Printing [War]Toys: Military’s Use of 3-D Printing to Improve Supply Chain

3-D Printing has the potential to significantly impact the military's supply chain: it can significantly reduce their costs, lead times, and inventory levels. Some even say that as the technology improves, it will disrupt the Military-Industrial complex.

The Defense Logistics Agency

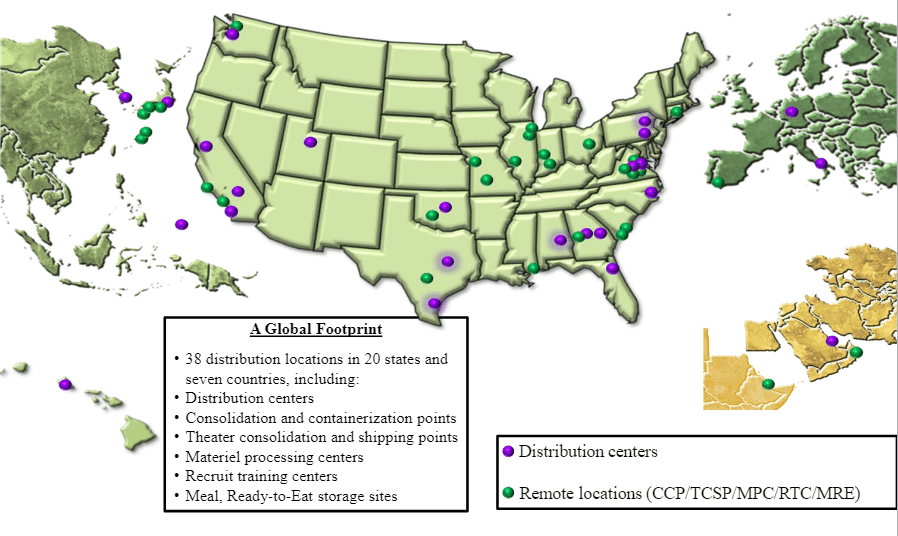

“With about 5 million distinct consumable, expendable, and reparable goods” distributed worldwide, The U.S. military’s Defense Logistics Agency (DLA) is one of the most complex logistics organizations in the world. According to their website, they provide more than $34 Billion in goods and service[1]. From 2005 through 2013, DLA disposed an average of over $1 billion in items per year.[2] DLA needs to keep stock of all sorts of items, and some items are difficult to forecast whether they will ever be used. Because of its complexity, it’s important for taxpayers to know how the armed services are addressing these issues and how they can benefit in the digital age to make better decisions and have a more agile and lean warehousing and procurement network.

DLA’s Strategic Plan

According to DLA’s Strategic Plan (2015-2022): “implementation of robotic technologies, automation in distribution operations, and 3D printing of hard-to-source and long-lead-time parts will enhance logistics support capabilities and produce more reliable, cost-effective solutions”[3]. To this end, DLA has taken several initiatives to create a more agile supply chain and be more responsive to their first goal in the strategic plan: “Warfighter First.”

Additive Manufacturing

Additive manufacturing or 3D printing has been around for more than 30 years but as costs for 3-D printing machines have gone down, they have become useful for many industries. To 3-D print a design, a machine starts with a computerized design and the material used for additive printing, which can be polymer, metals, or even concrete. The process for 3-D printing can be slow, and the size of the machine limits the size of the printed item. Furthermore, it still requires human intervention, but future innovations may make this technology fully autonomous[4].

DLA’s Uses of Additive Manufacturing

DLA and other government agencies have begun experimenting with 3-D printing and finding a potential for the technology going into the future. There is already a 3-D printer inside the USS Harry Truman[5] and even a zero-gravity 3-D printer in the International Space Station[6].

These machines allow members of the armed forces to create rare parts or items on demand which they may not have available now. The Air Force has been using 3-D printing to create parts for planes no longer in production by using cold spray printing to create or repair the damaged parts. A video explanation of this process below: https://youtu.be/arBsyex1Mmc

Acquiring a panel for an out of production B-1 Lancer Bomber could take as long as 18 months and cost around $225,000 per part to repair whereas additive manufacturing produces this is a fraction of the time and the cost.

