Delivering Jets for Bumpier, Warmer Skies: Boeing’s Supply Chain Pressures from Climate Change

Building Aircraft for a World Grappling with Carbon Emissions

Supply chains must deliver the advanced technology needed by aircraft operators in a world dominated by climate change. Boeing is one of the two largest manufacturers of commercial aircraft in the world. Climate change is not only a business risk for customers of Boeing’s jets: Boeing must alter and strengthen its supply chain to deliver products required by a customer base responding to climate change.

Climate change has two relevant consequences: first, more stringent regulation of carbon emissions, and second, more challenging operating conditions for aircraft. Regulators have continued to tighten carbon regulations around commercial aviation, led by Europe.[1] Fuel-efficient aircraft are essential to meeting these regulatory curbs. Meanwhile, aircraft will have to operate under harsher weather conditions and deliver the same performance: for example, higher temperatures will limit the take-off weight of airplanes. Lighter, more technologically advanced aircraft are needed.

Boeing has to actively engage in mitigation of carbon emissions. Air traffic has doubled in size every fifteen years since 1970, and Boeing predicts delivering more than 41,000 aircraft over the next twenty years.[2] In order to maintain its ability to sell that many aircraft, Boeing needs to improve the carbon footprint of its commercial aircraft. Delivering on more fuel-efficient, technologically advanced aircraft requires a nimble and durable supply chain.

Towards cleaner, lighter jets

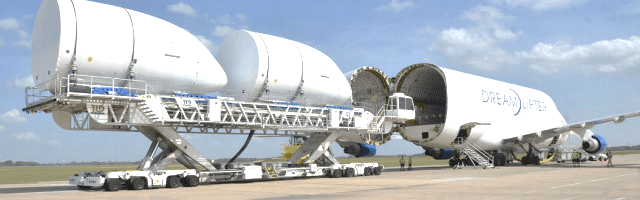

In the short term, Boeing has invested heavily in delivering fuel-efficient jets. This has involved two programs. First, Boeing continues to invest in production of its 787 Dreamliner, a jet made primarily out of carbon fiber. Use of this light-weight material reduces weight and creates a much more fuel-efficient airplane. Second, Boeing has developed new, sophisticated engines that are much more efficient than previous generations. Boeing has committed to delivering legacy versions of aircraft (those without carbon fiber) with these new engines, helping improve fuel economies across its product lines. Meanwhile, over the next ten years, Boeing’s investments in biofuels are a way to reduce the net carbon impact of operating its planes. Boeing has experimented with developing a supply chain for these new fuel sources.[3]

Sourcing each of these necessary innovations requires that Boeing has a top-tier supply chain. Bringing these innovations to market proved particularly challenging in the mid-2000s. Boeing’s 787 arrived more than two years late and had cost overruns of more than $2.5 billion.[4] These costly overruns stemmed from an overly complex supply chain designed to handle the needs of carbon fiber development. Meanwhile, delivering advanced, fuel-efficient engines has stretched the aviation supply chain. Forging specialized metallic parts needed for new, efficient engine designs has proven a costly bottleneck.[5] In short, in an attempt to design appealing products for a world influenced by climate change regulation, Boeing has pushed (and occasionally broken) its global supply chain. Traditional, disparate supply chain models have been unable to cope with delivering these highly advanced and extremely time-sensitive components.

Charting a more sustainable route

Boeing has had some success sorting out supplier hiccups. But it needs to further shore up its supply chain in order to meet the demand for more sustainable, efficient aircraft. Boeing should consider simplifying its supply chain over the next two years. This is not without precedent. In 2009, Boeing ended up acquiring a production plant from a supplier to flatten its supply chain and fix production delays.[6] Ongoing challenges around engine suppliers and future demand for carbon fiber aircraft highlight the continued need for greater control over its supplier base.

Over the next ten years, Boeing needs to take market leadership on two innovations that the market will need in a world impacted by climate change. First, it needs to invest and deploy new technology that can better predict “clear-air turbulence.” This sort of turbulence is nearly impossible to detect using traditional radars. Yet because of rising temperatures, this sort of turbulence will greatly increase – passenger injuries from it will triple by 2050.[7] Second, Boeing needs to spur greater adoption of biofuels. While it has so far moderately supported this new fuel type, Boeing hasn’t kickstarted an ecosystem to support it. Boeing should invest in building a supply chain for biofuels.

As Boeing looks ahead, it must consider two key questions: first, to what extent should Boeing bring manufacturing and supplier networks in-house, versus left to a supplier? And second, to what extent should Boeing seek to kickstart the potentially valuable, but nascent and still-emerging biofuel market?

