Will you marry me (if I ask with a 3D-printed ring)?

Additive manufacturing in jewelry has enabled rapid prototyping of customer-specific designs, improved the speed and accuracy of creating wax molds, and is beginning to disrupt traditional production methods with the direct printing of finished products using precious metal powders.

Traditional Jewelry Production

Traditional handmade jewelry begins with an artist carving wax into a model that takes the shape of the future jewelry item. The wax is then surrounded by plaster (“casted”) and heated. The heat melts the wax, which is extracted from the hardened plaster, leaving behind a mold in the desired jewelry shape. The mold, which can be used many times, is filled with molten precious metals to create pieces of jewelry. [1]

Creating these wax models by hand is time-consuming, labor-intensive, and error-prone. Over the past decade, digital design and 3D printing of wax models has enabled jewelers to produce more intricate molds, more accurately, in shorter lead times – a cost-effective method for many-unit jewelry production. [2]

Breaking the Mold

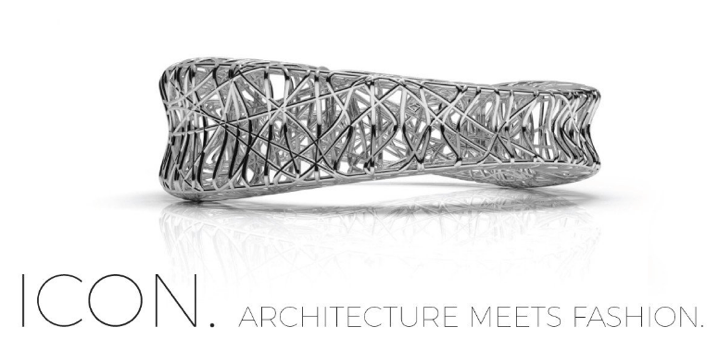

As the process for 3D printing metal has improved, technologically-advanced jewelry producers have started directly printing custom metal pieces. Toronto-based jewelry manufacturer Daniel Christian Tang (DCT) has started to print end products, which can take hundreds of hours to design but less than an hour to print a copy of. [3] 3D printing of most metal has been highly challenging technically: the high melting points of precious metals make traditional it difficult to print from sheets of metal using Laser-Induced Forward Transfer. [4] Material innovations have made metal printing possible by printing and heating metal powder to create a solid.

Image Source: https://www.danielchristiantang.com/

The concept for DCT was predicated on the application of 3D printing to the jewelry world. Cofounders Mario Christian Lavorato and Heng Tang met while pursuing a Master’s in Architecture. The duo realized they could turn their digital architectural prototypes into wearable pieces of art. [5] As printable powdered metal becomes more accessible financially, companies like DCT will be able to print finished goods at attractive margins. DCT already boasts a 40% average margin, compared to the jewelry retail industry’s bleak average of 5%. [3]

Other jewelry manufacturers are leveraging 3D printing for rapid prototyping of custom designs for consumers. After discussing desired specifications and designing them digitally, jewelry makers will print a wax model for the customer to review in under an hour. This rapid prototyping has greatly reduced the time and cost required to respond to customer design requests, and the potential speed to market is attracting new designers. [6]

Source: https://formlabs.com

Scaling a 3D-Printed Design Operation

3D printed jewelry is estimated to reach $900m in market revenues by 2026, a small percentage of the global jewelry market (estimated over $200bn in revenue by 2020). [7] As materials and machinery costs continue to fall in additive manufacturing, more artisan jewelry makers and tradesmen will invest in 3D printing tools to create molds and print individual pieces of jewelry. DCT has opened a factory in Hong Kong in an attempt to produce their intricate, high-fashion printed jewelry at scale.

Further enhancements to CAD software and user interfaces will also drive growth in 3D printed jewelry. Designers like John Brevard believe the future of his business depends on the customer-designer relationship. Brevard launched a digital customization platform called Thoscene in which customers can input personal astrological data to create a custom-designed piece of jewelry. [8] The flexibility in small production 3D printing allows jewelry manufacturers to bring customers into the product design and development process much earlier.

