From Paper to Parametric Vectors: Gehry’s Transformation of Architectural Modeling

“I learned most building construction wastes a lot of materials and time due to poor planning. Frank has designed special software to assist in his architecture, so he's very efficient.” –Mark Zuckerberg

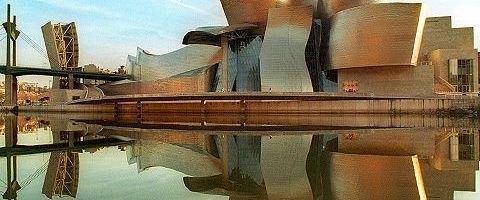

LA’s Disney Concert Hall. The Barcelona Fish. You’ve probably heard of the legendary architect behind these creations, Frank Gehry, but did you know that his firm spurred a digital transformation within the world of architecture?

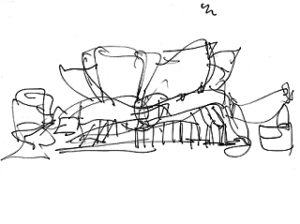

Gehry founded his architectural practice, Gehry Partners, in 1962. By the 1980’s, he had defined a new architectural style characterized by playful geometric complexity and was infamous for creating his forms through freehanded sketches followed by “tearing scraps of paper, gluing and taping them together, crinkling cardboard, and adding apples and Perrier bottles”[i] to create crude physical models. His team was then challenged to construct these fantastical shapes in a structurally sound and cost-effective manner, necessitating extremely precise models.

While designing a 50 meter undulating fish sculpture for Barcelona’s 1992 Olympics, Gehry realized that the available 2D programs were unable to model the sculpture’s curvature. So, a Gehry employee turned to CATIA, a C++ software package developed by an aerospace manufacturer.[ii] The same program that was used to design the Mirage fighter jet was now being used to design a fish sculpture.

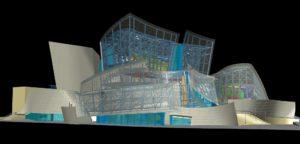

CATIA fundamentally redefined architectural digital modeling. Rather than using 2D drawings, CATIA “described digital models using parametric Bézier curves (or vectors) and 3D surface algorithms…[defining] a set of control points and the mathematical functions, or surfaces, that stretch between them.”[iii] By offering increased flexibility, the program minimized time and effort required for design changes, resulting in increased collaboration and understanding between the main designer (the architect) and other engineering-based collaborators.[iv] Utilizing this software, the Barcelona Fish was built in six months within budget.

![A 3D Bézier surface with control points [8]](https://d3.harvard.edu/platform-rctom/wp-content/uploads/sites/4/2016/11/CATIA-Source-1-300x242.png)

Previously, architecture firms (with minimal collaboration) delivered 2D drawings to a contractor, who then then created its own set of drawings/models that had to be approved by the architect before moving to fabrication. However, with CATIA, contractors were able to (i) become involved earlier in the design process and (ii) refer directly to Gehry’s 3D digital models, saving time, money, and making the entire design chain more efficient.

To capitalize on this innovation, Gehry Technologies (GT) was founded in 2002 to facilitate visionary designs while keeping cost and schedule in line for clients.[v] Supplementing his architectural firm with a technology/software firm fundamentally changed Gehry’s value proposition to clients: working together, the companies were now responsible for the entire digital model (materials, specifications, and costs), removing this step from the contractor’s role and “bring[ing] fabrication expertise forward into design.”[vi] GT continued to innovate through a number of avenues, including:

Customization: GT addressed an untapped market potential by creating Digital Project, a CATIA-based software designed specifically for architecture firms that provided design support for construction scheduling and plumbing.[vii]

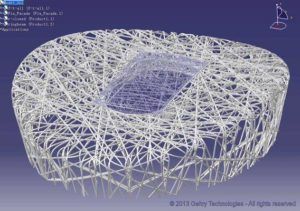

Project Delivery Service: GT provided consulting services to other firms, transforming designs into structurally-sound buildings (and saving ~10% of the building’s cost[viii]). As a result, GT advised on several projects (like the 2008 Bird’s Nest Stadium) which that provided insight into how other design firms operated.

