The Additive Artisan: Richemont’s Use of 3D Printing in Mechanical Watchmaking

Will Richemont’s investments in 3D printing technology breathe fresh air into an industry steeped in tradition?

Introduction

“There’s something one should expect not only of a watch but also of oneself: to never stand still.”

– Walter Lange, founder of A. Lange & Söhne

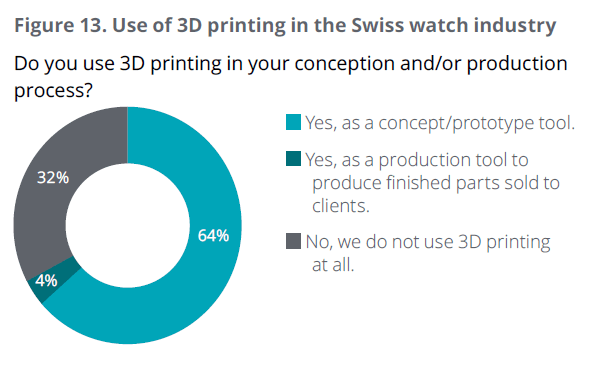

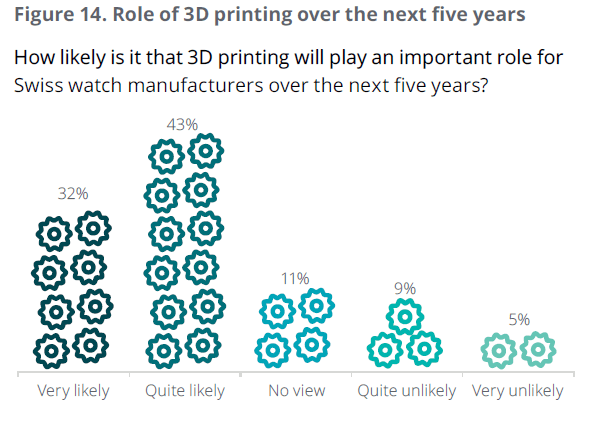

Exports of Swiss watches exceeded $20 billion in 2017[1]. Companies in the space focus heavily on innovation to differentiate their products from those of competitors. One of these innovations is additive manufacturing, or 3D printing, whereby three-dimensional structures are created using computerized processes. Today, over 64% of industry executives indicate that they use 3D printing, while 75% believe that the technology will be important to the industry over the next five years[2]:

Leading the pack is the Compagnie Financière Richemont SA (“Richemont”), which owns brands such as Officine Panerai and A. Lange & Söhne, and has been investing heavily in 3D printing to enhance its production processes and help produce innovative finished products.

Leading the pack is the Compagnie Financière Richemont SA (“Richemont”), which owns brands such as Officine Panerai and A. Lange & Söhne, and has been investing heavily in 3D printing to enhance its production processes and help produce innovative finished products.

However, the use of this technology is still in the early stages, and it is unclear whether it will ever become a driving force in the industry. In a business that prizes artisanal craftsmanship, will Richemont’s efforts be seen as true innovation or mere gimmicks?

The Role of 3D Printing

To create its products, Richemont must develop the hundreds of parts needed for each watch, with the goal of reaching top-notch accuracy without the use of electronics or computers[3]. In addition to telling the time, many of these watches have additional features, or “complications”, which range from a simple date function to mapping the movements of celestial bodies.

After the design process evolved from paper drawings to computer-assisted design (CAD) software, 3D printing components and prototypes was the natural next step. 3D printing “enables experimentation with new shapes and forms otherwise not possible by traditional machining techniques” as well as “quick turnarounds and the ability to produce one-offs without needing to order parts or tools”[4]. The latter benefit is especially important as increasingly discerning consumers demand personalized or bespoke products[5].

Richemont has also begun using 3D printing to produced finished watch components, which have traditionally been reserved for the hands of master watchmakers. Richemont defied that tradition in 2016, when it’s subsidiary brand Officine Panerai introduced the Lo Scienziato Luminor 1950 Tourbillon GMT Titanio, the first watch to use 3D printing for its case construction:

The watch was met with critical acclaim and elevated the brand to the pinnacle of haute horologie[6]. Through this effort, Richemont demonstrated that 3D printing could not only be used for modeling and prototyping, but also for producing high-end, finished components.

What’s next?

In 2014, Richemont and the École Polytechnique Fédérale de Lausanne (EPFL) partnered to create a new academic chair in the school’s Institute of Microengineering, through which Richemont would sponsor research in additive manufacturing[7]. This action further cemented Richemont’s commitment to explore the technology well into the future.

Within this exploration, I would recommend that Richemont focus first on the cost-cutting possibilities. The low tolerances for the accuracy of moving parts, as well as the high standards for the level of finishing on the consumer-facing components, are simply beyond the reach of 3D printing at this time. I believe that Richemont can generate a much greater return on investment in the short-term by focusing on the cost-control side of 3D printing rather than the revenue-generating side.

Only when 3D printing technology improves should Richemont focus on the consumer-facing applications. Even then, I suggest that Richemont begin by educating its consumers on the benefits of 3D printing in its watches, as they may have difficulty appreciating the merit unless it is explained to them in terms of performance (e.g., increased longevity of components) or physical attributes (e.g., material weight).

