The Bitter Truth for Beer

How much are you willing to pay for a cold draft after a long day’s work?

Record high global temperatures and shortages of key ingredients have created an uncertain future for the world’s most consumed alcoholic beverage – rising prices might just be the start.

The Impact of a Changing Climate on the Beer Industry and MillerCoors

Climate change matters to breweries for two principal reasons. First, beer relies heavily on agriculture –its primary ingredients are hops, barley, and yeast – and a changing climate significantly impacts the ability to produce these crops to consistent quality and quantities. Second, the beer production process is highly energy intensive and ranks as one of the world’s heaviest users of water. [1]

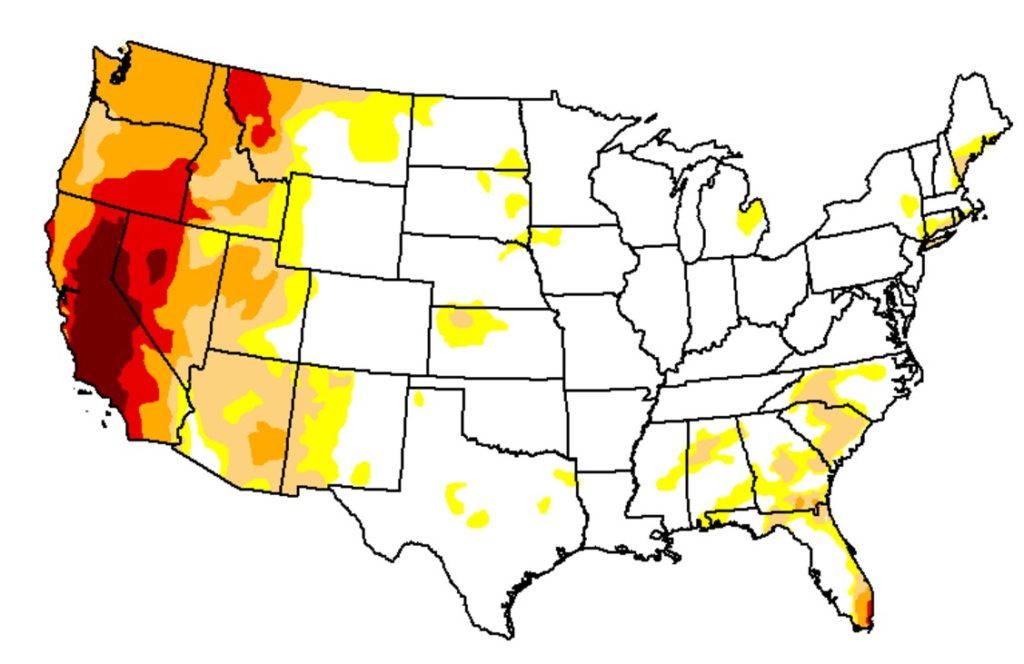

Hops, grown primarily in the American Northwest, provides the bitterness and aroma that gives different beers such unique flavors. [2] Over the past several years, weather in the Northwest has been unusually warm, with both 2015 and 2016 reporting moderate to severe drought during the hops harvest season (Figure 1). Hot temperatures disrupt hops yields and require heavy reliance on irrigation systems, straining water supplies. Cultivation of hops and barley are typically responsible for more than 90% of the water used in the beer production process. [3]

As the largest American-owned beer producer, MillerCoors is both a victim of and a contributor to the significant impacts of climate change. Facing increasing pressures from the public, rising energy and production costs, and intensifying regulation, MillerCoors and other breweries around the world have no choice but to evolve.

Figure 1: Drought afflicted areas of the United States, July 2015. [4]

MillerCoors has Taken Important Steps to Reduce its Impact on Climate Change

MillerCoors, recently acquired by the world’s third largest brewer, Molson Coors, manages some of the best-known brands in beer. The organization has launched several important initiatives to reduce its impact on climate change, taking a three-pronged approach in what it refers to as its Great Environment program.

- Reducing water consumption and restoring water in stressed regions. In 2015, MillerCoors achieved a water to beer ratio of 3.29 to 1, beyond its goal of 3.5 to 1 and on track to achieve an ambitious target of 3 to 1 by 2020. Additionally, the organization will soon be restoring fresh water equal to the amount of final product volume at breweries in water-stressed areas, including California, Texas, and Colorado. [5] Lastly, MillerCoors is working with their growers throughout the U.S. to limit water waste. It recently launched its Grower Portal, a digital platform enabling growers to share data and best practices regarding water usage. [6]

- Reducing carbon footprint across the supply chain. MillerCoors assessed its entire supply chain and plans to reduce its carbon footprint by 25% (2010 baseline) by 2020. By 2015, the firm had already reduced its footprint by 18%, thanks to efficiencies in brewing, packaging, and transportation.

