Levi Strauss & Co. does not want you to wash your Levi’s 501 pair of jeans!

Levi Strauss & Co., the American denim clothing company, is both a victim and victimizer in the worldwide water crises. What are they doing about it?

Why should we care about water pollution and scarcity?

Since 2005, the World Economic Forum (WEF) has published an annual report on The Global Risks Landscape about the challenges affecting the global economy. Of the 28 risks selected, which are organized in 5 different categories (e.g., geopolitical, societal, economic, environmental, technological), the WEF selected the water crises as the risk with the highest potentially devastating impact for several countries or industries within the next 10 years[1]. In a nutshell, water pollution and scarcity is the greatest risk to the global economy.

Why Levi Strauss & Co. is both a victim and victimizer in the water crises?

Levi Strauss & Co. (LS&Co.), the American denim clothing company, is not only negatively affected by water scarcity, but it is also, given its supply chain and manufacturing processes, a contributor to the problem.

Levi Strauss & Co. as a victim: Water scarcity decreases cotton crop yields, making the price spike, affecting the cost of goods sold, ultimately affecting profitability. According to the U.S. Department of Agriculture’s 2016 – 2017 world cotton projections, cotton demand will exceed supply for the second consecutive year, increasing cotton prices. This delta has been mainly driven by China’s production drop over the last several years and India’s 2015 production decline, mainly due to climate issues. [2] [3]

Levi Strauss & Co. as a victimizer: In order to further understand (and quantify!) how they are contributing to water pollution and scarcity, in 2007 and in 2015, L&Co. commissioned the apparel industry’s first all-inclusive lifecycle assessment (LCA) focused on their emblematic pair of Levi’s 501® medium stone wash jeans. What did they learn? Levi’s 501 jeans’ entire lifecycle uses 3,781 liters of water (equivalent to 3 days’ worth of one US household’s total water needs)![4]

The study analyzed eight areas of the pair of jeans production: cotton production, fabric production, garment manufacturing, packaging, sundried, transportation. Given that they learned that 68% of the water consumed in the lifecycle is used in the cotton production stage and 23% in consumer care, they prioritized strategic and operational initiatives in these two stages. That been said, they launched initiatives to decrease water consumption in garment manufacturing (1% of overall water consumption). [5]

…so, what are they doing to decrease water consumption in cotton production? consumer care? garment manufacturing?

Better Cotton Initiative. In order to address that ~70% of the water consumed in the lifecycle is used in crop production, and given that ~95% of LS&Co. products are cotton-based, the company co-founded the Better Cotton Initiative (BCI). BCI aims to make global cotton production better for farmers (improving labor standards and improving livelihood), better for the environment and for the overall industry. [6]

BCI farmers use up to 18% less water than non-BCI farmers. In 2015, LS&Co. sourced 12% total cotton through BCI, increasing by 71% compared to 2014. By 2020, their goal is to use 100% sustainable cotton through BCI and recycled cotton.[7]

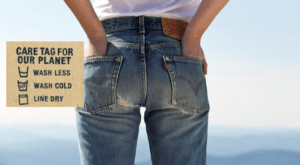

Wash Less/Wash Cold/Line Dry. LS&Co.’s LCA consumer insights found that washing every 10 times Levi’s 501 pair of jeans are worn instead of every 2 times reduces energy, climate change impact, and water consumption by 80%. [8]

The company has launched marketing campaigns like the one below to motivate their consumers to decrease their water consumption when washing their pair of jeans.

Levi’s Water<Less. LS&Co.’s launched an internal program to make designers come up with new innovative ways to get the denim finishes that the clients want, but using a lot less water! So far, the organization has saved 1 billion liters of water by reducing up to 96% of the water in the denim finishing process. Currently, 40% of all Levi’s jeans are made under Levi’s Water<Less rubric. The company aims that by 2020, 80% of their jeans will be made under this program. [9]

What else can be done?

LS&Co. can increase the scale of their impact by rolling-out their sustainability initiatives within the organization and by being a catalyst leader in the apparel industry (recycled fabrics?).

Internal scale. Even though the organization has shown true commitment and impact in reducing their water consumption, only 1 out of their ~80 manufacturing[10] companies has rolled out the Levi’s Water<Less manufacturing program. They should roll out these program to more of the plants!

Apparel catalyst leader. LS&Co. should partner with other industry leaders to push the industry forward on recycling fabrics. Given the water consumption of the industry, that is going to be the long-run solution. According to The Global Leadership Award in Sustainable Apparel (GlASA), on average, approximately 100 to 150 liters of water are needed to process 1 kilogram of textile material. And an estimated 5 trillion liters of water, the equivalent of 2 million Olympic swimming pools, are used each year to dye 28 billion kilograms of textiles.[11]

(798 words)

[1] World Economic Forum, “The 2015th Edition of Global Risks”, http://reports.weforum.org/global-risks-2015/, accessed November 2016.