The Future of Additive Manufacturing for the Armed Forces

DLA plans to continue experimenting with new ways to implement 3-D printing technology. The Army Research Lab (ARL) has experimented with 3-D printing weapons and creating customized UAVs (quadcopters) on-the-fly and custom-made for the specific mission[7]. The ARL’s Center for Cold Spray has two systems for prototyping and four portable systems for field use.[8] In 2012, they began deploying expeditionary labs which contain 3-D printers, CAD workstations, and printing materials. In the future, more complex 3-D printing facilities will be deployed to the field, and available blueprints will increase as DLA creates “a repeatable process to identify parts that are suitable for additive manufacturing.”[9] These initiatives will greatly compress the supply chain for spare parts and will allow DLA to have real just-in-time inventory.

Areas of Opportunity for DLA’s Additive Manufacturing Initiatives

One of the key challenges for additive manufacturing is having the models available and the necessary equipment. As manufacturers increasingly embrace 3-D printing technology, the military services should leverage its position to ensure that contracts for new vehicles produced come with the necessary blueprints to print parts on the fly rather than storing spare parts. The savings they could make from inventory reductions or spare parts procurement costs could finance more 3D printer purchases which DLA can deploy to key areas around the world. In an article on 3Dprint.com, Scott Grunewald suggests that “technologies like 3D laser mapping can reverse engineer or even make improvements to aging parts in-house.”[10] Using both approaches may allow DLA to have a sufficiently large library of parts which they can use to reduce future inventory levels, their associated holding costs, and make an extremely efficient supply chain.

Questions:

How can DOD encourage manufacturers to adapt and to leverage the partnerships throughout long-term contracts considering the need for replacement parts will be limited?

What sort of challenges may impede the adoption of Additive Manufacturing by the armed forces?

(768 words)

References

[1] Defense Logistics Agency Fact Sheet. 2017. Ebook. Fort Belvoir, VA: DLA Public Affairs Office. http://www.dla.mil/Portals/104/Documents/Headquarters/DLA%20At%20A%20Glance/DLA%20Fact%20Sheet%20June%202017.pdf

[2]Peltz, Eric, Amy Cox, Edward Chan, George Hart, Daniel Sommerhauser, Caitlin Hawkins, and Kathryn Connor. 2015. Improving DLA Supply Chain Agility. Ebook. Santa Monica, CA: Rand Corporation.

[3] “Defense Logistics Agency: Strategic Plan 2015-2022”. 2015. http://www.dla.mil/Portals/104/Documents/J5StrategicPlansPolicy/Strategic_Plan_201_web.pdf, , 2015.

[4] Attaran, Mohsen, and Paisley Stidham. 2017. “The Coming Age Of 3-D Printing”. Industrial Management 49 (4).

[5] Millsaps, Bridget. 2017. “Experimental Fab Labs Set Up On USS Harry Truman & USS Kearsarge Allow For Self-Sustainability At Sea”. 3Dprint.Com | The Voice Of 3D Printing / Additive Manufacturing. https://3dprint.com/112962/fab-labs-uss-harry-truman/.

[6] “Complex Parts Manufactured In Space Deliver New Capabilities”. 2017. Medium. https://medium.com/made-in-space/complex-parts-manufactured-in-space-deliver-new-capabilities-8848ac02c9e9.

[7] Matthews, William. 2017. “Custom Made”. National Guard Magazine , 2017.

[8] “ARL Center For Cold Spray | U.S. Army Research Laboratory”. 2017. Arl.Army.Mil. https://www.arl.army.mil/www/default.cfm?page=369.

[9] “3D Printing Could Help DLA Cut Costs, Improve Parts Support”. 2017. Defense Logistics Agency. http://www.dla.mil/AboutDLA/News/NewsArticleView/Article/615987/3d-printing-could-help-dla-cut-costs-improve-parts-support/.

[10] Grunewald, Scott. 2017. “US Air Force Developing Strategy Increased Role For 3D Printing In Aircraft Design & Maintenance”. 3Dprint.Com | The Voice Of 3D Printing / Additive Manufacturing. https://3dprint.com/101689/us-air-force-increased-3dp/.

Thanks Alvaro! This concept is very interesting, but I see two main challenges that may inhibit the use of 3D printing for defense applications. Firstly, 3D printing may represent a security concern, which could be more relevant than flexible demand considering the industry we are in. In order to print parts the digital designs need to be accessed (or more likely stored) locally. These design often include very relevant trade secrets which could pose a competitive advantage in a confrontation. The risk of someone accessing the local hardware in a region of conflict seems to be quite high. Therefore, the IT security in place should be sufficiently sophisticated before attempting 3D printing.

Secondly, supply chain challenges still exist even with 3D printing. Additive manufacturing allows customized production of varying designs, but the input of raw materials is similar to other forms of manufacturing. Thus, the timely supply and appropriate storage of raw materials still needs to be managed