The Sustainability Paradox: How Vale S.A. is Operating in the Heart of the Amazon Rainforest the New World´s Largest Iron Ore Mine

Is it possible to sustainably operate a large-scale iron ore exploitation project without causing significant environmental disturbs in one of the most sensitive biomes on Earth? Vale claims to have found the solution in its new S11D complex with the application of cutting-edge technologies that are considered generations ahead of common practices in the mining industry.

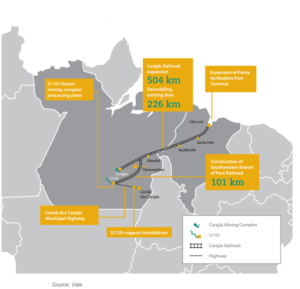

When Vale recently cut the ribbon on the S11D complex inauguration it expected to create a landmark in the mining industry where high productivity and environmental intelligence are strictly associated. Located in the heart of the Amazon Jungle, in the Brazilian state of Pará, the controversial USD 19,67 billion project not only has an impressive cost but also massive proportions. In total, the company built 63 miles of new railroads, upgraded another 315 miles from single to double track, retrofitted an entire port terminal and invested in the construction of a brand-new processing plant [1]. The attempt was to establish a completely verticalized and sustainable supply chain in the middle of the forest where 90 million tons of iron ore would be extracted, processed and transported every year by Vale [2]. Given the location´s biodiversity and high susceptibility to climatic changes, the stakes were high and the greenfield project had to comply with the industry´s most rigorous environmental standards to receive the operational legal licenses.

Sustainable Solutions Aimed to Address Environmental Challenges

Deforestation reduction and the rationing of water and energy are key challenges today faced by most mining companies during the conceptual phase of their projects. At the S11D complex, the open mine pit is located within the boundaries of a National Forest Reserve and the area hosts the largest plant species biodiversity on Earth. In this sense, the implementation of technologies focused on the reduction of the deforested area and greenhouse gas emissions were of paramount importance for the mitigation of environmental impacts. Vale has heavily relied on automation to address most of these issues. The processing plant was physically separated from the mine and installed in an area outside the national reserve, minimizing the deforestation footprint and preserving over 2.5 million acres of forest. A 6-mile truckless conveyor belt system was developed to carry the ore from the pit face to the plant, eliminating the use of trucks. This innovative solution was implemented in an unprecedented scale in the industry, which allowed a 70% reduction in fuel consumption and 50% in carbon emissions compared to a usual operation [1] [3].

https://www.youtube.com/watch?v=dlFpv-oCzIg

The standard iron ore processing techniques also utilize high volumes of water to separate the ore from the gangue, generating a contaminated byproduct that must be stored in tailing dams. These structures are risky environmental liabilities that may present unparalleled consequences in case they collapse. In November 2015, Brazil witnessed the worst environmental disaster of its history when Samarco´s1 tailing dam burst, releasing millions of tons of toxic mud into a river called “Rio Doce”. A few days later the toxic mudflow reached the Atlantic Ocean, and its impact on the regional biome and local climate are still unclear. For the S11D project Vale has developed in partnership with its suppliers a breakthrough system that is capable of dry processing high moisture content iron ore without the need of using additional water. As a result, no tailing dam had to be constructed and the energy-efficient technology reduced the water usage by 93% and electricity consumption by 18k MWh [1] [4] [5].

https://www.youtube.com/watch?v=T9_0DWpUcOE

As a major player on its sector, Vale has the capability not only to extend these technologies to other projects, but also to leverage its efforts in favor of environmental friendly solutions as standard practices on the industry. The company should also develop a program to monitor pollution and plant suppression on the area, in order to minimize the impacts caused by the project in the surrounding biome and allowing in the future the use of these same plants in the restoration of the site.

Ongoing Concerns

Even though the innovations adopted by Vale at the S11D complex have the capability to disrupt the industry and mitigate the negative environmental impact associated with most mining operations, there are still ongoing concerns related to the real sustainability of these projects. Is it worth it to risk the balance of one of the world´s richest biomes in exchange for a 30-year iron ore exploitation project? The region where Vale has concentrated its operations at the Amazon Jungle will likely continue to raise controversy amongst industry experts. The paradox of having an extremely high iron content soil will constantly face the fact that it is also a region of unparalleled biodiversity. Technology might be able to mitigate several concerns but will it ever be able to completely resolve the environmental effects caused by the mining activities and its possible consequences on the local climate change?