Source: http://www.thoscene.com/

I believe commercialization efforts need to pick up for 3D printing jewelry to continue to grow. In the ultra-high-end jewelry markets, customers won’t be involved in the product development process, as they are paying designers to create works of art that will be unique and fashionable. In the low end, fast-fashion market, jewelry needs to be mass produced, also precluding the customer from giving input into design. In these cases, the advantage of rapid prototyping is lost. The middle market for highly-customized printed jewelry seems to be more niche than scientists, bullish on the technology, make it seem. I think partnerships with established jewelry retailers may be an attractive path to market for new entrants to leverage the technology while limiting capital for marketing spend.

Room for Debate

While promising, the market for 3D printed jewelry is still nascent. Will the technology and economics of printing precious metals ever eclipse wax-casted molding? Will consumers accept a piece of “art” that has been printed? And if we allow customers so much influence over product design, will that be the end of innovation in art and fashion?

(764 words)

- “Making Jewelery.” Jewellery World, Sept. 2010, pp. 32–33. EBSCOhost, ezp-prod1.hul.harvard.edu/login?url=http://search.ebscohost.com/login.aspx?direct=true&db=bth&AN=53496166&site=bsi-live&scope=site.

- “Process Advances Bring Metal 3D Printing into the Mainstream.” ECN, Oct. 2017, pp. 12-14. EBSCOhost, http://web.b.ebscohost.com.ezp-prod1.hul.harvard.edu/ehost/pdfviewer/pdfviewer?vid=0&sid=60f1924c-97c0-4b6a-8e59-c24403b64893%40sessionmgr101

- “Rare Jewelry That Isn’t So Rare Anymore.” Bloomberg Businessweek, March 2017, pp. 36-37. EBSCOhost, http://web.b.ebscohost.com.ezp-prod1.hul.harvard.edu/ehost/pdfviewer/pdfviewer?vid=0&sid=bfc2dc17-578d-4fc5-8868-be5081e94c68%40pdc-v-sessmgr02

- “Toward 3D Printing of Pure Metals by Laser‐Induced Forward Transfer.” Advanced Materials, June 2015. Accessed via Wiley, https://onlinelibrary.wiley.com/doi/abs/10.1002/adma.201501058

- “Canadian label Daniel Christian Tang transforms 3D prints into statement jewelry.” Calgary Herald, March 2016. Accessed online, http://www.calgaryherald.com/life/fashion-beauty/canadian+label+daniel+christian+tang+transforms/11784128/story.html

- “They Facilitate 3D Printing.” CE Noticias Financieras, October 2018. Accessed via Factavia, https://global-factiva-com.prd1.ezproxy-prod.hbs.edu/redir/default.aspx?P=sa&an=NFINCE0020181002eea2002hh&cat=a&ep=ASE

- “SmarTech Publishing: Annual Revenues from Additive Manufacturing in Jewelry Expected to Top $900 Million in 2026.” Travel & Leisure Close – Up, Feb. 2017. Accessed via ProQuest, http://search.proquest.com.ezp-prod1.hul.harvard.edu/docview/1871488697?accountid=11311.

- “Jewelry Makers Sieze on 3D Printing’s Speed and Ease.” Financial Times, March 2016. https://www.ft.com/content/3f870cbe-c4e5-11e5-808f-8231cd71622e

Jewelry is often viewed as an emotional and sentimental purchase, including the purchase of an engagement ring, wedding band, graduation gift, etc. High-end jewelry retailers have focused advertising on the purchase as an experience, justifying the price by highlighting hand-crafted detailing and the use of rare and luxurious materials. Even in the low and medium-end jewelry markets, consumers are still wooed by the traditional allure of artisan products that are handcrafted. As you mention, I think that companies seeking to employee 3D printing technologies to jewelry development will need to focus their attention on changing consumer perceptions of what it means to buy jewelry. One potential avenue is target individual who purchase and wear jewelry as a form of self-expression highlighting the ability of 3D printing to create more complex and unique designs.

