual commitment to reducing emissions, and got me rethinking the optimistic tone above! I’m looking at their customer promise a lot more critically now.

I think I would now edit my argument to say that the above example was a huge success because their incentive to reduce water usage from an environmental standpoint, was aligned with the incentive to make their supply chain more reliable and their costs cheaper. Perhaps this is the greater lesson for sustainability planning – to try to align incentives as much as possible.

@Alucido – Interestingly, they are experimenting with different strains. I think this is where GMOs start playing a crucial role

@x96791 This is a key problem. I believe that because exact level of risk due to climate change is difficult to quantify, it is easy for the public sector to not face the issue and resolve it. This maks it difficult to affect ‘meaningful and rapid change’.

Super interesting insights – so glad to see such a large, influential beverage player tackling the issues of climate change head on. However, I have a question about whether there are more sustainability initiatives the company should also be focused on beyond water conservation and efficiency. As mentioned in the article below, the sustainability of hops production is being called into question as climate change takes its toll on fields in areas where hops are typically produced. Does AB InBev use less hops on average than a more “craft beer”-focused brewery? If not, is the company taking any steps to combat this looming agricultural issue going forward?

Additionally, is AB InBev also focused on other portions of its supply chain that affect the environment? For example, other pieces of the production process (including transportation, bottling / packaging, and refrigeration) also contribute to the carbon footprint. Given its size and scale, has the company considered trying to push some of their eco-friendly principles on to their partners – for example, by introducing certain minimum sustainability standards for organizations that it does business with?

http://www.ecowatch.com/climate-change-poses-threat-to-key-ingredient-in-beer-noaa-warns-1882168560.html

Great post. It sounds like AB InBev has identified the biggest affect of their operations on the climate and taken the steps to address it. I would be curious to see more details on how difficult their goal of 3.2 barrels water / barrel of beer was to achieve. Since they easily achieved this goal, are they continue to try to reduce the amount of water used?

Furthermore, I am interested to see if there are any other steps that InBev is taking to address climate change besides water usage. A few possibilities that come to mind are reducing GHG emissions arising from producing, refrigerating, packaging, and delivering. A company this size would likely have a significant impact on the environment at each of these stages, and stands to gain significantly if it can develop a plan to improve them.

Great write up! Many cool insights that I did not know or think about that are impacting brewers. From a high-level view, this reminds me of Starbucks and how a big part of the impact on climate change happens in the step of the supply that is not directly controlled by them. In Starbuck’s case it is in the coffee farmers (their suppliers), in AB’s it is in the barley growers. This provides a challenge in that both AB is not in direct control of what happens in other stages of the supply chain and also that water is a key ingredient in beer, that is not likely to go away. So I believe that it is great that they are directly engaging their suppliers to assist them in finding ways to be more water efficient. Furthermore, their mechanism of fostering an environment of best-practice sharing, using this common practices platform is very innovative and something to takeaway for other industries in hopes of improving their supply chain; very admirable.