(Word Count: 745)

1 Samarco S.A. is a Brazilian mining company controlled by BHP Billiton and Vale S.A

[1] “Vale – S11D – O maior projeto de mineração do mundo..” (2017). Vale.com, <http://www.vale.com/hotsite/PT/Paginas/Home.aspx> (Nov. 15, 2017).

[2] Lu, L. (2015). Iron ore. Woodhead Publishing is an imprint of Elsevier, Cambridge, UK, 261.

[3] Topf, A. (2017). “Vale opens largest iron ore mine in its history | MINING.com”. MINING.com, <http://www.mining.com/vale-opens-largest-iron-ore-mine-history/> (Nov. 15, 2017).

[4] “The Mariana mining disaster – A journey through Brazil’s worst environmental disater.” (2017). FRANCE 24, <http://webdoc.france24.com/brazil-dam-mining-disaster-mariana/> (Nov. 15, 2017).

[5] “Vale opens ‘world’s largest’ mining project.” (2017). Financial Times, <https://www.ft.com/content/aebec85c-c547-11e6-8f29-9445cac8966f> (Nov. 15, 2017).

This is perhaps one of my main concerns in today’s world Thiago, the long-term disruptive effect that human exploitation can cause on biodiverse habitats such as the one that lives in the lung of the world: The Amazon jungle. Few years ago, The Smithsonian reported that the mining industry has had an incredible disrupting effect on ecosystems around the globe and that one way to reduce it was to ask companies that source those precious materials such as Tiffany & Co. to stop sourcing what it was related as “dirty” gold, which could also apply for other minerals mined around the world (https://goo.gl/U9MU8G).

I am delighted to see that you chose a vital topic in a project that I am sure will become a historical reference for the world, either for the transformational change of an industry or for a pitfall that will have unmeasurable ecological consequences, which I truly hope is the former.

It is unavoidable that as the population increases and with it a large need of resources, humans continue to search for untapped areas where precious metals can be extracted. The key issue is how governments in developing countries can protect national resources that will eventually affect the current or future of climate change around the globe. It is very difficult to estimate the future environmental cost of a project such as the S11D conducted by Vale because even if the new technology can reduce energy and water consumption, it is uncertain the short-term and long-term impact in a complex biological environment with so many entangled variables and with a not entirely understood Amazon’s flora and fauna.

Many times, these projects are accepted because lobbying and political pressures on local officials by multinational corporations, and it is imperative to resist the temptation of making decisions solely based on the short-term financial rewards without contemplating potential ecological disasters so we can ensure we leave this planet in a better shape we found it for our children and the generations to come.

Lastly, in a similar way, foreign companies have come to Colombia to create one of the largest gold mining explorations in the middle of a natural reserve. They continuously lobbied the government until they reached the permits to continue the explorations and extraction against several academic experts and international organizations claiming that those efforts will compromise one of Colombia’s most important water supply (https://goo.gl/k24HF6).

I’m very impressed with the 6 miles conveyor belt they built, especially when its job is to move iron ore. I see the argument that this effort would save petrol fuel and CO2, however, I wonder what’s the cost of electricity and initial investment. From an energy perspective, even electricity comes with pollution. It’s just that instead of having visible emission at the site, pollution of electricity generation comes at the generating site. A vast majority of electricity still comes from burning coal. So, there are more calculations need to be done to unveil if this project is really environmental impact positive.

I appreciate that these innovations are happening and certainly agree that the power, emissions, and water benefits are impressive, but there is definitely still the issue of high consumption of the earth’s resources. This is a great bandaid solution to sustainably extract iron ore, but it’d be great to see Vale working to reduce consumption overall in order to reduce the need to plunder the rainforest.

Great article Thiago. Although I agree that companies are continuously improving their processes and strategies in order to have a lower impact on the climate and the population, I wonder if this is their end goal or a simple consequence of more efficient technology.

I think that as long as there is demand for the products or commodities that Vale produces, they will have to supply it or else someone else will. This is why the negative effects on the planet at a local or regional level will continue to occur unless the end product is modified to require less or no raw materials that need harsh harvesting. This, however, plays against Vale since it would theoretically go out of business. This is a nice article to look at conflict of interest from a broader point of view.