One of the problems with the traditional wax-casted modelling is the high degree of wastage and redundancy that occurs from hand or machine fitting luxury metals such as gold, silver and platinum. The ability to reduce this wastage through the accuracy of 3D printing would remove this as one of the major cost components in jewelry manufacturing. If this could be reliably achieved at scale, then economics of 3D printing jewelry would become far more attractive. Where I see this technology becoming most disruptive in the jewelry industry is in changing the way consumers buy and shop for jewelry. Jewelry is still very much a ‘brick and mortar’ business with customers frequenting jewelry shops to inspect the product prior to purchase. Allowing customers the ability to ‘self-create’ possibility opens up the ability for retailers to shift to a more digitally distributed model.

Great article that definitely inspired me to check out some 3D printed jewelry myself!

In my opinion, the question of whether 3D printing precious metal molds will ever completely replace eclipse wax-casted molding is a purely economical one, as the technical aspects already seem to outweigh the wax technique. For fully 3D printed jewelries, the situation is more arbitrary. Especially for higher priced jewelry, I can imagine there being a large demand for “hand-crafted”, “traditional”/”original” jewelry as you see in other segments of the luxury goods market.

Great to see an article about additive manufacturing and its applications in jewellery making.

One of the benefits in addition to cost and time reductions is that 3D printing allows designers to produce intricate, organic shapes that are impossible to produce using traditional wax molds. Digital models add to the freedom for clients to customise each piece according to their own needs. I think the value proposition of additive manufacturing is not replacing the traditional production method but improving the prototyping process.

To your last question, the romantic notions attached to the craft of jewellery making will be a bigger barrier of adoption for luxury brands like Tiffany. If the technology improves to the point which custom jewellery can be offered at a fraction of the cost of traditional pieces, there is definitely business opportunities for startup to capture the market.

Anecdotally, I think my wife would have loved this when we got engaged. She, and I assume many other women, had a general design in mind and scoured jewelry shops for hours looking for exactly the “type” she wanted. With this technology, she could’ve told me generalities of what she wanted in terms of design, and I could’ve told a jeweler that design and my willingness-to-pay so that we could’ve gotten a near-perfect ring for the money.

I agree that mid-tier jewelers would be most interested, but I think even high-end stores may get on-board since a customer could ask for general characteristics of a ring and then give a designer an artistic license to craft something beautiful as long as it met the customer’s general criteria.

Interesting read! Engagement ring purchasing is such an emotional experience due to the financial size of purchase and meaning behind the purchase. I completely agree with your perspective that the current market for 3D printing is small given these characteristics. That said, if a 3D printing company is able to show consumers lower costs and increased customization, while also receiving no social stigma, this innovation could quickly take market share. It will be interesting to see how manufacturers such as DCT try to overcome these market dynamics.

Very interesting application of 3D printing. I agree with your assessment that the greatest potential exists in the middle of the market, though I think it could go two ways. The iterative possibilities of designing custom jewelry might open up the higher end of the middle of the market given the higher level of “service.” Alternatively, if jewelry makers seek a value advantage, perhaps they will leverage the technology and pass on the cost savings to the consumer and make upper-middle market jewelry more accessible at greater scale.

Very interesting article. I agree with your and previous post opinions that the greatest potential seems to be in the middle market. I also think this particularly applies to engagement rings because of the desire to make it unique and personalized. 3D printing makes production faster, but it could still take several hours (or days or months) to do the computer design to be printed. This would translate to a higher price, which I think people would be more willing to pay for an engagement ring than every-day use jewelry. I think companies would have to find a balance between offering the customization that comes with 3D printing while limiting design time to make each sell profitable.

Awesome article! I do agree that the cost for jewelers to adopt 3-D printing may not render the appropriate financial gain. One of the biggest benefits in the jewelry industry is the ability to quickly change design without incurring a large cost associated with the change. Particularly in a service industry, one that typically observes a high average purchase cost, I see the flexibility in design that 3-D printing allows for to be extremely beneficial. It is easy to transfer the 3-D file as well and can facilitate customer input or design edits.

