Disruption in the automotive business: how distributed innovation can change a 100-year-old industry?

Local Motors Inc. is using open innovation to efficiently change the product development process of a typical car manufacturing company, quickly delivering low-cost and creative designs to customers.

CONFIDENTIAL. I saw that word in every single technical drawing during my 4 years working for Toyota. After co-leading the product development process of Toyota’s worldwide best-selling truck (see Exhibit 1), I wondered if it was possible to develop vehicles without being so “strictly confidential”. Well… the answer is YES!

Founded in 2007 by Jay Rogers (HBS 2007) with a belief in open collaboration and co-creation, Local Motors Inc. (LM) began low volume vehicle manufacturing of open-source designs using multiple micro-factories. [1] LM stands out for combining new innovative technologies to launch Olli, the first co-created, self-driving, electric and 3D printed shuttle (see Exhibit 2).

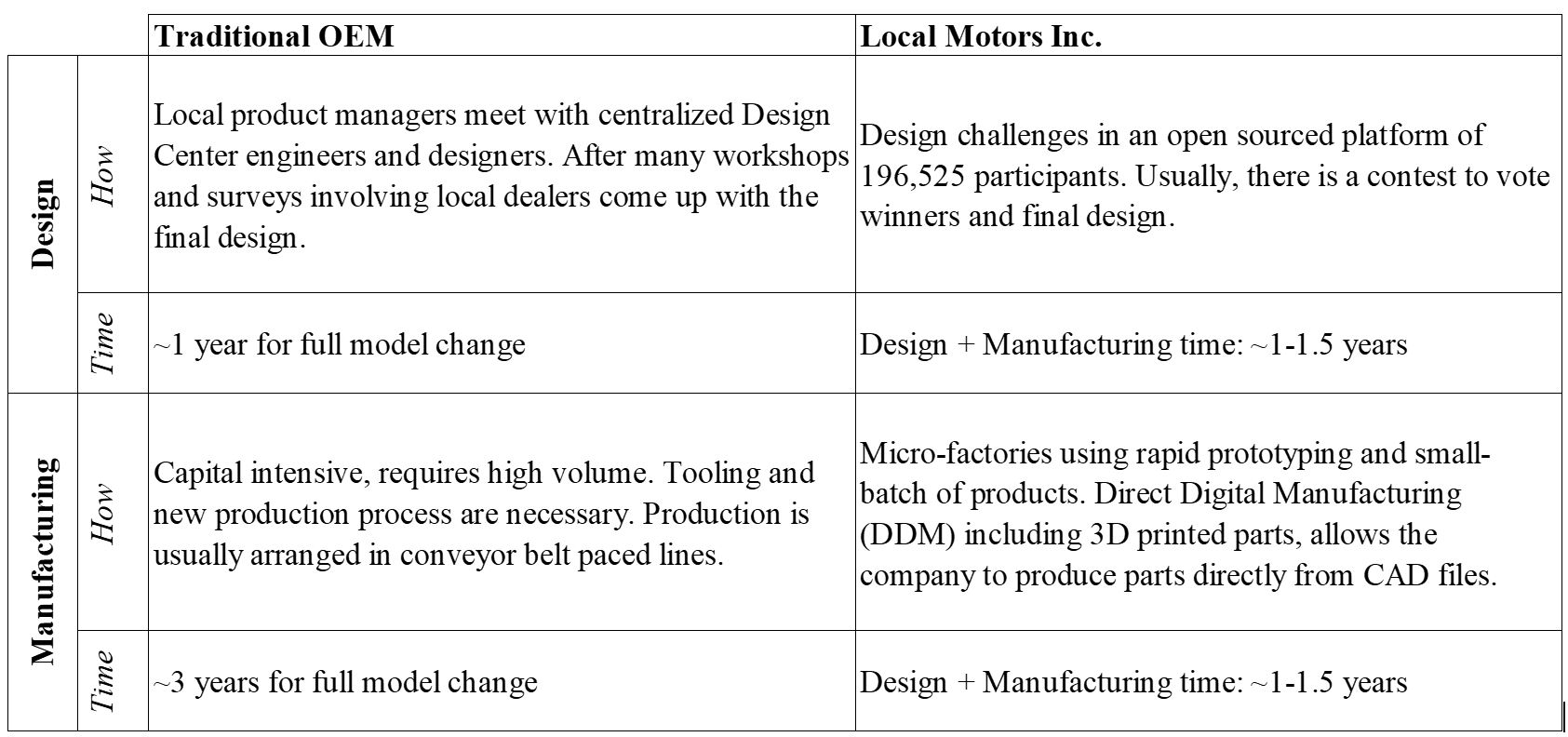

Applying crowdsourcing innovation, can dramatically reduce costs and lead time of a vehicle development process, while sourcing the company with creative ideas. The design process of a new vehicle in a typical manufacturing company lasts at least 1 year and costs millions of dollars utilizing valuable resources such as highly skilled designers and engineers At LM things are a little bit different (see Exhibit 3). Olli’s current design was conceived by a 24-year-old Colombian after winning the Urban Mobility Challenge: Berlin 2030. He was paid $28,000 (roughly 2 monthly salaries of senior engineers) for winning the challenge and is expected to obtain royalties when LM begins commercializing the shuttle. [2]

