United States Navy: Digitizing Logistics to Maintain Maritime Superiority

USN forces are increasingly being used in critical global situations while simultaneously operating under the stress of strict Department of Defense (DoD) budgets and growing enemy technological capability. Digitization of the supply chain is imperative for the USN to maintain the sustainability, agility, and responsiveness to support its far-reaching operations in a fast-paced, potentially dangerous environment. But will digitizing the USN's supply chain information create even more vulnerabilities?

Charged with maintaining sustained combat readiness in support of national interests, the United States Navy’s (USN) task of providing logistical support to its 278 battle force ships, 101 attack submarines, 3,700 aircraft, and 324,460 personnel deployed around the globe is no easy feat. [1] Moreover, these USN forces are increasingly being used in critical global situations while simultaneously operating under the stress of strict Department of Defense (DoD) budgets and growing enemy technological capability. Digitization of the supply chain is imperative for the USN to maintain the sustainability, agility, and responsiveness to support its far-reaching operations in a fast-paced, potentially dangerous environment.

To put the logistical demand in perspective, one aircraft carrier can hold around three million gallons of jet fuel for its 50+ aircraft. If all 50+ aircraft were to fly operations simultaneously, these three million gallons of fuel would only last for two and a half days. Furthermore, an aircraft carrier, comparable in size to a small city, holds 5,000+ personnel who consume approximately 18,000 meals a day, costing the USN around $65k a day in food supplies. Additionally, aircraft carriers demand constant access to weapons and maintenance parts and, of the 278 battle ships in the USN fleet, 11 are operational aircraft carriers. [4]

The timely replenishment of food, weapons, fuel and supplies to USN ships is critical not just to the lives of thousands of Americans and its allies, but also to national security. Nevertheless, USN forces currently utilize multiple dated, inefficient logistics software systems that make logistics planning stove-piped, vulnerable to cyber attacks, rigid, and difficult to audit. For example, the USN utilizes software referred to as RSupply for the logistical and financial management of spare parts and general inventory, but utilizes different, more specialized systems to oversee the replenishment of weapons, hazardous materials, food, and medical supplies. These multiple logistics systems are used by separate communities with different financial lines of accounting within the USN. However, there is currently no way for these different systems to communicate, resulting in silos of data that requires time-consuming, wasteful resources to aggregate information simply for the USN to maintain a current logistical picture. [5]

Not only does the current system create financial and operational inefficiencies, but it also presents the USN with an inability to adequately predict future supply needs and plan for wartime or weather-related contingencies. When planning for a wartime scenario, for example, a strategic planner must take into account where to place key operational assets and how to streamline resupply in the event that central logistical hubs are no longer available due to an attack. Without having a centralized database for logistical information, decision-makers will be unable to sufficiently adapt and respond to dynamically changing environments. Additionally, the USN is increasingly focused on how to operate in a communications-denied environment due to the risk of enemy attacks on communication systems. In a situation where a ship loses communication with station, the centralized logistics database allows headquarters to better estimate what this ship might need based on previous usage rates and on what similar ships are utilizing. [7]

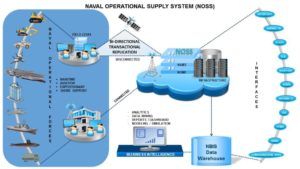

In the short to medium term, the USN is working with the Naval Warfare Systems Command (SPAWAR) to develop the Naval Operational Supply System (NOSS) to replace and consolidate 15 legacy logistics applications. NOSS will allow for forecasting, procurement, and accountability of supplies across all supplies and communities, thus finally enabling enterprise wide automation of supply. Moreover, NOSS will allow the USN to aggregate and analyze supply data using a business intelligence framework. [6] Ultimately, NOSS allows the USN to be better poised to respond to peacetime and wartime logistical issues, while increasing cost and resource savings. SPAWAR is expected to complete NOSS by 2021. While NOSS is being built, USN Supply Corps personnel will work with the fleet to ensure current logistics procedures are updated in preparation for the installation of NOSS. [5]

Enhanced digitization and aggregation of supply data through NOSS will increase USN supply chain agility, responsiveness, and cost-effectiveness in wartime and peacetime. However, in an environment of increased enemy cyber threats, will the single source system and aggregation of data leave the USN even more vulnerable to enemy cyber attacks? Are there other tradeoffs that the USN should consider as it works to implement a new supply chain digitization system?

[1] Status of the United States Navy

[2] Defense Logistics Agency: Strategic Plan 2015-2022

[3] Sea Water to Jet Fuel

[4] Aboard the USS George HW Bush: How to cook dinner for 5,000

[5] The Future of Navy Log IT: Naval Operational Supply System

[6] The SPAWAR List 2017

[7] Push Logistics in a Communications Degraded/Communications Denied Environment

This was really interesting Ally!

Assuming these aircraft carriers aren’t always near land or other supply ships, I am curious what the lead time is and potential variation to resupply some of the different items. For example, does the weight and volume of fuel mean that resupplying the aircraft carrier with fuel takes longer because it has to come from another ship or is the demand for fuel more predictable so the planning is easier? Would smaller more specialized orders of maintenance parts be able to be flown in?

At first, I was thinking that you could have automatic sensors to track consumption of the various items (at least those easy to measure) so the information is constantly getting “pulled” vs having to get “pushed” into the system by personnel – but, that magnifies the potential risk of cyber attacks.

What a fascinating article! It was great to learn about the Navy from this perspective which is otherwise rarely brought up.

In regards to your questions I can see how having one system rather than 15 different systems increases the risk of a cyber attack, but I would argue that the benefits outlined in your article far outweigh the risks associated. Moreover, I would argue that if someone manages to get into one of the systems, it would not be that hard to get into another one or the attacker would pick the one with most sensitive information (i.e. replenishment of weapons), but I might be wrong (you should probably ask Zeya).

I am not entirely surprised by the fact that the current digital supply chain for the US Navy is ineffective. The government has to balance the tradeoff between control and innovation, while minimizing disruption to the current processes. While I am not concerned about the consolidation of the systems from a cyberattack perspective – I think the innovation likely helps create a more robust system – my major concern was that the USN is working with the Naval Warfare Systems Command to develop the system, rather than partnering with a private corporation. While security clearances would be an issue in a public/private partnership, the Navy could likely get a more state of the art, secure system. There are companies that specialize in developing large, secure ERP (enterprise resource planning) systems that I can’t help but think would be more prepared to take on the challenges than a government organization. A partnership like this could also help reduce the timeline for the system’s launch and provide assurance that the technology has been effective in the past (both when launched and when ‘attacked’).