You ask if consumers will accept a piece of “art” that has been printed. I think consumers will have almost no problem accepting printed jewelry – practically, it’s not very different from traditional wax-casted jewelry. I think a much bigger barrier for consumers will be switching from “natural” jewels to synthetic stones. The romance and story behind where the gem came from will still be important…but I think how the sausage is made, once the pig has been slaughtered (so to speak), will be less important for consumers

As I read your article, the same question of whether consumers will accept 3D printed jewelry as “art” came to mind and I think this question can be applied widely to the retail industry as 3D printing takes a larger role. As computers adopt the ability to design art without human intervention, will there be any need for an artist in this process at all? I think there will always be a role for human artists for a portion of the market, but it may become a very small role and will likely reside at the top of the market where discretionary income can afford an individual the ability to be less efficient with their capital allocation.

I wonder to what extent cheaper manufacturing of rings (in terms of labor costs, etc.) will cause consumers to demand nicer/larger jewels (making total cost of the ring to the consumer equal). Increasing the demand for precious stones could have impacts far beyond the retail industry.

To add to the debate around consumer preferences, I think 3D-printed jewelry fits nicely into the millenial desire to have greater customization and a greater transparency around sourcing. Within the wedding ring industry in particular, customization is key. Everyone wants something that is completely unique, both because there is a trend of diverging preferences, and also because the wedding ring is such an intensely personal and meaningful item. Knowing that a ring was custom-made (and no other exactly like it exists in the world) should lead a potential pricing premium opportunity. If costs do come down, that would lead to a very attractive margin. There may also be a way to re-create a special customer experience that appears to be so critical in the wedding ring industry by having an intimate setting for talking through the design and creating a special process for receiving the wedding ring.

I personally think consumers will have no problem buying 3D printed rings. As the technology evolves, these rings will be indistinguishable from traditionally manufactured ones. The interesting conversation here is the future of growing synthetic diamonds to adorn these printed rings. Recently, Lockheed Martin filed a patent for a 3D printer for synthetic diamond [1]. Although this will surely be used for industrial purposes, as the synthetic diamond space grows I’m interested in the consumer reaction to these products. Would you want to buy a lab-grown diamond for your fiance? Would you want to receive a 3D printed diamond on your engagement ring? I personally believe that the marketing power of the big diamond companies will prevent these “fake diamonds” from gaining too much momentum but I sincerely hope that societal pressure moves the industry more towards that space.

1. https://3dprint.com/146562/diamond-3d-printer-lockheed/

Really interesting article! To your second question, although I think 3D printing could be extremely useful in the jewelry industry I am nervous about its adoption for production, even in mid-tier category. For jewelry and other luxury goods, the perception of the jewelry is sometimes more important than its actual aesthetics, and having something that’s “handmade” will always be valuable, even with flaws. For example with nice dress shoes, having imperfections is a sign of quality because it means they were not machine made. I’m just not sure machine printed jewelry would ever be able to overcome this stigma at the high end, and at the low end it probably doesn’t make economic production sense. That being said, I do think it can replace wax molds. The wax process sounds unnecessarily complicated and it sounds like 3D printing can provide a more capable, efficient process while still allowing for a personalized professional design.

I think a risk to the success of 3D printing in the jewelry market is the inherent cheapness of the product. Jewelry has high significance to the owner and buyer, and carries an undeniable emotional element. It is primarily a gift driven business, and often the price tag or the “bigger the ring” is extremely important in the buying decision and signals how much you care about the person you are buying for. I think there is a place for 3D printing in the jewelry market, but it will be for lower end product.

I agree with your comment that additive manufacturing will allow greater customization of jewelry, especially when considering that both the mold and the jewelry itself can be 3D printed. As we think about greater customization and the printing of one layer of material on top of another, I wonder if we can customize not only the design of jewelry but also the way we use precious materials to create jewelry. For example, I can envision a piece of jewelry that is made of multiple precious metals that don’t intermix. Perhaps additive manufacturing will allow for more precise designs where we can also personalize how we use precious metals within jewelry.

Really interesting article. I agree that this technology has a lot of potential in the middle a segments for the rapid-prototyping of custom-made rings. However, I am skeptical of its success in the higher end segment. Luxury jewelry is usually an emotional purchase that people are willing to pay and high premium for because of the craftsmanship/uniqueness. It is likely that consumers will regard this as an inferior product and t will be incredibly difficult to change customers’ perception and buying patterns.