Several future opportunities exist for this service: GT could potentially expand its consulting operations to applications necessitating accurate measurements and efficient space utilization, such as dam designs or electric grids.

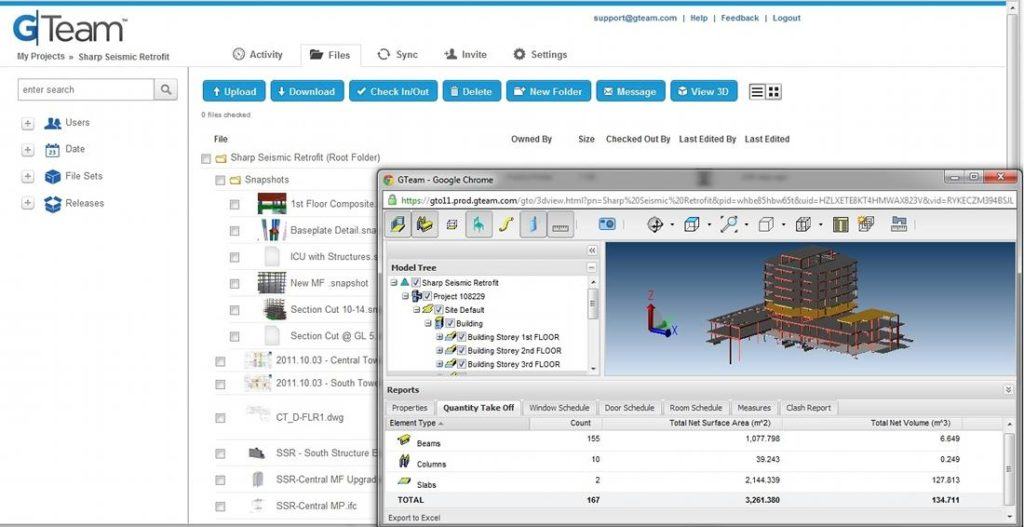

Collaboration: GT developed GTeam, a project-based collaboration platform enabling players in the design process to share and consolidate data. GTeam incorporated elements of social media: “like a mix of GitHub, Google Docs, and Facebook, but for design and construction, GTeam allows collaborators to simultaneously edit different models within a project.”[ix] The implications of this platform were immense—never before had the full design chain been digitally integrated into one dynamic system. GT also addressed a major industry concern: “given the financial and legal structures that conventionally discourage architects, engineers, and contractors from sharing information so freely, the software also logs each move for legal record-keeping.”[x] As a result, subcontractors and fabricators were able to work with architects and contractors during the design phase, which reduced errors, minimized redundant communication, and enabled the design team to incorporate feedback from various trade experts and specialists.[xi] Increased collaboration led to the completion of groundbreaking projects on time, under budget, and with fewer change orders.[xii]

GT disrupted the architectural industry by creating innovative software that made building designs more efficient, accurate, and cost effective. By shortening the design chain and providing a collaboration platform for engineers, architects, and contractors, GT facilitated innovation and changed the way that architecture firms provide value not just to customers, but to competing firms and contractors.

(Word count: 792)

Text Sources

[i] https://priceonomics.com/the-software-behind-frank-gehrys-geometrically/

[ii] https://priceonomics.com/the-software-behind-frank-gehrys-geometrically/

[iii] https://priceonomics.com/the-software-behind-frank-gehrys-geometrically/

[iv] http://www.jitbm.com/JITBM%2016th%20volume/4%20Digital%20Innovation.pdf

[v] https://www.trimble.com/news/release.aspx?id=090814a

[vi] http://www.gehrytechnologies.com/en/

[vii] https://priceonomics.com/the-software-behind-frank-gehrys-geometrically/

[viii] https://priceonomics.com/the-software-behind-frank-gehrys-geometrically/

[ix] https://priceonomics.com/the-software-behind-frank-gehrys-geometrically/

[x] https://priceonomics.com/the-software-behind-frank-gehrys-geometrically/

[xi] http://www.sciencedirect.com/science/article/pii/S2095263514000429

[xii] https://www.trimble.com/news/release.aspx?id=090814a

Image Sources:

