Going out of business! Reduce emissions by increasing diesel consumption

Yes, as counterintuitive as it seems, Cummins, one of the world’s largest heavy-duty vehicle diesel engine manufacturers, has developed engines that consume more to pollute less. In the past decade, Cummins has complicated its existence by adopting solutions to meet emissions standards such as this one that seem antithetic to this objective. To understand how Cummins got here, let’s first delve into understanding the main exhaust gases generated by diesel engines.

Exhaust emission regulations primarily focus on the reduction of Particulate Matter (PM – the black smoke which comes out of the exhaust pipe of trucks and cars) and Oxides of Nitrogen (NOx – toxic gas, main component of “smog”)1. But how do these gases generate? The process is very simple: combustion is the reaction of combustible (diesel) and oxygen. The products of this reaction are energy, heat and exhaust gases. Among the various exhaust gases produced by this reaction are PM’s and NOx’s. PM’s generate at the various stages of combustion while NOx’s generate under specific conditions of combustion.

Does a more efficient combustion allow for a reduction in emissions? Paradoxically, no. Efficient combustion occurs when combustible reacts with oxygen at higher rates, which leads to a faster increase in temperature. Higher temperatures, however, allow for an increase in NOx’s production: at higher temperatures, oxygen atoms dissociate and react with nitrogen atoms to form NOx’s2. Hence the dilemma: reducing consumption (a more efficient combustion) leads to higher emissions (in the form of NOx’s).

Cummins has addressed this conundrum by adopting Exhaust Gas Recirculation (EGR) technologies. The EGR system reduces the emission of NOx’s by basically reintroducing exhaust gases into the combustion chamber. These exhaust gases reduce oxygen intake available for combustion while also acting as heat sinks that reduce the temperature of the combustion3. This process allows for a considerable reduction of NOx’s. However, the application of EGR comes with penalties, one of which is an increase in fuel consumption4.

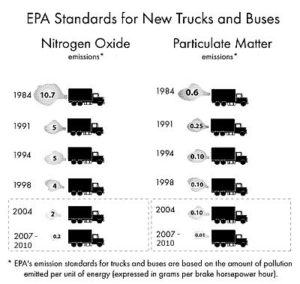

Even though EGR systems have progressively been perfected and their effect on consumption reduced, ever more stringent emissions standards have had a serious impact on the effectivity of this emission reduction system. Since EGR systems deal primarily with reduction of NOx’s, this system has had to be complemented with other components that deal primarily with PM’s and other gases. The limits on the emission of these gases in developed markets are determined by three main regulatory bodies: Environmental Protection Agency Standards (EPA), California Air Resources Board (CARB) and the European Commission (Euro). Since 2004, ever more demanding emission standards have required that heavy-duty vehicles reduce both NOx and PM emissions by nearly 90%5.

These standards have forced Cummins to constantly focus on refining EGR systems and develop novel components. These efforts have translated in not only less performing and more expensive engines, but also in more intricate designs that complicate maintenance processes. Where previous engine generations allowed personnel with basic maintenance skills and knowledge to solve a wide range of issues, newer engine generations require specialized – and expensive – maintenance.

For the past century, heavy-duty vehicles have been powered almost exclusively by diesel-powered engines. However, given the increasing difficulty to meet emission standards and no apparent major breakthroughs in internal-combustion engine technology7, the search for new type of engines has gained traction over the past decade. One such example are battery-powered engines. The use of these engines had been limited by battery capacity. Recent advances in battery technology have not only increased electric vehicle’s range8, but also allowed cars powered by electric engines to perform almost as well as those powered by internal combustion engines. Moreover, these engines are very convenient to use: their maintenance is simple and the battery can be charged at home – eliminating the inconvenience of having to drive to the gas station9.

These fundamental changes question the viability of Cummins’ business model: three fifths of Cummins’ engine categories are diesel engines. Engines and engine component sales account for 64% of Cummins’ 2015 sales10. Unless Cummins comes up with a radical proposal for internal combustion engines that allows it to comply with emissions standards and make maintenance easier for its customers, it will have to shift to new technologies. Cummins either evolves or it will go out of business.

