Is Diageo feeling blue about Johnnie Walker’s future? Declines in grain yields could threaten the world’s largest spirit producer’s supply chain

Anticipating risk to its agricultural raw materials, Diageo has taken steps to ensure the sustainability of its supply chain. Have they done enough?

Source: ScotchMaltWhiskey, “How Whiskey is Made,” YouTube, published January 16, 2013, https://www.youtube.com/watch?v=7VSj9xaNWpw, accessed November 2017.

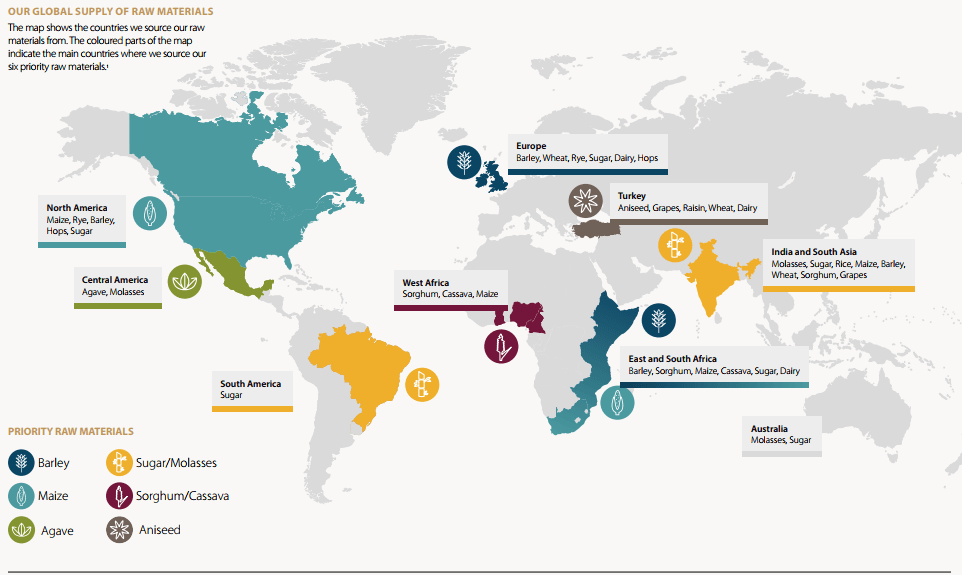

As the long Boston winter sets in, many HBS students find warmth in a glass of Talisker, Bulleit, Baileys, or even Rumple Minze, which is especially well-suited for the holidays. These drinks, and dozens of others, are manufactured by the British alcohol behemoth Diageo [1]. Like all alcoholic beverage producers, Diageo relies on agricultural products for many of its raw materials, as grains/cereals provide the sugar which yeast convert into the ethanol that gives Diageo’s brands their potency [2]. With Diageo’s scale and global presence (Figure 1), it requires a global supply chain which faces significant challenges in the coming decades.

Figure 1: Diageo’s Raw Material Supply

Source: Diageo, Building Sustainable Supply Chains: Our Strategy For Sustainable Agriculture, pg. 4, https://www.diageo.com/pr1346/aws/media/1379/diageo_sustainable_agriculture_strategy_july2016.pdf, accessed November 2017.

