Evolution of the Smart Pig

Digital technology innovation and application changes the name of the game in pipeline inspection and quality assurance.

Even amongst industry experts, the origin of the term is still debated. Engineers will reason that “pig” is simply the acronym for “pipeline inspection gauge,” yet most operators will explain that the tools are named for the distinct squealing sound they make as they pass through piping. Regardless, the benefits of routine pipeline pigging is something that everyone can agree upon.

From a business model standpoint, leading pipeline service specialists such as T.D. Williamson, Inc., ROSEN Group, and GE Oil and Gas (PII Pipeline Solutions) historically captured value by providing pipeline owners and operators with cleaning and maintenance solutions for otherwise inaccessible pipeline systems.[1] Although the pigging industry was founded upon relatively primitive technologies, the efficient adoption and application of digital innovation has allowed these service companies to grow their capabilities and provide an entirely new spectrum of value associated with proactive, preemptive hazard mitigation.

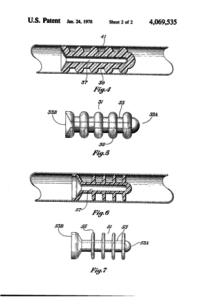

The earliest generation of pigs were strictly mechanical devices used to swab the interior walls of a pipeline system. The concept wasn’t exactly revolutionary, but basic pig design has, “come a long way from bails of rags wrapped with barbed wire.” [2] Today mechanical pigs are commonly bullet-shaped foam or rubber devices which when propelled by the normal operating flow of a pipeline system can effectively dislodge paraffin and other debris from the interior pipeline walls. Though the primary purpose was always cleaning, pipeline operators also took an interest in analyzing the product that the pigs removed. In fact, version 2.0 of the pipeline pig focused entirely on recovering internal system information. [3, 4]

The gauge plate pig offered operators a, “fast, cost-effective way to determine whether there was an obstruction or pipe diameter reduction in their pipeline.” [5] This technology represented a pivotal moment for the pipeline industry, but the data acquired by running a gauge pig was still largely incomplete as there was no way to identify the location or quantity of obstructions that the pig encountered.

In the early days of pigging, if a pipeline developed a leak or rupture, the only acceptable response was to shut down the line and begin searching for a puddle. Assuming you can find some visible representation of the product loss, you still have to dig to discover the extent of the damage, and only then begin to plan repairs accordingly. The industry measures the associated downtime with a monetary utilization metric known as Lost Product Opportunity (LPO).

Introduction of Digital Technologies

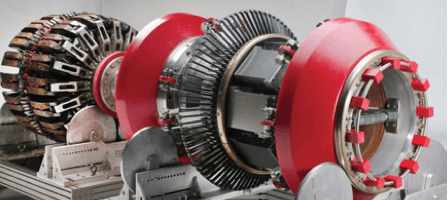

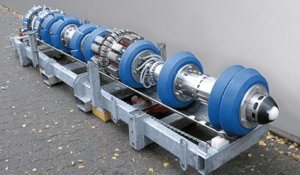

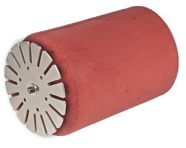

Although the pigging companies retained their high-level value proposition (specialized pipeline maintenance), the digital transformation of the industry completely redefined the methods by which value was captured. The maintenance service operating model has transitioned away from uninformed routine upkeep to focus on system integrity, inspection, and informed preventative maintenance. The transition hinged upon the ability to rapidly collect and store real-time, digitized, pipeline data while the pig travels through the system. The swabs now look more like satellites, and acronyms such as MFL, ILI, and GEO represent the technical enhancements that ride along with the “smart pig” tools. [6] Some key technologies include:

Although the pigging companies retained their high-level value proposition (specialized pipeline maintenance), the digital transformation of the industry completely redefined the methods by which value was captured. The maintenance service operating model has transitioned away from uninformed routine upkeep to focus on system integrity, inspection, and informed preventative maintenance. The transition hinged upon the ability to rapidly collect and store real-time, digitized, pipeline data while the pig travels through the system. The swabs now look more like satellites, and acronyms such as MFL, ILI, and GEO represent the technical enhancements that ride along with the “smart pig” tools. [6] Some key technologies include:

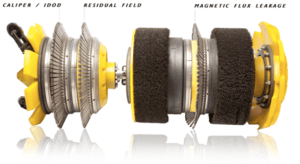

Magnetic Flux Leakage (MFL): Two or more magnets are placed on the tool in linear alignment and create a field that interacts with the pipe wall. Associated instruments on the tool can measure the strength of the field and subsequently identify wall thickness anomalies. [7]

Magnetic Flux Leakage (MFL): Two or more magnets are placed on the tool in linear alignment and create a field that interacts with the pipe wall. Associated instruments on the tool can measure the strength of the field and subsequently identify wall thickness anomalies. [7]

Electromagnetic Acoustic Transduction (EMAT): Ultrasonic waves are generated inside the pipe wall itself, and a sensor analyzes frequency to locate material deformations. [8]

Internal Navigation System / Global Positioning System (INS/GPS): Satellite communication allows this device to track the precise latitude, longitude, and elevation of the pipeline system. [9]

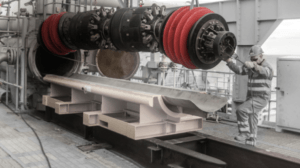

Typically, several tools are introduced into the line in tandem, and the entire train collects data simultaneously. The value of such an inspection system is magnified by the ability to cross reference, compile, and analyze the data comparatively. Suddenly, a wall thickness anomaly can be identified, immediately located, and addressed without ever impacting the normal operating conditions on the system. Potential leaks are proactively mitigated with a temporary repair sleeve until a permanent restoration can take place during the next scheduled system outage.