[1] Cover Photo: https://www.pinterest.com/maxamen/deconstructivist-architecture/

[2] http://www.gehrytechnologies.com/en/main/about/

[3] https://priceonomics.com/the-software-behind-frank-gehrys-geometrically/

[4] http://www.mdgarcia.com/2010/03/frank-gehry-design-process.html

[5] https://priceonomics.com/the-software-behind-frank-gehrys-geometrically/

[6] Ibid.

[7] Ibid.

[8] Ibid.

[9] Ibid.

Thanks for the architecture article (I enjoy the subject). While Gehry Technologies pioneered the use of collaborative software in the architecture and structural engineering space, it could really be applied in any design capacity to streamline the design process. The ability to design a physical product in a team must require a great deal of work on many separate aspects of the product design. I would imagine that sometimes the component that one designer is creating could be incompatible with an adjacent component if the two designers are not communicating. I think having everyone linked to the same “master” design file such as the one that GT is using with their software program would really eliminate this sort of miscommunication and wasted effort.

Ariana, you forgot to mention the Art Gallery of Ontario! Just kidding (though, it is another beautiful design by Gehry). I’ve often marvelled at Gehry’s architecture around the world and wondered how he managed to create such intricate and unusual designs. It’s fascinating that his team were the first to leverage this tool and that it enabled them to build the Barcelona fish in just 6 months. As I was reading more about the topic, I noticed that Gehry just made the program available to the public within the last few years. It’s a great thing he did because now the world will benefit from other architects who can pair their creativity with the cost-savings capabilities of this incredible tool. Hopefully, as more architects adopt technologies like these, we will see much more variation and originality in buildings constructed.

I am extremely interested in how architecture, construction and infrastructure design are being shaped by technological innovation, so very much enjoyed reading your post, Ariana.

A lot of efficiency, time, money and productivity is lost in the communication between architects and construction companies. 80% of large scale construction projects go over budget and on average take 20% longer than forecasted. Employing 3D visualisation tools like CATIA in architecture therefore has huge benefits along the entire supply chain.

In my research of how architects and construction industries can use technology more effectively, I came across the concept of Building Information Modelling (BIM) very frequently. BIM is a tool that allows the effective coordination and communication between different participants in the lifecycle of a design and construction project by capturing not only 3D models, but also relevant data for the construction process, progress updates and other information in one easily processable platform that can be shared between architects, developers, raw material suppliers and other stakeholders.

Autodesk’s website is extremely interesting on this topic: http://www.autodesk.com/solutions/bim/hub/bim-101#related-bim-101-video

Very interesting article, Ariana! For Japan’s construction for the Olympic stadium, the committee had to change the design this year because the original design voted for actually costed a lot more than what was anticipated at the time of the design.

http://www.forbes.com/sites/keithflamer/2016/02/12/the-ugly-dust-up-over-tokyos-2020-olympic-stadium/#6d490bbb7117

I like your suggestion on how the industry could try to incorporate raw costs into the designing technologies so clients could compare all aspects of the potential design when making a decision.

Interesting article with some great applications of the topics we have been discussing in class. I think I was struck most the reduction in variability throughout the architectural ‘supply chain’ through greater information sharing on the CATIA platform. Allowing the early involvement of contractors in the design process and access to a common base model is a fascinating use of digital technology to reduce variability in an operations process, and I agree with Tom that the applications of CATIA to other industries heavily reliant on complex designs is significant. I also liked your recommendation to expand the platform to include raw material sourcing as a way of further increasing the flow of information across the platform. I think that other areas of improvement could include a meeting/facetime platform as well in order to offer contractors and designers the opportunity to engage in real-time collaboration through the same portal.