The Problem

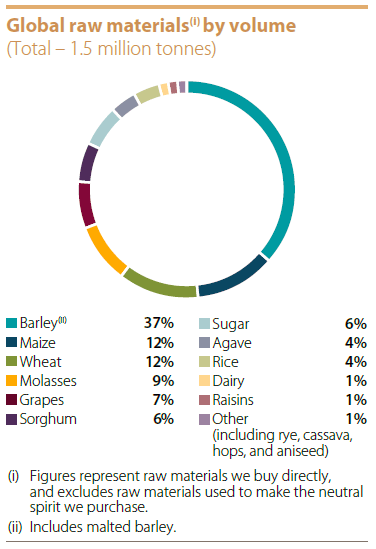

Accounting for over 50% of its inputs by volume, barley, maize, and wheat are the company’s three primary sugar sources [3] (Figure 2). Like many organizations depending on agricultural products, Diageo is susceptible to supply chain risk resulting from ongoing climate change, with one source suggesting the company may see a $77 million dollar increase in raw material costs due to disruption in production and higher commodity costs [4]. While potentially less vulnerable to climate change than crops such as rice [5], these Diageo staples are at risk of significant yield declines in coming decades [6]. Yields of wheat, which Diageo uses in its Smirnoff Vodka and Tanqueray Gin, are expected to decline by as much as 21% this century [6]. Moreover, yields of barley, the base ingredient in Diageo’s beer brands and many of its whiskeys including Johnnie Walker, J&B, and Lagavulin, may decline by up to 33.6% for spring barley and 17.3% for winter barley [6]. Assuming grain demand and consumption of alcoholic beverages remain constant, the decline in yields is likely to increase Diageo’s grain costs in the future. Scarcity of other inputs, especially fresh water, will also present significant challenges to Diageo’s future production [7].

Figure 2: Breakdown of Diageo’s Raw Materials

Source: Diageo, 2017 Annual Report, p. 47, https://www.diageo.com/pr1346/aws/media/3960/diageo-2017-annual-report.pdf, accessed November 2017.

What Are They Doing About It?

Spending approximately £300 million on agricultural produce each year [8], Diageo recognizes that they “have a clear commercial interest in ensuring that all [their] supply chains are sustainable.” [9] In the short term, Diageo is seeking “to source 80% of agricultural raw materials locally by 2020” in some locations, claiming that local sourcing will be better for the farming communities and the sustainability of its supply chain [10]. According to the company, “without a reliable source of high quality raw materials, we will struggle to make the iconic brands that are core to our business.” [11] As part of this initiative, the company will work with local farmers to improve drought resilience, as seen in a pilot program conducted with barley farmers in Tanzania [10]. Over the long term, Diageo plans to increase its use of sorghum and cassava, which are more resistant to climate change [9]. Diageo also expects to continue training farmers on subjects such as “soil testing, crop insurance, fertiliser use, [and] mechanisation.” [12] In some cases, Diageo has helped farmers improve yields by as much as 100% [12]. Diageo also plans to develop key performance indicators for its priority crops [13]. Doing so will allow the company to measure and report on progress with its supply chain initiatives and make improvements for further expansions of its programs.

What Else Can They Do?

Because water is the main ingredient in every one of its products, Diageo has rightly focused most of its efforts involving its supply chain on improving water efficiency [14]. However, as it tries to grow many of its premium brands, which are likely less amenable to recipe changes, Diageo may need to focus more on its supply of grains than it has to this point. One option may be to invest in new technologies to improve crops’ resistance to drought and other features of climate change. Additionally, Diageo must continue investing in operational improvements to reduce raw material waste in its production processes. Many of its premium brands, such as Lagavulin, are still produced using traditional methods [15] which, while very important to marketing, may not be as efficient as more modern methods. Finally, Diageo may need to consider changing some of its recipes to use cheaper and more sustainable sugar sources. This may prove to be difficult given the often-strict standards required to label a spirit with a given name (e.g. “bourbon”).

Unknowns

As the effects of climate change materialize, it will interesting to see if Diageo can simply pass on its cost increases to consumers. Demand for its premium products may be relatively inelastic. It is also unclear whether Diageo will choose to vertically integrate around its grain and cereal inputs, as it has with agave. In the next several years, Diageo expects to own and grow approximately 70% of its agave plants [16]. Such changes may lead to further cost savings and yield increases that could counteract the effects of climate change. Finally, in response to decreased supply and higher prices, it may be possible that farmers simply allocate more acreage to growing barley, wheat, and other necessary grains.

(800 words)

References

- Diageo, “Explore Our Brands,” https://www.diageo.com/en/our-brands/brand-explorer/, accessed November 2017.

- Bill Rowland, “Distillation Basics: How Liquor is Made,” The Cocktail Novice, July 3, 2014, https://thecocktailnovice.com/distillation-basics-how-liquor-is-made/, accessed November 2017.

- Diageo, 2017 Annual Report, p. 47, https://www.diageo.com/pr1346/aws/media/3960/diageo-2017-annual-report.pdf, accessed November 2017.

- Frances Way, “Food and drink found to be ignoring biggest impact on climate,” The Guardian, September 3, 2015, https://www.theguardian.com/sustainable-business/2015/sep/03/biggest-food-drink-companies-ignoring-climate-impacts-supply-chain, accessed November 2017.