In addition, it is important to discuss how the company is deploying distributed innovation. LM launches challenges and hosts an open innovation crowd-powered SaaS platform that community members can use to co-create products such as Olli. But it is not only about cars, LM developed the Launch Forth platform, which works with big-name manufacturers such as GE and the Airbus to help companies innovate and manufacture products faster.[3]

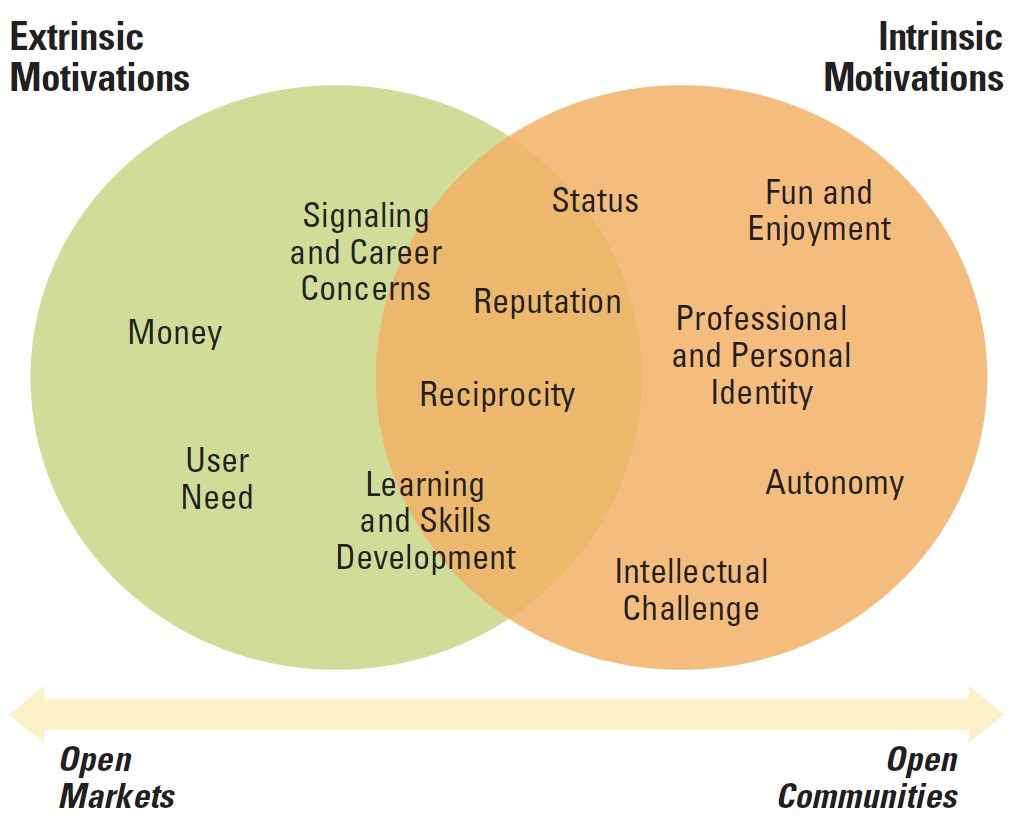

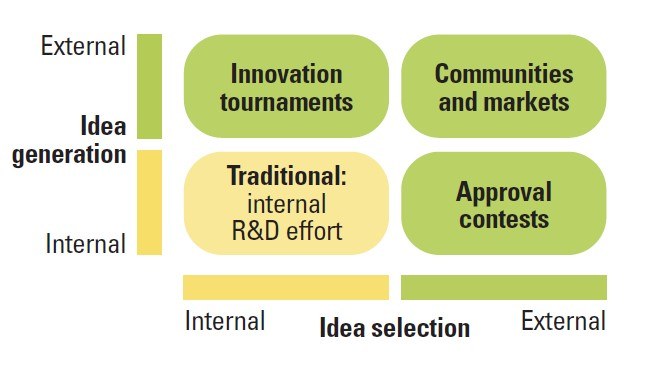

In this process, it is critical for the company to get motivated talent. Participation can be due to either extrinsic or intrinsic factors. Extrinsic are related to rewards or just specific individual needs to perform the task. Intrinsic values are more emotional and comes with enjoyment, having fun and the social benefits of being part of a community. [4] LM is hugely leveraging the external factors through monetary prizes and royalties to further motivate its community (See Exhibit 4). Furthermore, it is relevant to note that LM not only outsource the idea-generation process which ends up in the vehicle design, but also the empowers the participants in the idea-selection process to vote in challenges and design contests (see Exhibit 5).[5]