Word Count: 736

[1] Economist. “Airlines are to cough up for cross-border flight pollution.” October 16, 2016. https://www.economist.com/blogs/gulliver/2016/10/clearing-air

[2] Economist. “Airlines are to cough up for cross-border flight pollution.” October 16, 2016. https://www.economist.com/blogs/gulliver/2016/10/clearing-air

Boeing. Current Market Outlook: 2017-2036. http://www.boeing.com/resources/boeingdotcom/commercial/market/current-market-outlook-2017/assets/downloads/2017-cmo-compressed_091917.pdf, 4

[3] Chad Garland. “Boeing, South African Airways to develop jetfuel from tobacco.” LA Times. August 6, 2014. http://www.latimes.com/business/la-fi-tn-boeing-biofuel-tobacco-20140806-story.html

[4] Economist. “Upwards and onwards.” December 17, 2006. http://www.economist.com/node/15127526

[5] Peggy Hollinger. “Airbus and Boeing put pressure on supply chain.” Financial Times. July 26, 2016. https://www.ft.com/content/e0d51872-516c-11e6-9664-e0bdc13c3bef

[6] Doug Cameron. “Boeing to Boost Dreamliner Production.“ Wall Street Journal. September 13, 2017. https://www.wsj.com/articles/SB124696971307105465

[7] Gavin Haines. “More turbulence and longer runways – seven ways climate change will affect air travel.” Telegraph. October 4, 2017. http://www.telegraph.co.uk/travel/news/ways-climate-change-could-affect-flying.

Thank you for the interesting read. For the aviation industry and its role in the climate change, I believe the ultimate question is who has the bigger responsibility to drive a true change in the industry? Aircraft manufacturers or the operators? I would imagine that the main driver for manufacturers, such as Boeing and Airbus, to develop more efficient aircraft models is to present a more compelling product to the operators to purchase, considering the lower associated fuel costs and also to meet the regulations. However, airlines are still looking at aircrafts from an economic perspective rather than a true environmental one. For instance, although the Airbus A380 model has a lower carbon footprint per passenger flown (due to its higher seating count), airlines were very reluctant to place orders for the same model earlier this month in Dubai Airshow (https://goo.gl/Ri2uYo), and instead opted for smaller Boeing variants. Ultimately, the deciding factor for airlines was the total operating cost of the plane especially in instances when it’s difficult to have enough passenger count to fill an Airbus A380.

OEMs like Boeing and Airbus currently outsource large parts of their manufacturing supply chain to many suppliers across multiple tiers all over the world, but ultimately, Boeing and Airbus have the final decision on the overall aircraft specs that suppliers across their supply chain have to comply with. As you mentioned in your post, the difficulties happen when production is delayed at various points along the supply chain because of how many different steps there are and the many players involved at various points. Also, given the long time frame of aircraft design to order placement to actual manufacturing and delivery, it’s hard for companies like Boeing and Airbus to adapt their planes quickly enough. Advanced tech today may not be so advanced in a few years so it’s critical for Boeing and Airbus to be thinking much farther out in the future.

This is excellent, great work. Clearly Boeing is in a very difficult position right now. I was familiar with the need for more efficient engines and lighter planes, but I was unaware of the impact of climate change on take-off weights and clear-air turbulence. Scary stuff.

Although it will be difficult, I am highly confident that Boeing will, over time, create fuel-efficient engines and lighter, carbon fiber planes. The reason is, as another comment alluded to, Boeing has proper incentives to do so, both in the form of regulation and demand from customers. I am more skeptical, however, of their commitment to biofuels. I wonder if the ethics of a lighter carbon footprint will be enough to incentivize Boeing at a time when it’s already dealing with many significant changes in the industry. Perhaps regulation to this end is the appropriate government response?

This was a fascinating one! I had no idea about either Boeing’s bio fuel experimentation or the notion of clear-air turbulence. The bio fuel work feels incredibly important, especially as climate change hits us full-on and traditional fuels make less and less sense. It seems sensible for Boeing to continue this work and perhaps push for legislation that supports/funds this development. Clear-air turbulence is a particularly interesting effect–unlike many elements of climate change this feels like something that could be used to educate Boeing buyers and the general public on the very tangible impacts of climate change. This would (ostensibly) push demand for Boeing’s climate change work/products, and help push the larger conversation around climate change.

This is a really interesting read! The amount of emissions from the aviation industry are almost the same as those produced by several developed nations in totality and traditionally aviation and shipping industries avoided strong targets in United Nations climate agreements [1]. The effects of climate change such as high temperature operating environment, are now manifesting in actual manufacturing challenges for aircrafts. This might be a blessing in disguise as it will lead to concerted efforts by Boeing and others to reduce emissions and innovate in fuel or efficiency.

I feel the real challenges would be to consolidate the supplier base and reduce net environmental impact at each stage. The value chain for this industry is very broad and spread and each component (example metals as raw material), is responsible for high emissions during its manufacturing stage. The investments of Boeing in lighter aircrafts and fuel efficient technologies is certainly a step in the right direction.

1. http://www.bbc.com/news/science-environment-37573434