[2] United States Department of Agriculture, “The World and United States Cotton Outlook”, http://www.usda.gov/oce/forum/2016_speeches/Cotton_Outlook_2016.pdf, accessed November 2016.

[3] The Economic Times, “Cotton prices may not decline till arrival of new crop: India Ratings” http://economictimes.indiatimes.com/news/economy/agriculture/cotton-prices-may-not-decline-till-arrival-of-new-crop-india-ratings/articleshow/53318574.cms, accessed November 2016.

[4] Levi Strauss & Co. “The life cycle of a jean: Understanding the environmental impact of a pair of Levi’s 501 jeans”. http://levistrauss.com/wp-content/uploads/sites/4/2015/03/Full-LCA-Results-Deck-FINAL.pdf, accessed November 2016.

[5] Ibid

[6] Better Cotton Initiative website. http://bettercotton.org/about-bci/, accessed November 2016.

[7] Levi Strauss & Co. Sustanaibilty website. http://levistrauss.com/sustainability/planet/, accessed November 2016.

[8] Levi Strauss & Co. “The life cycle of a jean: Understanding the environmental impact of a pair of Levi’s 501 jeans”. http://levistrauss.com/wp-content/uploads/sites/4/2015/03/Full-LCA-Results-Deck-FINAL.pdf, accessed November 2016.

[9] Ibid.

[10] Levi Strauss & Co. Sustanaibilty website. http://levistrauss.com/sustainability/planet/, accessed November 2016.

[11] The Global Leadership Award in Sustainability Apparel website. “The State of The Apparel Sector 2015 Special Report”, http://glasaaward.org/wp-content/uploads/sites/4/2015/05/GLASA_2015_StateofApparelSector_SpecialReport_Water_150624.pdf, accessed November 2016.

I found Levis’ strategy of engaging their end-consumers’ to help them reduce water usage was really creative and leveraging one of their core competencies – marketing. This helps define their brand as environmentally friendly and empowers consumers to feel like they are doing their part, while not impacting their existing operating or business model. By asking consumers to be more mindful when washing their jeans, Levis accrues no additional cost besides the initial market. But I agree, I don’t believe that alone is enough, making both production innovation and enforcing sustainability standards on suppliers will be key. However, I wonder if product innovation with recyclable materials would have an impact on their operating model. Would Levis have to develop a new R&D team? Or would Levis become dependent and rely on external partners for expertise?

I really liked how you addressed both parts of Levi’s model – both their use as a producer and the use of their customers. It sounds like Levi’s has taken some real and definite steps on their production side of the house, although I agree that the <Less campaign needs drastic expansion to remain a selling point. One big question that came up for me while reading your post was whether or not Levi's has done any studies on if their marketing campaign has actually had an effect on their consumers' behaviors. In a quick google search on the topic, I found one academic paper studying the effect but sadly couldn't review it without paying for access. That said, several news organizations have praised Levi's for the move and it has been named one of the most innovative companies for the campaign. If you have access to any data on consumer behavior change, I'd love to learn more!

I appreciated your insight that the problem of water scarcity is not just a PR risk for Levi’s but also a problem they face in the long term viability of their supply chain. Unlike many companies that pursue sustainability as an add-on to their business for optical reasons, Levi’s is authentic in its pursuit of resource conservation because it is truly aligned with its business model. The declines in crop yields for cotton made me think about Indigo Agriculture — perhaps there’s a partnership in the making with Levi’s! However, this would require Levi’s taking more control of its supply chain and/or becoming vertically integrated.

This is a topic really close to my heart. Pakistan is a major producer for Levi’s (raw and finished good) and is one of the countries destined for an enormous water shortage imminently, particularly due to conflict with their neighbours on the usage of water upstream. I am inspired by Levi’s focus on the consumer as it is undoubtedly the place where change can truly happen. In fact, I find myself washing my denims lesser since I heard about how not washing them actually preserves them and their colour for longer. One has to question though whether there is an inherent conflict of objectives there: use less water -> jeans last longer -> buy less jeans -> make less jeans -> less profit? I commend the company for thriving to find a sustainable solution.

On the production side, there is yet more work to do, especially in environments like Southeast Asia, where regulatory players are often weak and corrupt, and it can be more costly still for companies to do the right thing for long term sustainability, and traceability is incredibly complex to achieve.

This is a really thought-provoking issue, and I am glad to read that Levi’s is doing something about water conservation! The idea of putting the responsibility partially on the consumer is an interesting proposition. Although Levi’s is actively attempting to decrease its water usage, using strategic marketing initiatives like the ad you referenced both educates the public about water consumption while also making the consumer accountable for their portion of water use after the company has relinquished control of the product. Their website (http://store.levi.com/waterless/doingyourpart.html) even lays out the results of a challenge reporting how consumers could use less water in their lives, further quantifying the issue in simple terms such as the number of untaken showers, unwashed jeans, and reused water bottles. It’s interesting that Levi’s is also placing responsibility on designers, challenging them to also use less water in the denim finishing process. Overall, these initiatives are innovative ways to improve internal processes while also addressing other parts of the business outside of Levi’s control, such as the designer and consumer.