After analyzing the importance of open innovation in LM and how the company is using this megatrend, I think there is still room from improvement. My recommendation for Jay Rogers’ company is that it appeal more to intrinsic values to motivate people and foster knowledge sharing.

LM seems to be focusing too much on economic rewards. Trying to foment joy and a stronger sense of identity among the community members might trigger intrinsic motivation within participants and thus, less need for economic incentives. Optimizing on only one dimension might have the effect of limiting participation.[6]

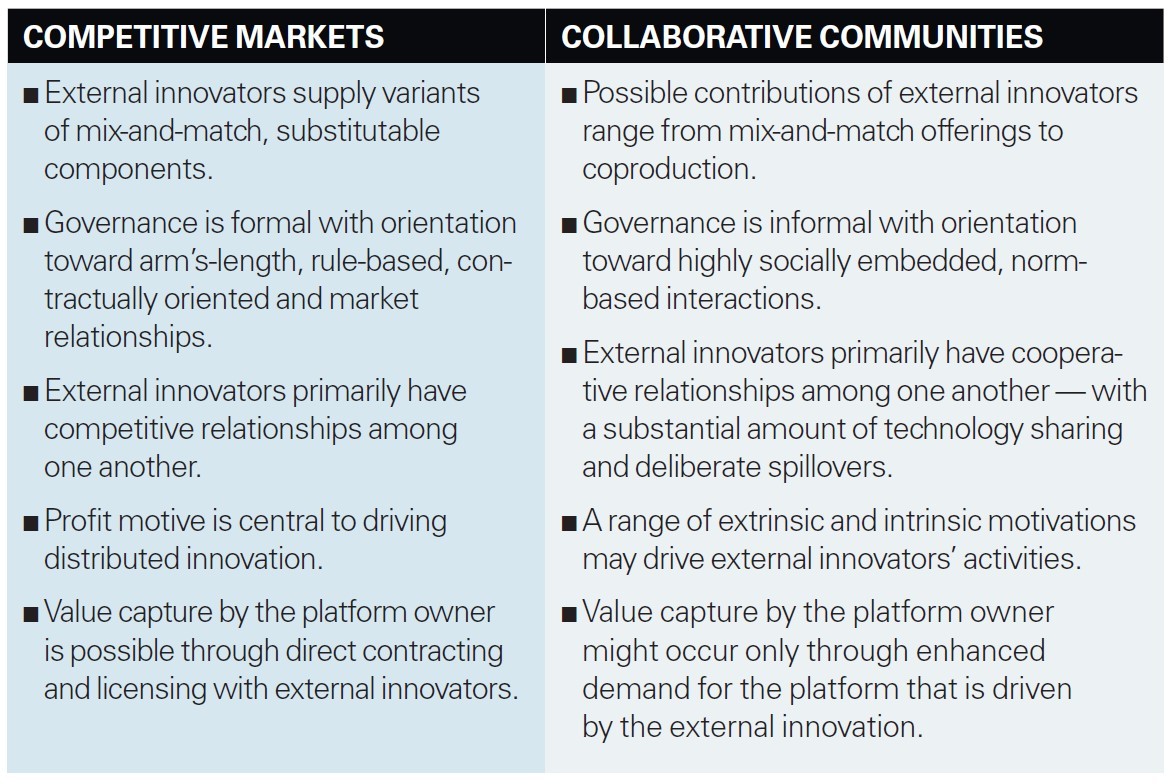

The second advice relies on that there are two ways to organize external innovation: collaborative community or competitive market (see Exhibit 6). Currently LM is in the competitive market group. Participants have economic incentives to differentiate, to search for novel solutions and to protect rather than share knowledge.[7] I believe LM could take more advantage of the crowd-source innovation if it promotes mechanisms to further increase knowledge sharing within participants.

To sum up, LM is changing the paradigm of the confidentiality in the vehicles development processes. It is leveraging its community-based innovation platform to deliver quickly, cost efficient and creative vehicles.