- Eliminating waste at major manufacturing facilities. By 2020, MillerCoors plans to have landfill-free operations across all manufacturing facilities with more than 75 employees. By 2015, it had already achieved this at its 8 major breweries across the country. [7]

Click here to learn more about how MillerCoors’ sustainability efforts. [8]

There’s More to be Done

While MillerCoors deserves commendation for its sustainability efforts to date, there is still much more the firm must do to reduce its climate impact. To start, the company can look for inspiration to smaller, craft breweries, many of which have sustainability deeply rooted in their cultures and operations.

- New Belgium Brewery has created a sustainability SWAT team – comprised of engineers, production managers, and environmentalists – to identify innovative solutions to reduce natural resource consumption. They recently launched an internal electricity tax, charging the firm for all energy purchased and earmarking the funds to invest in energy efficiency projects. [9] More than 15% of the firm’s energy needs is produced onsite through solar and recycled methane. [10]

- Sierra Nevada Brewing Company, the second largest craft brewer in the U.S., has one of the largest privately-owned solar farms in the country, leveraging over 10,000 panels to produce 20% of the company’s energy. Another 30% of its power is sourced from on-site hydrogen fuel cells. [11] Sierra Nevada’s efforts were rewarded in 2010 by the United States Environmental Protection Agency when it was named “Green Business of the Year.” [12]

- Odell Brewing produces 100% of its electricity through renewable resources, 5% of which is from onsite solar panels. The company also uses insulated brew vessels to increase energy efficiency and recapture steam for heating purposes throughout the brewing process. [13]

In addition to incorporating initiatives like these into its operations, MillerCoors should consider taking a more active presence in the climate change conversation. For example, the company could consider signing the Ceres Brewery Climate Declaration (Figure 2). Doing so would publicly demonstrate its commitment to wholly addressing climate change and would set a firm example for other major brewers around the world.

Figure 2: Ceres Brewery Climate Declaration. [14]

(783 words)

[1] Abass A. Olajire, “The Brewing Industry and Environmental Challenges,” Journal of Cleaner Production (2012); 1.

[2] Caitlyn Kennedy, “Climate & Beer,” Climate.gov, January 13, 2016, https://www.climate.gov/news-features/climate-and/climate-beer, accessed November 2016.

[3] Gina Roos, “Corp Cultivation Drinks Most of SABMiller’s Water Use,” Environmental Leader, September 13, 2010, http://www.environmentalleader.com/2010/09/13/crop-cultivation-drinks-most-of-sabmillers-water-use/, accessed November 2016.

[4] United States Drought Monitor, July 2015, http://droughtmonitor.unl.edu/MapsAndData/ComparisonSlider.aspx, accessed November 2016.

[5] MillerCoors, 2016 Sustainability Report, p. 7, http://www.millercoors.com/sites/millercoors/files/MC_Sustainability_Report_2016.pdf, accessed November 2016.

[6] MillerCoors, “Environmental Stewardship,” http://www.millercoors.com/sustainability/environmental-stewardship, accessed November 2016.

[7] MillerCoors, 2016 Sustainability Report, p. 7, http://www.millercoors.com/sites/millercoors/files/MC_Sustainability_Report_2016.pdf, accessed November 2016.

[8] MillerCoors LLC, “Sustainability at MillerCoors,” YouTube, published June 8, 2015, https://www.youtube.com/watch?v=j0wSRpSMw-w, accessed November 2016.

[9] New Belgium Brewing Company, “Natural Resource Management Team,” http://www.newbelgium.com/Sustainability/Environmental-Metrics/NaturalResourceManagementTeam, accessed November 2016.

[10] Ceres, “Brewery Climate Declaration,” https://www.ceres.org/declaration/about/climate-declaration-campaigns/brewery, November 2016.

[11] Sierra Nevada Brewing Company, 2015 Sustainability Report, http://www.cdn.sierranevada.com/sites/www.sierranevada.com/files/content/sustainability/reports/SustainabilityReport2015.pdf, accessed November 2016.

[12] Pacific Gas & Electric, “Sierra Nevada Brews Environmental Leadership,” p. 1, http://pge.com/includes/docs/pdfs/mybusiness/energysavingsrebates/incentivesbyindustry/cs_SierraNevada.pdf, accessed November 2016.