Looking Forward

In-line inspection and the access to system integrity information helps maximize process utilization by increasing the credibility of non-destructive testing. Pipeline regulatory and safety agencies have adopted smart tool inspection as an acceptable mechanism for verifying the integrity of a pipeline system. Previously, a full hydrostatic test was required to keep the system qualified for service.

While the pigging industry has made massive strides in quality inspection and assurance technology, it still faces several challenges. The tools are not infallible and still experience limitations of detection when defects are small enough. [1] Additionally, inspection equipment will occasionally get stuck inside a pipeline, leading to extremely costly extraction and repairs.

(799 words)

References

[1] Newman, N. (2015). ILI offers a technology that will continue to advance. Pipeline & Gas Journal, 242(11), 82-82,84. Retrieved from http://search.proquest.com.ezp-prod1.hul.harvard.edu/docview/1733616396?accountid=11311

[2] Roberts R. Pipeline Pigging & Cleaning What Do We Really Know About It?. Pipeline & Gas Journal [serial online]. August 2009;236(8):57-63. Available from: Business Source Complete, Ipswich, MA. Accessed November 17, 2016.

[3] Cato, B. D. (1978). U.S. Patent No. 4,069,535. Washington, DC: U.S. Patent and Trademark Office.

[4] T.D. Williamson Company, “Pipeline Cleaning Pigs,” http://www.tdwilliamson.com/solutions /pipeline-pigging/pipeline-pigs/cleaning-pigs, accessed November 2016.

[5] T.D. Williamson Company, “Gauging Pigs,” http://www.tdwilliamson.com/solutions/pipeline-pigging/pipeline-pigs/gauging-pigs, accessed November 2016.

[6] Clark, B. (2005). Pigging continues on strong course worldwide. Pipeline & Gas Journal, 232(8), 26-32,34-36. Retrieved from http://search.proquest.com.ezp-prod1.hul.harvard.edu/docview/197435308?accountid=11311

[7] Dual field MFL pig may provide best of both worlds. (2005). Pipeline & Gas Journal,232(10), 54-56. Retrieved from http://search.proquest.com.ezp-prod1.hul.harvard.edu/docview/197457765?accountid=11311

[8] Klann, M., & Beuker, T. (2006, September). Pipeline inspection with the high resolution EMAT ILI-tool: report on field experience. In Proc. IPC

[9] Smith, J. W., & Hay, B. R. (2000). U.S. Patent No. 6,023,986. Washington, DC: U.S. Patent and Trademark Office.

Picture Citations

[a] Rosen Group, “Cocombo MFL-A/UTWW Service,” http://www.rosen-group.com/global/solutions/services/service/rocombo-mfl-a_utwm.html, accessed November 2016.

[b] Enduro, “MFL-dfl,” http://www.enduropls.com/products/inspection/dfl.html, accessed November 2016.

[c] T.D. Williamson Company, “Non-Intrusive Inline Isolation,” http://www.tdwilliamson.com/, accessed November 2016.

[d] Inspectioneering, “The Current State of Pipeline Integrity Management,” https://inspectioneering.com/journal/2014-10-22/4209/the-current-state-of-pipeline-, accessed November 2016.

Will, first, thanks for introducing “pigging industry” into my lexicon. Really interesting post–a great example of how digitization is remaking even the most unexpected products. I am curious how widely adopted these new pigs are in the industry? Has the prolonged drop in oil prices hurt the spread of this kind of technology? Have companies been forced to build out their analytics and data processing teams to keep up with the new influx of data from devices like these (and other previously “dumb” devices) that are now spitting out reams of data?

Good post Will on a very large issue in the pipeline industry. In my time at Alyeska Pipeline, one issue that we struggled to address, even with improvements in pigging technology, is dead end piping. These are areas of the pipeline where pigs cannot travel, and areas that are very prone to corrosion or debris buildup. Several technologies have evolved over the past several years, such as ultrasonic testing, though none as accurate as these advanced pigs. I expect this will be the next big advance in pipeline monitoring.

Great post. I’d be interested to know whether the industry is combining pigging data with weather and topographical data to see whether there are correlations so that pipeline companies might better understand where to focus maintenance efforts in the future. Are these same companies (or the oil companies) developing smart cleaning or repair technology that might be able to do maintenance inside the pipeline once problem areas are identified?