However, I find myself struggling with the following questions:

- Should LM let community members vote in the design decision or just outsource the design development and decide by itself which product to launch?

- Should it give more even more autonomy to participants, allowing them to sell directly products to customers?

(798 words)

Exhibit 1. Toyota Hilux 2018.

Source: https://autoblog.com.ar/2018/08/21/lanzamiento-toyota-hilux-2019/

Exhibit 2. Local Motors Olli.

Source: https://launchforth.io/localmotors/olli-self-driving-cognitive-electric-shuttle/latest/

Exhibit 3. Product Development process comparisons between OEMs and Local Motors Inc.

Source: Essay writer.

Exhibit 4. Motivation drivers for external innovators.

Source: K. Boudreau and K. Lakhani. How to manage outside innovation. MIT Sloan Management Review 50, no. 4 (Summer 2009): p.71.

Exhibit 5. Different Innovation approaches.

Source: A. King and K. Lakhani. Using open innovation to identify the best ideas. MIT Sloan Management Review 55, no. 1 (Fall 2013): p.43.

Source: A. King and K. Lakhani. Using open innovation to identify the best ideas. MIT Sloan Management Review 55, no. 1 (Fall 2013): p.43.

Exhibit 6. Differences between ways to organize external innovation.

Source: K. Boudreau and K. Lakhani. How to manage outside innovation. MIT Sloan Management Review 50, no. 4 (Summer 2009): p.74.

Endnotes

[1] Source [Acrofan, “Local Motors Inc. announces partnership with Robotic Research, LLC”], via Factiva, accessed [November 2018].

[2] Alina Selyukh, “A 24-Year-Old Designed A Self-Driving Minibus; Maker Built It In Weeks”, National Public Radio, June 29, 2016, [URL], accessed November 2018.

[3] Source [Hayley Ringle, “EXCLUSIVE: Local Motors launches new division to help big-name manufacturers innovate faster”, Phoenix Business Journal, September 13, 2016], via Factiva, accessed [November 2018].

[4] K. Lakhani and J. Panetta. The principles of distributed innovation. Innovations: Technology, Governance, Globalization 2, no. 3 (Summer 2007): p. 103.

[5] A. King and K. Lakhani. Using open innovation to identify the best ideas. MIT Sloan Management Review 55, no. 1 (Fall 2013): p.43-45.

[6] K. Lakhani and J. Panetta. The principles of distributed innovation. Innovations: Technology, Governance, Globalization 2, no. 3 (Summer 2007): p. 104.

[7] K. Boudreau and K. Lakhani. How to manage outside innovation. MIT Sloan Management Review 50, no. 4 (Summer 2009): p.71.

Very cool post! Do you think that more manufacturers will shift to an open innovation process? What do you see as being the biggest barrier to widespread adoption? My guess is that companies are attracted to the open innovation model because of how much more rapidly they could conceive of and develop product, but does this get in the way of competitive advantage and profitability?

Very interesting article! I am concerned that this open innovation model won’t take-off in the auto industry because it interferes with the market feedback mechanisms of price and profit. By effectively outsourcing design, there is no doubt that Local Motors is able to drastically reduce their design costs for a vehicle. But, this comes at the expense of potentially failing to meet a need that is being signaled by the market. If the collective wisdom of the participating community produces a vehicle that the market doesn’t want or need, then Local Motors has a low cost product that will go for a very low price indeed. I’d be interested to see what kind of controls they put in place to ensure that they are producing vehicles that fit a need in the market!

Loved your piece – it really changed the way I viewed the product development process of automobile manufacturers. I think Local Motors are brave in completely transforming the development process of automobiles by using crowdsourcing. Moreover, they seem to be doing an excellent job given the design of Olli, which delivers low-cost and creative designs.

Given the enormous pressure the automotive manufacturing industry is facing, driven by strict CO2 emission regulations, shifts toward hybrid/electric vehicles and faster model cycles, automobile manufacturers must innovative to remain in the game. The industry hence must reinvent itself, and I think getting insights from outside parties that are not as stuck in the current way of operating, might be a great way to fuel innovation with creative and outside-the-box ideas.

Regarding the best way to organize the external innovation, my pick is the collaborative community approach. It enables participants to work together, questioning and challenging the ideas of others, and build upon the ideas of others, which I believe leads to more innovative and disruptive ideas in the end.