Still, the biggest question facing the use of this technology is an existential one. If the true value in luxury watches stems from the artisanal craft poured into these products, does 3D printing even have a place in the production process? Will the use of additive manufacturing diminish the human aspect that makes luxury timepieces compelling in the first place?

Word Count: 798

[1] The Swiss and World Watchmaking Industries in 2017. Federation of the Swiss Watch Industry FH, 2018.

[2] The Deloitte Swiss Watch Industry Study 2016: Navigating through Stormy Waters. Deloitte.

[3] Clerizo, Michael. “The Future of Watches: 3-D Printed Cases and Robot Horologists.” Wall Street Journal, 31 July 2018. www.wsj.com, https://www.wsj.com/articles/the-future-of-watches-3-d-printed-cases-and-robot-horologists-1533051950.

[4] Pooler, Michael. “3D Printed Watches Add New Dimension to Time-Telling.” Financial Times, 16 Mar. 2016, https://www.ft.com/content/a623bf8a-d719-11e5-829b-8564e7528e54.

[5] “Swiss Watchmakers Use 3D Printing to Cut Costs of Bespoke Watches.” All3DP, 3 Jan. 2017, https://all3dp.com/could-swiss-watchmakers-use-3d-printing-to-cut-costs-of-bespoke-watches/.

[6] WatchTime, Written. “Future Ready: A Close-Up Look at the Panerai Lo Scienziato.” WatchTime – USA’s No.1 Watch Magazine, 19 Oct. 2018, https://www.watchtime.com/featured/future-ready-a-close-up-look-at-the-panerai-lo-scienziato/.

[7] Compagnie Financière Richemont SA – High Tech for Precision Mechanics Richemont and EPFL to Create a New Academic Chair. https://www.richemont.com/10-press-news/other-group-announcements/371-high-tech-for-precision-mechanics-richemont-and-epfl-to-create-a-new-academic-chair.html. Accessed 13 Nov. 2018.

The true value in luxury watches definitely stems from the artisanal craft, but not only. Even if components are made with 3D printing, luxury watchmakers will still need to design, style and assemble the watches, which is not easy feat! At the end of the day, it’s not the liquid in the bottle that makes Chanel No. 5 what it is, and it’s going to be the same for watches.

Very interesting take on the watch industry. I think that your concern of whether AM would diminish the prestige and allure of the luxury watch is a very fair one. I believe that manufacturers would be taking a significant risk moving in this direction and performance differences (ex. weight) would need to be sufficiently large enough to outweigh any of the perceptions of having created a “cheaper’ watch.

Interesting! I had no idea the watch industry was ahead of the curve in 3D printing. That said, I agree with you that the industry should be weary of undermining the emphasis on artisanal craft.

One tension I was struck by reading your essay is the pros and cons of using 3D printing to cut costs. On the one hand, as you mention this is a great way to improve watch companies’ financials in the short-term. On the other hand, as the price of 3D printing goes down dramatically, this might undermine the value of the end product in the eyes of consumers.

Another interesting thing to think about is the opportunity to use 3D printing to enable further customization (especially with a luxury good like a watch). Increasingly, consumers want customized products (https://www.bain.com/insights/making-it-personal-rules-for-success-in-product-customization/). Curious if you think a watch maker could leverage this technology to produce much more customized watches (very quickly) and how consumers would respond to that.

I think you hit the nail on the head in your last question – will LUXURY pieces lose value? I think yes. Part of luxury is its inaccessibility, craftsmanship, and differentiated quality. I think 3D printing could ultimately get there on the quality but I think it will hurt the first two important parts of this value-creating triology in the luxury market. However, I think outside of luxury 3D printing could be very valuable in mass watch production – in mid-level to aspirational brands but not high luxury. Differentiated technology could create extreme cost-cutting that could flow through to consumers and create additional demand for these products. Manufacturers will need to think carefully about how accessible they wish to make their products – understanding how it will tarnish their standing in the luxury market. I expect watch-makers to utilize this technology on their lower mass-market products and less on their luxury items in order to preserve their value through both craftsmanship and limited attainability.

Found the above article interesting, and left me puzzling the last question as well. Is there a broad enough market for luxury and3D printed watches? Will be luxury brands be able to change perception that 3D printing is still high enough quality and not just a shortcut? Bringing conversations we have had in marketing – can a watch company praise the qualities of hand-made craft AND offer a 3D printed watch? Are these two messages in stark contract?

Thanks for the read. I can’t help but compare luxury watches to luxury cars. As car manufacturing is becoming more and more automated, luxury car makers are going the other way. Rolls-Royce mentions “handmade” in their marketing as it is now a differentiator among all the machine-produced cars. For this reason, I see 3D printing as a design and prototyping tool for the luxury watch industry and nothing else. I think the craftsmanship and handmade nature of these products is what makes them valuable. 3D printing can help in the early stages of production, but I think the final product has to be handmade to remain as valuable.

Great article about a topic you are clearly passionate about. The concern you mention is central to success of 3D printing in the high-end watch industry. Where I do think this has already taken the industry by storm is in the lower end and more mass produced watches such as Swatch. Do you believe this is the case? Also, if 3D printing can remove a big chunk of the artisanal aspect of hand-made watches, and this in turns drive down watch costs, do you think that watch prices will come down? Or will companies be increasingly reliant on their brand to keep prices high and in turn increase their margins.