- Richard Gledhill, Dan Hamza-Goodacre, Lit Ping Low, “Business-not-as-usual: Tackling the impact of climate change on supply chain risk,” PWC, https://www.pwc.com/gx/en/services/advisory/consulting/risk/resilience/publications/business-not-as-usual.html, Accessed November 2017.

- Matthew Gammans, Pierre Mérel, Ariel, Ortiz-Bobea, “Negative impacts of climate change on cereal yields: Statistical evidence from France,” Environmental Research Letters 12, 054007 (2017): 1, 5. IOPscience via ProQuest, accessed November 2017.

- Diageo, Sustainability and Responsibility Performance Addendum to the Annual Report 2017, p. 40, https://www.diageo.com/pr1346/aws/media/3944/diageo-2017-sustainability-and-responsibility-performance-addendum.pdf, accessed November 2017.

- Diageo, Building Sustainable Supply Chains: Our Strategy For Sustainable Agriculture, pg. 2, https://www.diageo.com/pr1346/aws/media/1379/diageo_sustainable_agriculture_strategy_july2016.pdf, accessed November 2017.

- Diageo, “Sustainable supply chains,” https://www.diageo.com/en/in-society/building-thriving-communities/sustainable-supply-chains/, accessed November 2017.

- Diageo, 2017 Annual Report, p. 32, https://www.diageo.com/pr1346/aws/media/3960/diageo-2017-annual-report.pdf, accessed November 2017.

- Diageo, Building Sustainable Supply Chains: Our Strategy For Sustainable Agriculture, pg. 5, https://www.diageo.com/pr1346/aws/media/1379/diageo_sustainable_agriculture_strategy_july2016.pdf, accessed November 2017.

- Diageo, Building Sustainable Supply Chains: Our Strategy For Sustainable Agriculture, pg. 10, https://www.diageo.com/pr1346/aws/media/1379/diageo_sustainable_agriculture_strategy_july2016.pdf, accessed November 2017.

- Diageo, Building Sustainable Supply Chains: Our Strategy For Sustainable Agriculture, pg. 13, https://www.diageo.com/pr1346/aws/media/1379/diageo_sustainable_agriculture_strategy_july2016.pdf, accessed November 2017.

- Diageo, 2017 Annual Report, p. 7 & 15, https://www.diageo.com/pr1346/aws/media/3960/diageo-2017-annual-report.pdf, accessed November 2017.

- “Port Ellen Distillery & Maltings,” Islay Info, http://www.islayinfo.com/islay_portellen_maltings.html, accessed November 2017.

- Diageo, Building Sustainable Supply Chains: Our Strategy For Sustainable Agriculture, pg. 12, https://www.diageo.com/pr1346/aws/media/1379/diageo_sustainable_agriculture_strategy_july2016.pdf, accessed November 2017.

I think there are 2 questions that you address in this very interesting article and I wanted to add a couple of additional insights:

1- How can Diageo react/hedge to the declining yields and increase in price its main raw materials?

I see two additional actions that Diageo could take in order to hedge against this trend. a) Diageo could increase its use of financial instruments to hedge against the increase in price. For instance, it could buy future contracts on its main raw materials to lock in the prices. That way, Diageo could plan at least how big will the increase in price be and quantify the efficiencies it will have to make to cover the increase in cost. More sophisticated financial hedging strategies could additionally help Diageo, such as more complex financial instruments that pay off when the price of raw materials increase. b) Diageo could further diversify its raw material sourcing. In the short term this might increase the price since less volume is bought from the same suppliers, but in the future, it could be a great source of diversification since it is unclear in which areas of the world climate change will have more or less impact. Therefore, by diversifying now and having established relationships with key suppliers Diageo could be mitigating that in the future one of the suppliers is not able to cover demand.

2-How can Diageo improve the sustainability of its supply chain?

In see three additional levels of action Diageo could undertake. First, it could define standards for its suppliers on the water irrigation processes they use and only buy to the suppliers that meet the standards. Second, Diageo could make their suppliers report this data as public information. This at the same time would generate a competition among suppliers to become more sustainable in their processes. Finally, Diageo could think about vertically integrating (buy crops) to develop pilots and best practices in crop management to share after with suppliers.

Great read, Sam! It will also be interesting to see how Diageo enables better water-use techniques, such as drip irrigation. Since, ensuring continuous supply of grains is so critical to its success, I wonder if it’s time for Diageo to partner with companies such as Netafim, or Jain Irrigation, and help them scale up their water management solutions.