[13] Ceres, “Brewery Climate Declaration,” https://www.ceres.org/declaration/about/climate-declaration-campaigns/brewery, November 2016.

[14] Meg Wilcox, “Beer Companies Join Call for Action on Climate Change,” Ceres, March 10, 2015, https://www.ceres.org/press/press-releases/beer-companies-join-call-for-action-on-climate-change, accessed November 2016.

Cheers Hugh! It’s exciting to learn all the things beer companies are doing to offset their environmental impact. Coming from Colorado where there has been a massive rise in micro-breweries over the last several years, I wonder how these smaller companies can also do their part. Things like reducing the water-to-beer ratio used in production seems like a lever that only a mega-beer company could access. Nonetheless, the smaller companies are gaining market share (8% rise in craft beer sales in 2013) and taking big risks for the sake of environmental sustainability, with some even claiming to put their financial returns on the line for the sake of the cause; something that MillerCoors probably couldn’t say. http://www.mintpressnews.com/craft-beer-industry-boldly-brews-with-sustainability-in-mind/203850/

Thanks for the post Hugh! I find this topic really interesting as the underlying climate issues likely affect a number of agricultural products across the entire world. I agree with all the solutions, but particularly like your point about lowering the water/beer ratio and working with growers to lower their water usage. I think another awesome angle for reducing this ratio is the genetic aspect (i.e. engineering crops that use less water), which is being tackled by AB InBev (http://www.forbes.com/sites/taranurin/2016/08/31/in-race-against-climate-change-innovations-to-this-ingredient-could-determine-the-future-of-brewing/#1c1896cf7810). Given the acquisition earlier this year, odds are that there is some form of IP sharing on the topic.

Great post Hugh! Given the fact that most of MillerCoors business comes from sales of their more affordable beer brands, consumer demand for their beer is probably pretty elastic. Other types of beer that have much more taste differentiation will likely have an easier time raising prices when impacts from global climate change really start to kick in. To your point though, MillerCoors clearly has the scale to influence its suppliers to adopt more sustainable practices. I also really like DTeixeira’s point on looking for ways to engineer hops and grain that require less water. I’m sure they’re already investing heavily to find a solution there.

Hugh, thanks for the great post.

I think it shows incredible maturity that so many of these breweries are going so far upstream to address their problems. The investment in solar power generation is not an obvious choice for breweries whose chief concern is water shortages driven by global climate change. The only way investments in for solar panels can directly solve the immediate problem they are facing is if they become a role model for business more broadly, more companies decide to invest in solar, therefore curbing greenhouse gas emissions and resolving the drought that is being caused by climate change. This is the ultimate long game. It would be interesting in addition to learn about how much they are investing in solutions to their immediate short term problem: e.g., development of drought resistant hop varieties, investments in water storage, irrigation, etc..

Thanks again for the great post- hope they continue to push as a leading example for all businesses.

Great read! MillerCoors, as an industry leader, plays a very visible role in the American beer market. It’s great to see that they are taking responsibility for their part in contributing to climate change. I am especially intrigued by the Grower Portal, which connects growers digitally. By doing this, the company actually passes on some responsibility to the growers, involving them in the process of becoming more sustainable and conscious of energy/water usage. Although there isn’t a lot of information available online about this program, it looks like the growers can use a website (http://mcgrowers.com/WebInterface/#/login) to “directly enter information about [their] farming practices as related to sustainability, such as tillage, use of water, fertilizer, etc.” Sharing information and promoting transparency along every step of the supply chain is an important way to efficiently increase sustainable practices among a wider audience. I wonder if MillerCoors could do the same for its consumers—publically encouraging them to use reusable cups and recycle cans. I think you’re absolutely right that MillerCoors should be learning from other breweries and sharing best practices across the industry. As a major player in such an energy and water intensive business, the company has an obligation to publicly endorse sustainable practices!

Thanks for the post, Hugh! I had two thoughts after reading:

1. Given some of the innovative ways that craft brewers are taking on environmental impact in their supply processes, I agree that MillerCoors should be exploring how to integrate some of these practices. One thought was using the more premium craft brands in MillerCoors portfolio as a testing ground for new initiatives as these are likely brands with higher degrees of inelastic demand and, if the changes in processes are communicated to consumers, would likely be valued by the consumers who purchase these more premium craft products.

2. Another opportunity would be a partnership with farmers to decrease the amount of water used in crop irrigation. Through a combination of influence given MillerCoors’ scale and expertise, it’s likely that there are still opportunities to improve the efficiency of crop irrigation to continue to improve the water-to-beer ratio.