702 words

Sources

1Cummins Emissions Solutions, Emissions Fundamentals, http://www.cumminsemissionsolutions.com/Emissions_Fundamentals, accessed November 2016

2Deepak Agarwal, Shrawan Kumar Singh, Avimash Kumar Agarwal, “Effects of Exhaust Gas Recirculation (EGR) on Performance, Emissions, Deposits and Durability of a Constant Speed Compression Ignition Engine”, Department of Mechanical Engineering, Indian Institute of Technology , January 2011

3Cummins Turbo Diesel Resource, Cummins Emissions Equipment Overview, http://www.cumminshub.com/emissions.html, accessed November 2016

4G.H. Abd-Alla, ”Using Exhaust Gas Recirculation in Internal Combustion Engines: a Review”, Al-Ain Technical School, April 2001

5Cummins Emissions Solutions, Worldwide Emissions Regulations, http://www.cumminsemissionsolutions.com/Worldwide_Emissions_Regulations, accessed November 2016

6Environmental Protection Agency, Diesel Exhaust: Basic Information, https://www3.epa.gov/region1/eco/diesel/basic_info.html, accessed November 2016

7”The Great Powertrain Race”. The Economist, (April 2013)

8”A Plug for the Battery”. The Economist, (January 2016)

9”Why the Low Oil Price Will Not Harm Sales of Electric Cars.” The Economist, February 24th, 2015. http://www.economist.com/blogs/economist-explains/2015/02/economist-explains-21?zid=291&ah=906e69ad01d2ee51960100b7fa502595

10Cummins. 2015 Annual Report. Washington D.C: Cummins, 2002

The above examination of Cummins’ business model brings up a very important and often overlooked point on the difference between climate change and pollution. When we think about climate, we generally focus on the impact that carbon dioxide and methane emissions will have on global temperatures and weather patterns, but we forget that the combustion of fossil fuels has other negative implications, including air pollution. Companies like Cummins must deal with both sides of this issue and may find it difficult to adapt. I agree with the author’s conclusion that companies like Cummins may ultimately find themselves in the position of not longer being relevant. Utilities that own coal fired power plants know this challenge intimately as they have been forced to lower their NOx emissions over the past few decades while simultaneously reducing their carbon emissions.

NJ234, thanks for this interesting post. At least ostensibly, it appears that Cummins’ business model may be significantly challenged in the near term as it attempts to adapt to an evolving regulatory and technological environment that may render its current diesel engine technology obsolete. Outside of this specific example, I think there may be a broader lesson. As a manager of a business crafting it strategy, it’s important to not only consider today’s regulatory / technological environment but also the broader context of how the industry is likely to evolve over the medium to long-term. This type of thinking helps ensure your company doesn’t just focus on “band-aid” products or technologies that quickly become irrelevant. It seems like Cummins focused on making some incremental improvements to engine technology when a more thoughtful examination of the broader threat posed by climate change and greenhouse gases (not just the localized pollutants that EGR appears to address) would have made it clear that a real step-change was needed.

NJ234, thank you for the interesting post. I think the situation faced by Cummins is a common one; sustainability almost always seems to be diametrically opposed to the goals of businesses. By addressing climate change, many businesses feel that they have to compromise the value they provide to stakeholders, be it the product experience for customers, profitability for shareholders, or policies for employees. High-emission industries such as transportation face particularly high tradeoffs, as their core value proposition is often not environmentally friendly, and available alternatives are too often inferior or prohibitively expensive. I’d be curious to know how customers have reacted to the newer engines, as the costs of Cummins’ adaptations are being passed on in the former of higher priced engines and increased fuel costs. That being said, customers may have no other choice, assuming that Cummins’ competitors are subject to the same emissions regulations and have innovated similarly. Until we find a way for the environment to win in the long-term without every other stakeholder losing in the short-term, these frictions will continue.

Very interesting post! What jumps out to me is that emissions standards have essentially forced Cummins to innovate, which is a positive thing for the environment, but also threatens the very existence of the company. It highlights the difficult tension between regulations to address climate change and the burden that those regulations place on companies that are vital parts of the economy. Generally speaking, I perceive the “creative destruction” of obsolete organizations to be a positive thing for the economy in the long term, but in cases like this where obsolescence may be “forced” by regulation, it makes me wonder if regulators and organizations can work better together, such that a company like Cummins is able to innovate for compliance with emissions standards, but within limits that are feasible and do not spell the company’s demise.