Great post! The part that most interested me was the Better Cotton Initiative (BCI). I was curious to know exactly how they were making cotton farming more sustainable or if it was just a PR stunt with little impact. BCI actually has a lot of corporate sponsors (including IKEA). Overall, I found the program was addressing a lot of areas in regards to sustainable cotton.

However, from a water conservation perspective, I found the BCI to be lacking – it also took several click-thrus to get to any information of value. The only items they discuss in regards to “conservation of water” are that farmers with irrigation-fed farms should: 1) consider all points where water is moved in the irrigation system, 2) Optimize water storage, water delivery and irrigation of crop, and 3) manage salinity of the water. For rain-fed, farmers should focus on capturing water and preventing erosion. Reviewing the auditing standards, it appears farmers are only required to report their water use to meet the water principle. There is no auditing of actual practices. Overall, it seems like the program is fairly lax, but it is a step in the right direction.

Source: http://bettercotton.org/. Accessed November 6, 2016.

Really interesting that Levi’s is trying to influence customer behavior to reduce energy use. I have read about a number of companies that have tried such initiatives, such as Marks & Spencer, which reduced the recommended water temperature at which their clothes need to be washed on all their clothing labels. I think it’s also important for apparel companies to continue to innovate in their fabrics so that customers can engage with them in a way that is less wasteful (e.g. longer durability, less washing required, sweaters that are warmer with less fabric required, etc.) I wonder if Levi’s is pursuing any kind of innovation in their denim fabrics to encourage fewer washes (e.g. easy stain removal, anti-odor technology) – otherwise, getting people to wash their clothes less is a hard sell for personal hygiene!

Levis has done a really good job in identifying its impact on the environment and not only act on its own areas of accountability (supply chain) but also encourage its consumers to act on their own area of responsibility (wash less campaign). It makes the issue much more visible and encourages collaboration around it.

It reminds me of the strategy of a French popular denim brand called APC (http://www.apc.fr/) which has taken a step even further by marketing that not washing your denim jeans is the way to go to be cool & fashionable. When you buy a pair of jeans from them it comes with guiding instructions on how to take care of the jeans and how you should never wash it if you are a purist. It’s a fun and engaging way to make customers work towards changing behaviors and make them more conscious of the environment.

They also developed a program whereby you can always resell you worn jeans in their stores whenever you want to get rid of it. They have set up a “vintage” section in each of their stores where they resell those second-hand jeans for a fraction of the price. With this program they encourages customers to recycle their used items . The program aims as tackling the issues of non recycled fashion items which customers usually throw away. Knowing that only 1/4th of used fashion items only get recycled today, Levis could try to replicate this program at scale as another initiative to limit their impact on the environment.

I am very impressed by Levi’s two-pronged approach to reducing water consumption by targeting their own practices as well as their consumers’ behavior. I feel that most companies put in a lot of effort and resources to improve the sustainability of their own business practices, but often place little emphasis on what happens once their product or service has been passed on to the next party. In general, I would not have really thought of the garment industry as being a big culprit in global water consumption (1% of overall consumption!), so I think it is powerful that Levi’s is taking a stand to lead change in this industry. That being said, I am admittedly a bit skeptical that Levi’s is truly holding up their end of the deal based on the point that they have only implemented this initiative in one of their manufacturing facilities. Similarly, part of me struggles with whether or not this is simply an initiative to cut their own production costs as opposed to truly advocating for more sustainable water consumption practices in the industry.

As a big levi’s fan, it warms my heart to see this is front of mind for them.

I wonder, what is it about BCI farmers that leads to them using less water? Is it simply more responsible irrigation? Do they use more resilient strains of cotton?

Some of my favorite levis are ones that blend in other fibers–like elastane–that actually make the jeans more comfortable. I wonder, what does that do to the durability and water footprint of those jeans? Is cotton the lesser of all evils when it comes to fabrics, or would changing their blend to more synthetics / other fibers be better?

What a great post Camilla, I hadn’t thought of how the clothing industry might me impacted by climate change. It’s quite staggering that one pair of 501s uses 3,781 liters of water! I’ve also seen the campaigns targeted at getting consumers to wash jeans less frequently and never connected that the campaign was a part of their initiative to help decrease the impact their jeans have on the world. That being said, I think the BCI initiative is a bit weak. Given that 70% of water consumption comes from the production of the cotton used to make jeans itself; there is a lot of room for improvement given those part of the initiative use only 18% less water. I’m excited to see what happens when they really start expanding their products to use other materials besides cotton.