Space Wars advancing additive manufacturing?

The race to colonize space is spurring rapid application of additive manufacturing

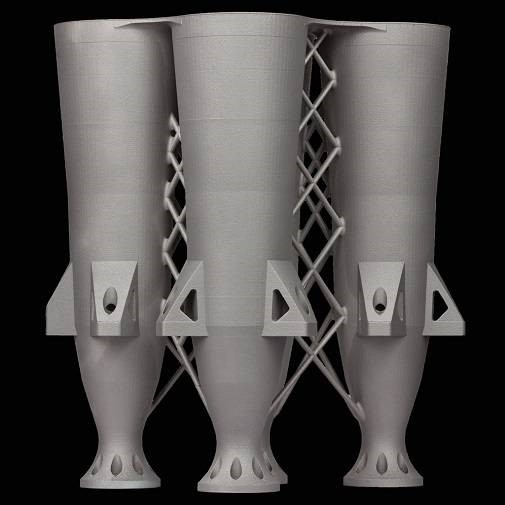

India entered the prestigious ‘heavy-lift rocket club’ in 2017 when the Indian Space Research Organization (ISRO) launched GSAT-19, a communication satellite into space [1]. An exemplary achievement on its own, the mission achieved another quiet victory: it used a 3D-printed radio antenna on the satellite.

Additive manufacturing’s ability to create free-form designs negates the problem caused by traditional machining techniques, reduces complex assembly, and speeds up the process significantly. Further, it offers flexibility of design iterations helping reduce risks and uncertainties and improves product functionality at lower costs. These components are typically built using expensive materials such as titanium, and it is costly to recycle scrap produced during machining. Additive manufacturing can reduce the scrap rate to 10-20% from 80-90%.

For ISRO, which has been looking to break free from its legacy, cumbersome manufacturing processes, additive manufacturing means not just lower costs because of reduced weight of the components, but more importantly, a much faster turnaround time.

In the ongoing global space war, which saw ISRO launch 104 satellites simultaneously in February 2018, the most in history, 3D printed components can potentially add more advantage beyond just lower costs. NASA and the European Space Agency have also been testing 3D-printed parts in space, with each agency trying to turnaround faster space missions.

However, additive manufacturing has its own drawbacks. Manufacturing marginal and thin parts has not been perfected and more work needs to be done to reduce variability, so that additive manufacturing machines can produce components that are identical given the same set of inputs [3]. The economics of manufacturing have not been optimized either as there is a narrow range of highly costly polymers and metal powders used in this process. Scale-up of additive manufacturers has been restrained with no foresight into the volume and complexity of demand. To add to the technical issues, there are several regulatory issues given how nascent this technology is, such as approvals from governments and compliance with safety standards.

To propel investments of time and talent in additive manufacturing in India, ISRO has generated demand by planning a mission to establish colonies on the moon. This will be an unmanned mission that will use 3D printers to manufacture prototypes and structures on the moon using moon dust.

In a bid to further speed up and unleash the sector, ISRO issued bid invites from entities to set up a joint venture of additive manufacturing facilities [5]. This should address all the medium and long-term concerns, with it overseeing the entire process and designing prototypes together, making improvement iterations to solve for issues like variability and perfecting small parts.

Another issue ISRO faces is not having a robust domestic additive manufacturing industry with 101 of the 104 satellites launched foreign manufactured. The Government of India is promoting “Make in India” and importing technology from outside is expensive and prohibitive. To solve for this, ISRO has tied up with state governments to incubate and promote startups in the satellite and space tech sector [6]. In a collaboration between the two, the Kerala state government will set up India’s first of its kind ‘space park’ with the technical support from ISRO.

To execute the vision ISRO has, ISRO needs to build enough capability in the domestic additive manufacturing industry at a low cost to move from building only non-critical components of its satellite to building critical components and eventually all components. Rapid prototyping needs to take place and designs for those must be created immediately. Open innovation or running contests is a fast way to generate new ideas or identify new technologies that can fasten the process. ISRO, as an autonomous government agency could recommend the Government of India to open the space industry for private players [7]. A more competitive landscape would promote more investment in additive manufacturing leading to a faster growth curve.

Having said that, the matter up for the debate is that while the investment in additive manufacturing will benefit ISRO in future missions, should it attempt to manufacture traditionally with its tried and tested model to gain traction in the current space war? And should ISRO invest in captive additive manufacturing rather than depend on third parties? It may take slightly longer than the occurrence of a red moon to know.

(794 words)

References

[1] Ahmad, Samreen, and Alnoor Peermohamed. 2018. “The Future Is 3D”. Accessed November 13. https://www.wiproinfra.com/wp-content/uploads/2018/08/the-future-is-3D-india-witnesses-spurt-in-additive-manufacturing.pdf.