The more freedom you give participants, the more outside-the-box thinking and crazy ideas will be unearthed – and these ideas are key to disrupt the industry. Therefore, I would invite participants to take an active part in the process by voting on design process steps. However, I still believe it is key for Local Motors to provider a structure for the discussions, and not allow participants to sell products directly to consumers

Wow, this is a cool post! I think this form of open innovation sounds like a win-win for consumers and producers alike. Producers get to minimize their costs and shorten their design-to-production timelines, getting in line with trends and capitalizing on those trends in the form of increased sales. Consumers get a chance to shape their own experience and bring their sizable talents to bare. I would posit to you that LM is already capitalizing on the intrinsic values of their designers – these are self selecting people with skills who are inspired by the challenge and likely find a lot of fun in participating in competitions regardless of the political motivators. Some questions I have going forward lie in the command and control and compensation arenas of the open innovation process. Does Toyota, LM, etc relinquish command and control of the design processes to the consumer and risk their brand identity to the whims of the fickle internet denizens or do they select designs that they believe fit with who they are as companies and who they cater to? Also, since the design is one of the most important parts of a consumer good such as vehicles, will these companies feel pressure from the design community to pay out royalties that ultimately total more than the costs of their traditional engineer-based designed process?

I see two challenges with open innovation like local motors has adopted in the automotive industry.

1) The automotive industry is filled with historic knowledge that many don’t have access to in a class room. While open innovation can rapidly lead to great new ideas. How do we incorporate previous findings over the past 100+ years? Can automotive technical experts act as the gate keepers at the end of this rapid innovation?

2) How do we mitigate risk around safety? Vehicles are expected to meet safety standards. How can we ensure our open source design progresses towards the highest standards of safety? How do we communicate crash safety results to the open-source team?

Maybe some of these risks are eliminated by relying on open innovation earlier in the development cycle and blending more traditional development cycle processes closer to product.

Hi Joaquin, thanks for sharing this interesting information! It’s very cool what Local Motors is doing to crowd-source innovation. I think one component of what allows this model to work is the fact that they are giving royalties to people / teams that come up with winning designs, which engenders a sense of ownership in the innovation process and creates a financial incentive for people to undertake this difficult task. However, this is only possible because the company’s products are meant to be small-scale, low volume products. If a company like Toyota were to employ the same approach, those designs might be used in a very large number of vehicles. In that case, it may be more expensive to pay a healthy royalty than to just employ teams of engineers (who make fixed salaries) to generate designs in-house

In terms of your 2nd question about allowing participants to sell directly to consumers, I think there are a couple of barriers. One is the fact that many of the participants may not have the capital to invest in manufacturing facilities, which tend to be expensive. Moreover, I think you run the risk of having products being sold to consumers that don’t pass stringent quality and safety standards. These are not your typical consumer product – they are large machines that need to operate on the roads, with potential to cause accidents and severe injury if they’re not safe. As a result, I think it may actually be better for Local Motors to manufacture the products themselves

Nice article! I’d like to explore the argument you bring up about fostering intrinsic values among this community of innovators. Unlike Pfizer, whose attraction to open-innovation via contests among researchers is ultimately driven by its desire to solve issues/create efficiencies within the healthcare space, the lack of intrinsic motivators among innovators in the automotive space may stem from a lack of a broader societal issue to solve. Given this gap, I’d want to understand more about the broader sweeping impacts that these innovators can have and potentially build from here in terms of how I’d market these contests to innovators so that they are compelled to share knowledge and build a stronger sense of community.

Thanks Joaquin. I really enjoyed the article and the exhibits were very helpful to understand it, even when I don’t have previous knowledge of the topic.

One thing I kept thinking about while reading the article are the intellectual property implications and how you are able to create competitive advantages when your information is somehow public to potential competitors. I understand that from a society point of view, open innovation help us to progress in a fast way, however, I struggle on how can you use this as a company without digging your own grave.

Thanks again for the article.

Hi Joaquin! Thanks for all the work put into this – the article is great!

My main concern with this model is scalability. While this open-innovation model seems to reduce the cost of developing and designing a new model, I’m under the impression those designs will tend not to be cost-conscious. While the collective power might be great at having cool designs/concepts, I tend to be a little more skeptical of people’s incentives to keep the bill of materials at a reasonable cost. As a result, I’m under the impression those models would actually have a higher cost/unit and, therefore, only be suitable for a niche market.

What do you think? Do you think this innovation model helps or prevents the company from scaling its production?

A great article and the exhibits are super helpful ! In the age when our generation is often skeptical of established companies like Toyota, using open innovation can be very effectively leveraged by start ups to come up with products that are distinct and really stand apart from what we have seen traditionally. I think letting community members vote on the design decision can serve two purposes: generating buzz and ensuring buy-in from the members. And it is a very cost efficient way to do both. However, I still think a certain level of control should be retained by the company and allowing participants to sell products directly would erode value.