How is big data changing GE’s oil and gas business?

GE monitors over 800 gas turbines in 27 countries, collecting millions of hours of machine data. GE has helped its customers to avoid significant costs associated with production loss, downtime, travel, and unscheduled maintenance.

“The more we can connect, monitor and manage the world’s machines, the more insight and visibility we can give our customers to reduce unplanned downtime and increase profitability.” – Jeff Immelt, GE CEO [1]

How is GE using big data?

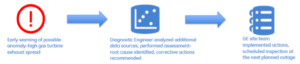

GE Oil & Gas has taken significant strides to leverage big data [2] to improve diagnostic analytics on its gas turbines [3] for application in LNG (liquefied natural gas) liquefaction. Diagnostic engineers at three strategically located monitoring centers (in Houston, Florence and Kuala Lumpur for 24/7 coverage), called iCenters, collect data from sensors on the equipment and analyze the data to provide recommendations to ensure that equipment are performing optimally for customers. Both GE and its customers have seen significant cost and production benefits from using data from sensors on capital equipment [4].

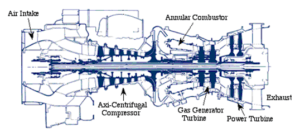

Figure: Gas turbine cross-section [4]

The most important factor to maximize profitability is uptime. GE Oil & Gas customers are willing to pay a premium to minimize downtime. Unplanned maintenance is very disruptive to business. Early diagnosis of failures is critical to avoid downtime. Reliability is a major differentiator in the LNG equipment space. Due to the high cost of capital equipment in LNG applications, it is not economical to have backup turbines. Analyzing big data helps GE Oil & Gas avoid maintenance shutdowns.

Figure: GE big data diagnostics process for the LNG liquefaction industry segment [4]

What more should GE do?

Even though GE Oil & Gas has achieved success in leveraging big data through the use of sensors to improve analytics, it has more work to do. GE must continue to improve data security, data quality, and technical expertise.

35 percent of companies state that security is a top three barrier to implementing big data initiatives [5]. By utilizing proprietary software, GE has reduced the risk of data theft, however, GE must continue to innovate on the security front. Security experts at GE should work with iCenters to understand system vulnerabilities. The budget for iCenters may be expanded to hire full-time risk analysts and managers to focus on continuous improvements on security of data. Data storage, a critical point for data leakage, should be audited periodically to ensure minimal vulnerability.

23 percent of companies state that data quality is a top three barrier to implementing big data initiatives [5]. Clear guidelines and quality metrics for data should be set for the entire supply chain [6]. By centralizing and standardizing the process for data mining and analysis, GE may ensure a level of data quality for its customers. There is an opportunity to improve GE’s predictive analytics. A report showed that most companies, including GE, focused more on using big data to monitor equipment and less on using the data to make predictions [5]. GE may employ new predictive analytics tools to better predict equipment failures. There is also an opportunity to automate some of the decision-making processes associated with big data. To improve communication with its customers, GE should consider implementing a web-based portal to relay real-time equipment failure information to customers.

57 percent of companies focus on technology enhancements without a plan to hire new employees for data efforts [7]. GE should fill talent gaps through internal training whenever possible to minimize costs. Data scientist shortages will exist in the future as the demand for big data analytics skills increase. GE should sustain a pipeline for talent in data analytics to feed its iCenters.

It is important to ensure that the savings derived from big data analytics continue to outweigh the costs associated with collecting and analyzing the data. GE’s turbines are deployed in remote locations across the world. Minimizing the need for travel (for field engineers) is important. It costs thousands of dollars to have a field engineer visit a customer site for less than a week. GE should map field engineers to particular regions in such a way as to reduce travel costs and the environmental impact of traveling.

Word count: 713

Cover image:

http://www.gereports.com/post/99494485070/everything-you-always-wanted-to-know-about-predix/

Endnotes:

[1] “GE launches Industrial Internet Solutions, Predictivity, and its KL-based Remote Monitoring and Diagnostic Center, iCenter.” GE Newsroom. General Electric, 28 Oct. 2014.

[2] Big data refers to large data sets that can be analyzed computationally to reveal patterns and trends

[3] A gas turbine is an internal combustion engine consisting of three primary parts: compressor, turbine and combustion chamber. It is used by GE customers to harvest natural gas.

[4] Monitoring & Diagnostics (M&D). General Electric, 2014.

[5] “Industrial Internet Insights Report for 2015.” GE & Accenture. 2015.

[6] Hunsicker, Rich. “Big Data, Big Data Quality Issues.” The Business Intelligence and Data Management Blog.

[7] Olavsrud, Thor. “Businesses Spending on Big Data Marketing but Not Hiring for IT.” CIO.

Interesting post! I found it interesting that security would be such a concern for big data related to LNG turbines. While of course a company should always pay mind to data security, it seems as though GE wouldn’t need to worry as much about security for this application as a healthcare initiative with PII involved. It just seems as though having performance data stolen wouldn’t be too disastrous for GE, and wouldn’t really be worth stealing to any outside parties, Of the 35% of companies that list security as a “barrier to entry,” I would imagine that a lot of those firms are dealing with more sensitive information, like health records, PII, or perhaps military/defense intel.

Security concerns for big data surprised me as well. I think in the future, more complex cyber threats could possibly be launched by individual groups or even competitors to corrupt the data being collected by GE. It is much harder to perform patchwork repairs on a cyber security system than it is to property build it from the ground up, so their concern is certainly warranted.