[2] The 3D-printed ‘Feed Cluster’ flying on ISRO’s GST-19 satellite. (https://www.businesstoday.in/technology/news/all-you-need-to-know-about-the-country-first-3d-printed-functional-component-wipro-isro-gsat-19/story/259887.html

[3] J.B. Roca et al., Getting past the hype about 3-D printing. MIT Sloan Management Review 58, no. 3 (Spring 2017): 57–62.

[4] NDTV. 2018. SRO Moon Mission: Indian Space Research Organisation Will Try To Build Igloo-Like Shelters. Image. http://gloo-Like Habitats’ On Moon: Indian Space Agency ISRO’s New Mission.

[5] ISRO. 2017. “General Terms For Expression Of Interest For Setting Up And Operation Of Additive Manufacturing, Metal 3D Printing Facility At LPSC Valiamala On BOOT Model”. https://www.isro.gov.in/sites/default/files/tenders/eoi_tm20_030283_eoi_for_setting_up_of_3d_printing_facility.pdf.

[6] Chaudhary, Suman. 2018. “ISRO, Kerala Tie-Up To Incubate And Promote Startups In Satellite, Spacetech Sector”. Indian Web2, , 2018. https://www.indianweb2.com/2018/03/19/isro-kerala-tie-up-to-incubate-and-promote-startups-in-satellite-spacetech-sector/.

[7] ISRO and the business of space. 2017. “ISRO And The Business Of Space”, , 2017. https://www.newslaundry.com/2017/04/18/isro-and-the-business-of-space.

Fascinating topic Starwars – I agree 3D printing will become a crucial aspect of space exploration and colonization. NASA is also pursuing several avenues of research around 3D printing, including turning space station waste into 3D printing filament. They are also exploring 3D printed habitats as well, which theoretically could be built on Mars even before humans step foot on the planet. That said, until the economics become more attractive I envision 3D printing more likely serving as a solution for emergency situations (e.g., a part has broken and needs to be replaced).

The interest in space exploration has decreased significantly since the late 1960’s and early 1970’s – no man has been on the moon in over 45 years! However, Elon Musk (SpaceX) and Jeff Bezos (Blue Origin) have reinvigorated the public interest in space exploration and will hopefully continue to drive innovation in the industry forward. 3D printing will almost certainly play a role in the future of space travel.

Terrific topic and I absolutely believe additive manufacturing has the potential to truly transform a variety of industries. That said, given the current state of the technology, I don’t think ISRO should go all in on its own captive manufacturing capabilities. The risks at this time are just too large given the government, safety regulations, and idiosyncratic risk of a rocket launch. As you correctly stated, additive manufacturing still has difficulties producing uniform parts with the same molecular composition. ISRO should begin to incorporate to proven parts and process from 3rd party partners and allow them to shoulder that risk but wait until the process is at a more established state to build out proprietary capabilities.

With an eye towards the future, the most impressive value of additive manufacturing is to source local materials to build structures and components. In this way, ISRO need not ship a colony of structures to the moon – only the additive manufacturing machines to produce those structures. It also has tremendous value in providing emergency just in time repairs for critical components in austere locations – such as a space station.

As you wrote, additive manufacturing has shown tremendous potential and the Indian government has sent a powerful message by setting a goal of using additive manufacturing on the moon. I would be curious to learn more about the mechanics of accomplishing such a task. How soon before additive manufacturing will pay for itself in this sector? Additionally, will India continue to rely on 3rd parties to transport its materials into space? Additionally, what benefits may be realized as the additive manufacturing technology improves to be able to use a greater variety of materials to build structures in harsh environments. Finally, in the high stakes realm of space transportation, will open innovation solutions be precise enough to be useful? I am excited to see how it turns out.

There is no question that 3D printing will lead to significant innovation in the space industry. The biggest concern I have however, stems from one sentence in your article.

“This will be an unmanned mission that will use 3D printers to manufacture prototypes and structures on the moon using moon dust.”

Printing new parts in space is truly something out of science fiction and I believe it will be the only way to successfully manufacture in the interim period between exploration and colonization of a new planet or moon. The biggest issue however, is the significant weight and therefore cost of carrying the raw material input to the process. To 3D print a metal part, the metal input material still must be launched into space, adding weight to the spacecraft. Unless companies can use existing space material such a moon dust or material from metallic asteroid, the marginal benefit of 3D printing in space will be much lower. If I were ISRO, I’d spend my money on funding research into novel inputs into the process using existing natural resources from space.

To address your question and react to John’s comment, it seems to me that there are two potential use cases for applying the 3D printing technology to space exploration. The first is manufacturing certain components used to build parts of the ship or tools for the mission. The second is to manufacture those components in space. I think in the short term the benefits of developing this technology for manufacturing on earth is very clear: they reduce costs vs traditional manufacturing methods and decrease the speed of production via easy iteration. For me, that’s enough reason to invest in the technology today. As John mentioned above, the long game would be to make it viable in space with the raw materials available off earth.